Vertical type automatic wall brick sticking device for building construction

A building construction, vertical technology, applied in the direction of building, building structure, etc., can solve the problems of low tiling efficiency, poor applicability of wall tiles, affecting the efficiency of wall tiles, etc., to meet the adsorption effect, improve The effect of suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

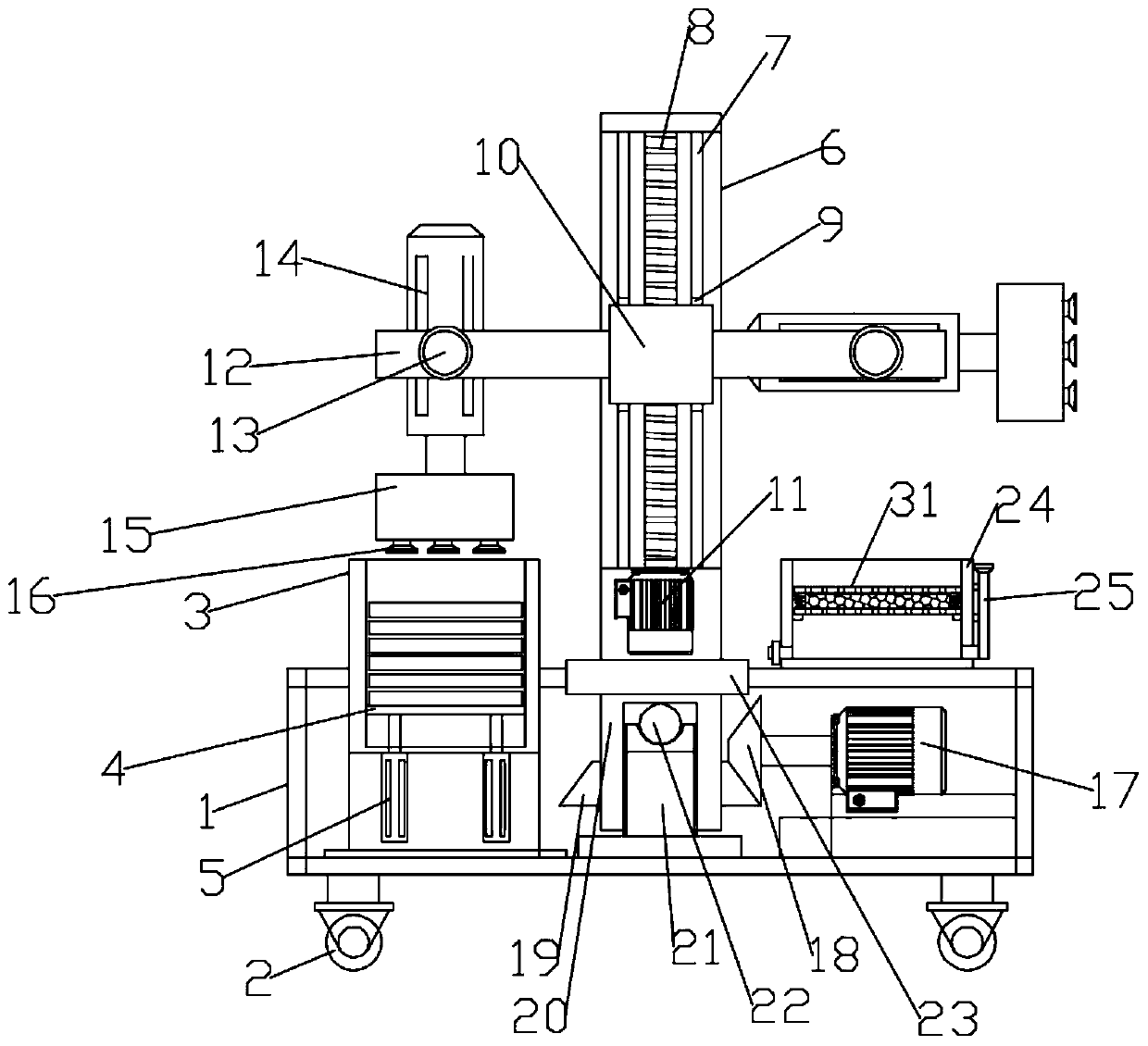

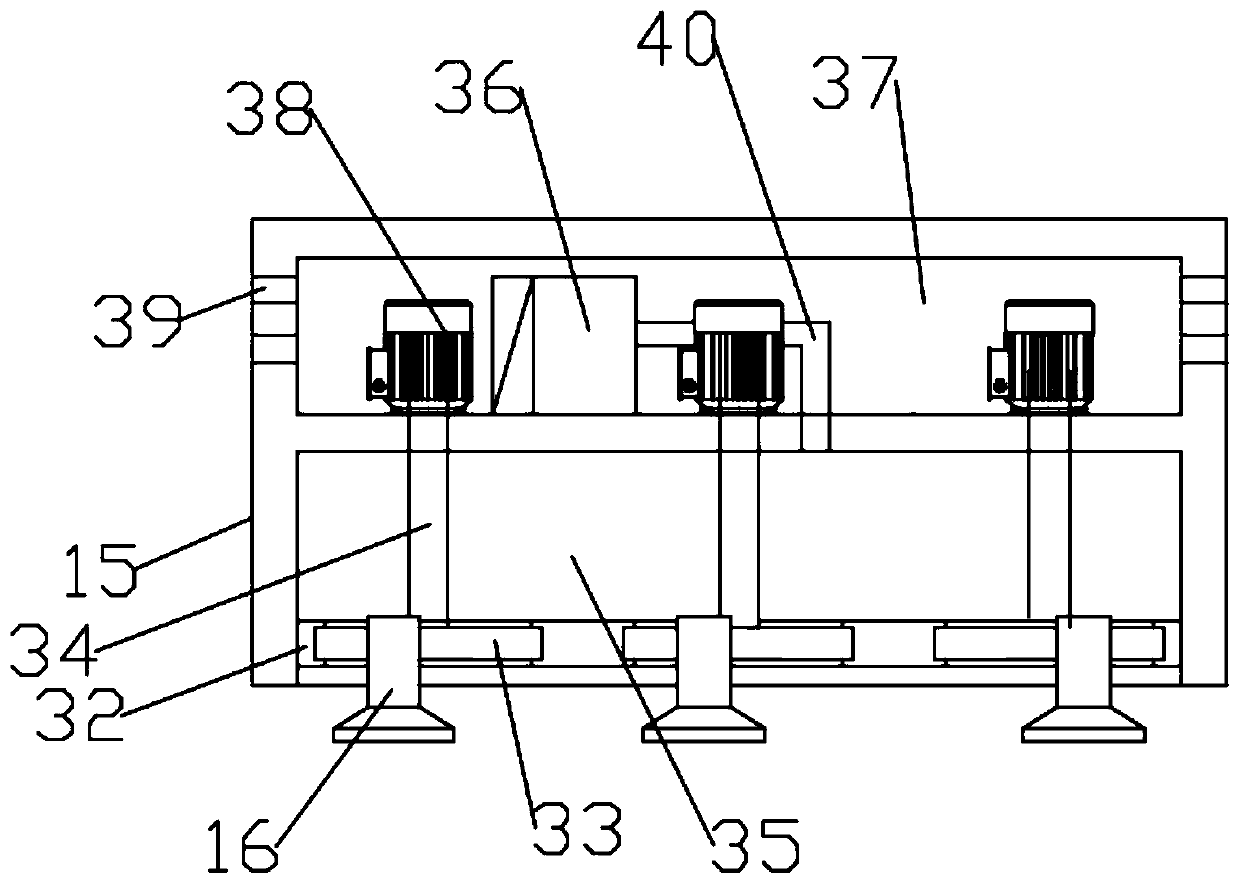

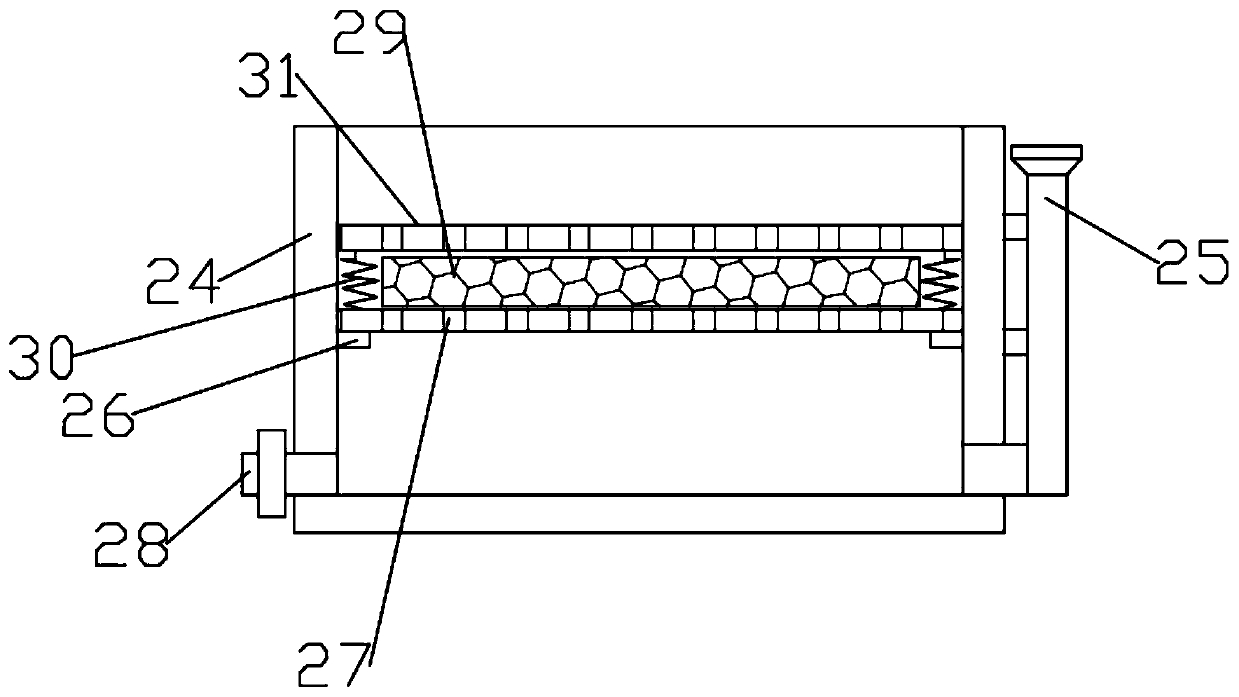

[0039] Such as figure 1 As shown, in the embodiment provided by the present invention, a vertical automatic wall tile installation for building construction includes a support box 1, a brick material tank 3 is provided on one side of the support box 1, and the support box 1 The other side of the rubber tank 24 is provided; the support column 6 is rotated on the support box 1, and the second forward and reverse servo motor 17 for adjusting the rotation angle of the support column 6 is installed on the support box 1 ; The supporting column 6 is provided with a height-adjusting mechanism for adjusting the height position of the lifting seat 10; both sides of the lifting seat 10 are fixedly provided with supporting beams 12, and the two supporting beams 12 are all rotatably set There is a hydraulic telescopic cylinder 14, and an angle adjustment motor 13 for adjusting the inclination angle of the hydraulic telescopic cylinder 14 arranged on it is installed on the support beam 12; ...

Embodiment 2

[0042] Such as figure 1 As shown, in the embodiment provided by the present invention, a vertical automatic wall tile installation for building construction includes a support box 1, a brick material tank 3 is provided on one side of the support box 1, and the support box 1 The other side of the rubber tank 24 is provided; the support column 6 is rotated on the support box 1, and the second forward and reverse servo motor 17 for adjusting the rotation angle of the support column 6 is installed on the support box 1 ; The supporting column 6 is provided with a height-adjusting mechanism for adjusting the height position of the lifting seat 10; both sides of the lifting seat 10 are fixedly provided with supporting beams 12, and the two supporting beams 12 are all rotatably set There is a hydraulic telescopic cylinder 14, and an angle adjustment motor 13 for adjusting the inclination angle of the hydraulic telescopic cylinder 14 arranged on it is installed on the support beam 12; ...

Embodiment 3

[0050] Such as figure 1 As shown, in the embodiment provided by the present invention, a vertical automatic wall tile installation for building construction includes a support box 1, a brick material tank 3 is provided on one side of the support box 1, and the support box 1 The other side of the rubber tank 24 is provided; the support column 6 is rotated on the support box 1, and the second forward and reverse servo motor 17 for adjusting the rotation angle of the support column 6 is installed on the support box 1 ; The supporting column 6 is provided with a height-adjusting mechanism for adjusting the height position of the lifting seat 10; both sides of the lifting seat 10 are fixedly provided with supporting beams 12, and the two supporting beams 12 are all rotatably set There is a hydraulic telescopic cylinder 14, and an angle adjustment motor 13 for adjusting the inclination angle of the hydraulic telescopic cylinder 14 arranged on it is installed on the support beam 12; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com