Special jig for sealing adhesive strip

A technology for sealing strips and jigs, which is used in the fields of assembling auxiliary jig equipment, auto parts production and processing to achieve the effect of easy movement, light volume and accurate fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be further described below in conjunction with specific embodiments.

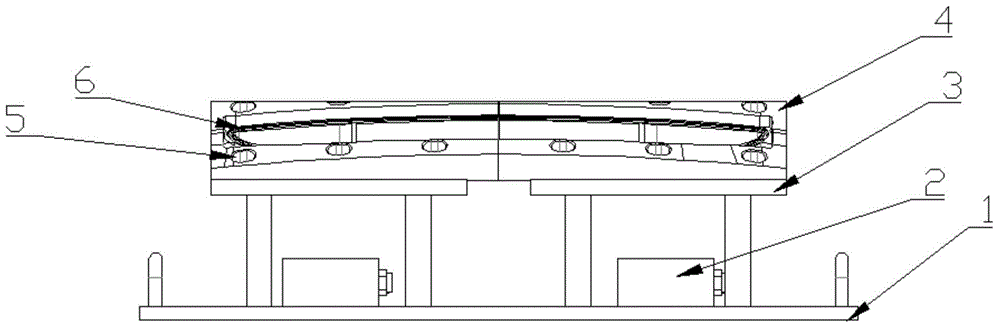

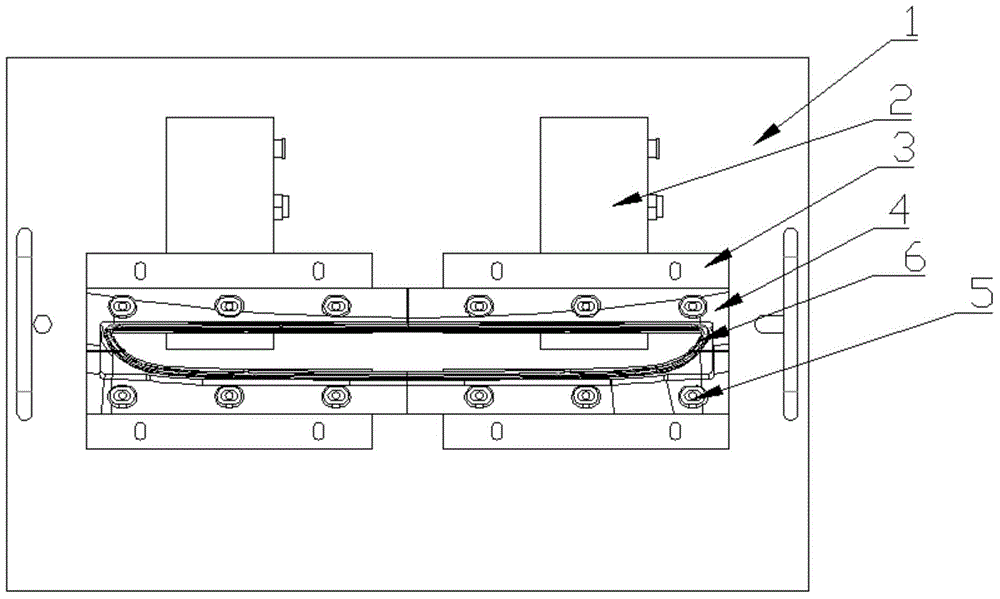

[0017] Such as figure 1 , 2 As shown, the present invention includes a base plate 1, a bracket 3, a lamp block 4, and a vacuum generator 2; the bracket 3 is fixed on the base plate 1; the lamp block 4 is fixed on the bracket 3; the vacuum There are two generators 2, which are placed on the left and right sides and installed under the bracket 3; the lamp block 4 is provided with adsorption holes.

[0018] The invention is made of aluminum alloy material, which is corrosion-resistant and oxidized, anti-friction, easy to install, light in size, easy to move, and suitable for use in various climates.

[0019] Using the invention of the present invention, it is used in the bonding process of the sealing strip of the high-position brake light of the automobile, and the vacuum generator 2 achieves the effect of adsorption, so that the sealing strip 6 below 4mm is accurately and accurate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com