Automatic feeding device for cylindrical rollers

A technology of automatic feeding and cylindrical rollers, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of waste of time for rollers, complex structure, low assembly efficiency of cylindrical roller bearings, etc., and reduce labor costs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

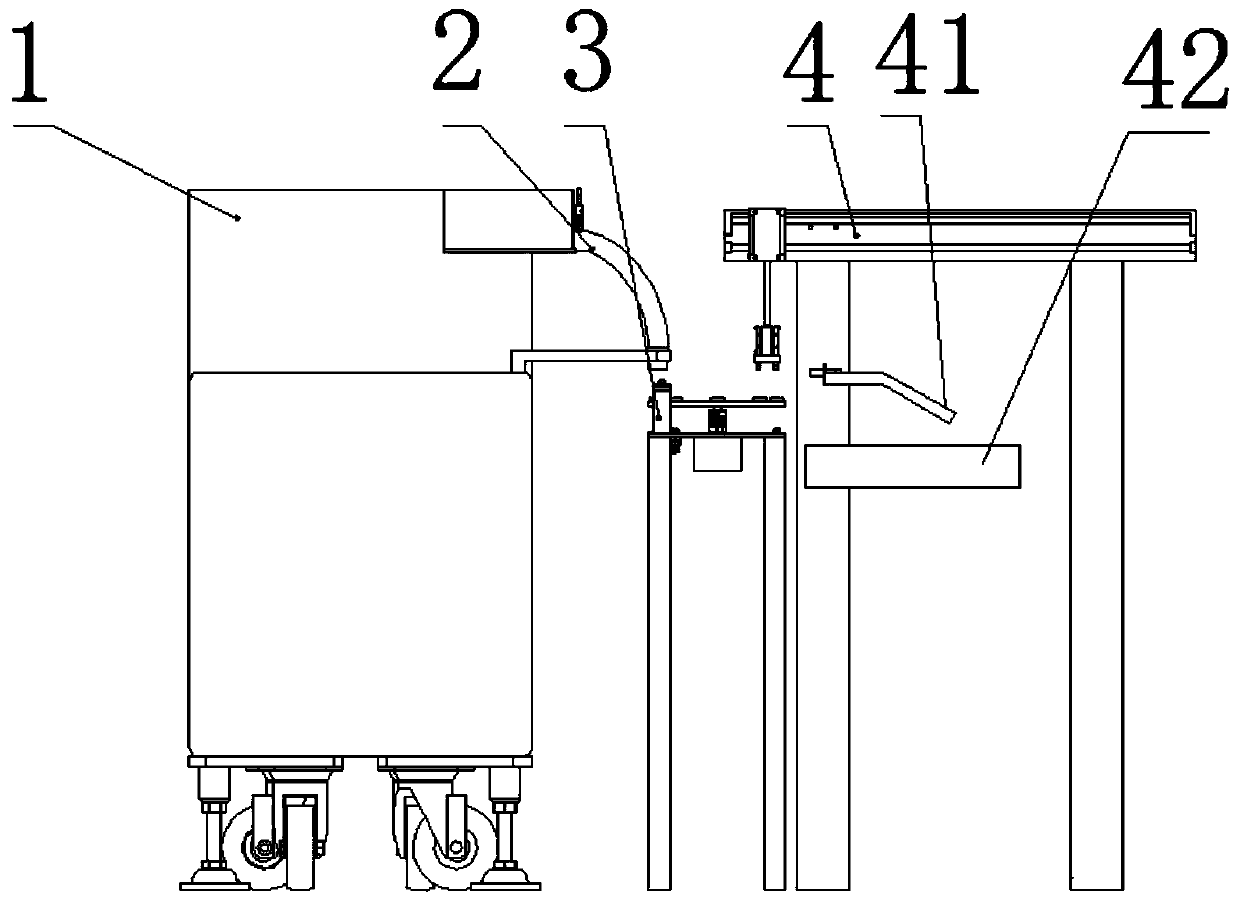

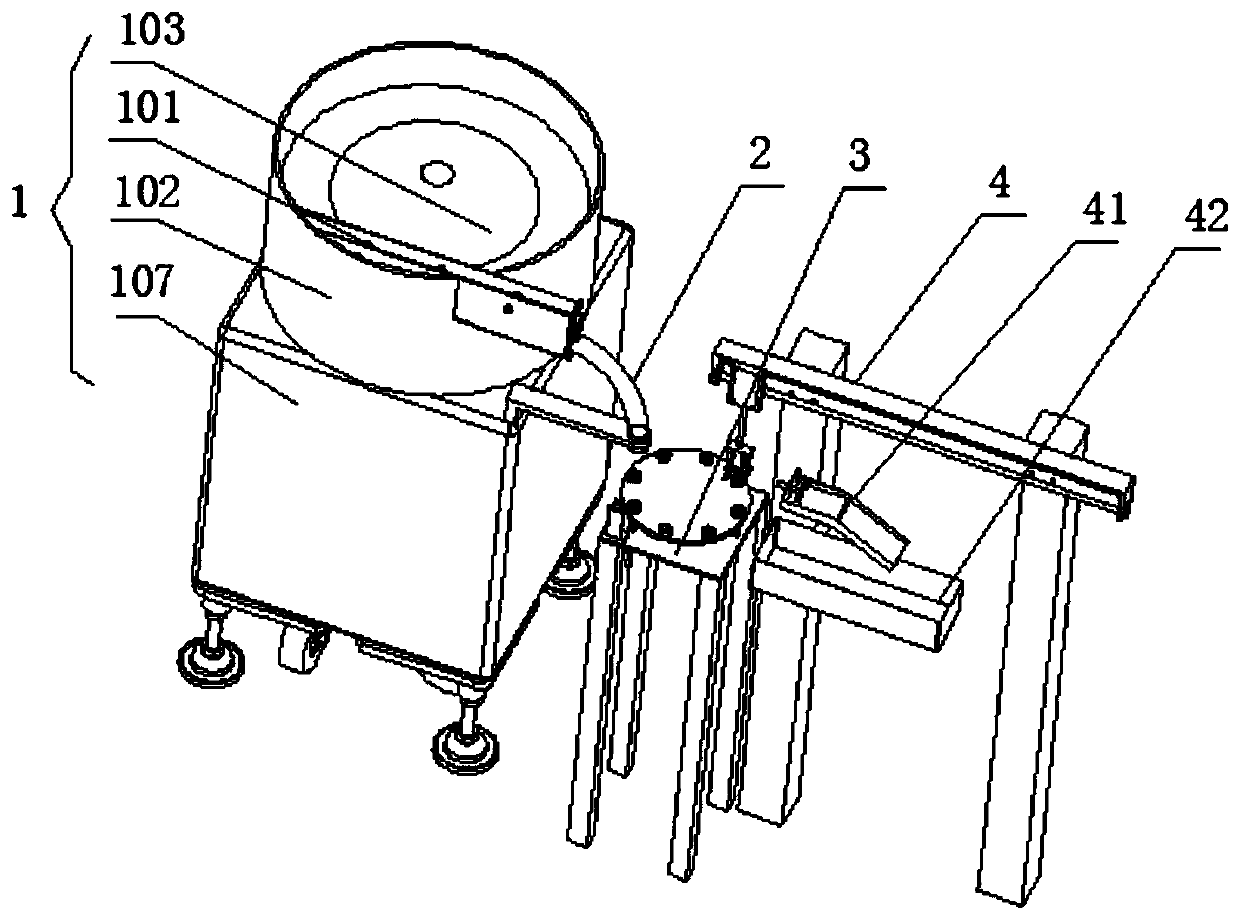

[0035] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides an automatic cylindrical roller feeding device, including:

[0036] The discharge device 1 is used to neatly arrange a plurality of rollers into the same posture; the screening structure 3 is arranged below the discharge end of the discharge device 1, including: a support structure and a drive structure I, and a motor is selected for the drive structure I. The driving structure I is set on the support structure; the turntable I301 is set above the support structure, and is set and fixed on the output shaft of the drive structure I; the positioning structure is set on the turntable I301, which is used to place the rollers to prevent the rollers from moving; the detection device is set on The supporting structure is used to collect the position and appearance information of the rollers on the turntable I301; the unloading structure 4 is arranged above the turntable I301; and the con...

Embodiment 2

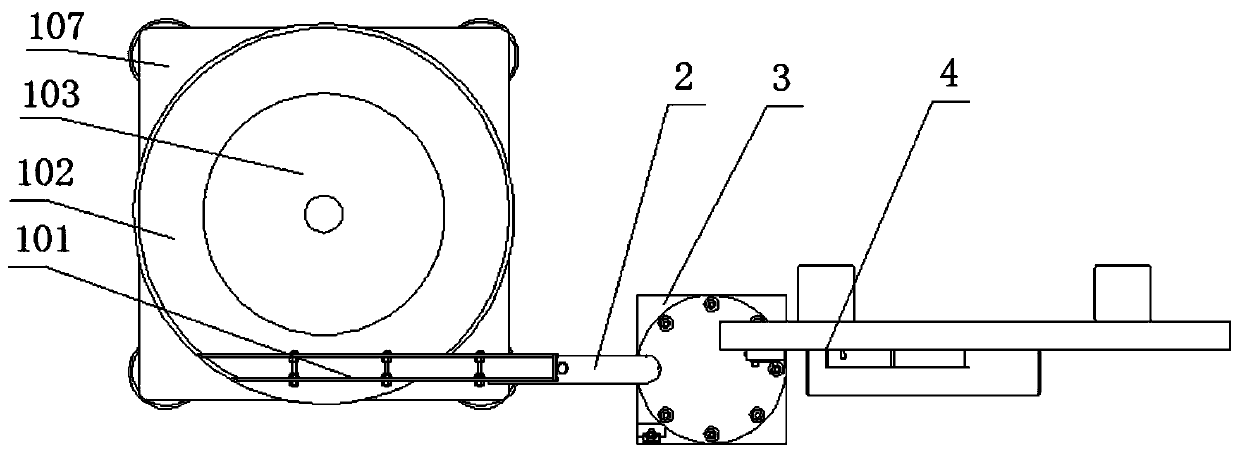

[0038] On the basis of Example 1, such as Figure 4 As shown, wherein, the discharge device 1 selects a discharge device that arranges a plurality of rollers neatly into a horizontal posture, and its specific structure includes a support body 107, and a horizontally arranged turntable II103 is arranged on the top of the support body 107, and the turntable II103 passes through the driving structure. II 106 is driven to rotate, and the drive structure II 106 uses a motor. There is a protrusion in the middle of the turntable II103, and the section of the protrusion is conical. The top is fixed, and the circumferential direction of the baffle 102 is connected with a horizontal track 101. One end of the track 101 communicates with the inner ring of the baffle 102, and the end of the track 101 is located above the turntable I301, that is, when the driving structure II 106 at the bottom of the discharge device 1 is working , so that the rollers in the turntable I301 can enter the tra...

Embodiment 3

[0043] On the basis of Embodiment 1, the discharge device 1 can also be a device that can arrange a plurality of rollers in a vertical posture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com