Two-dimensional pilot-type electromagnetic cartridge valve

An electromagnetic cartridge valve, pilot-operated technology, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as difficult work, sensitive oil pollution, insufficient valve core thrust, etc., to achieve strong anti-pollution ability, drive The effect of large force and low requirement for filtration precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

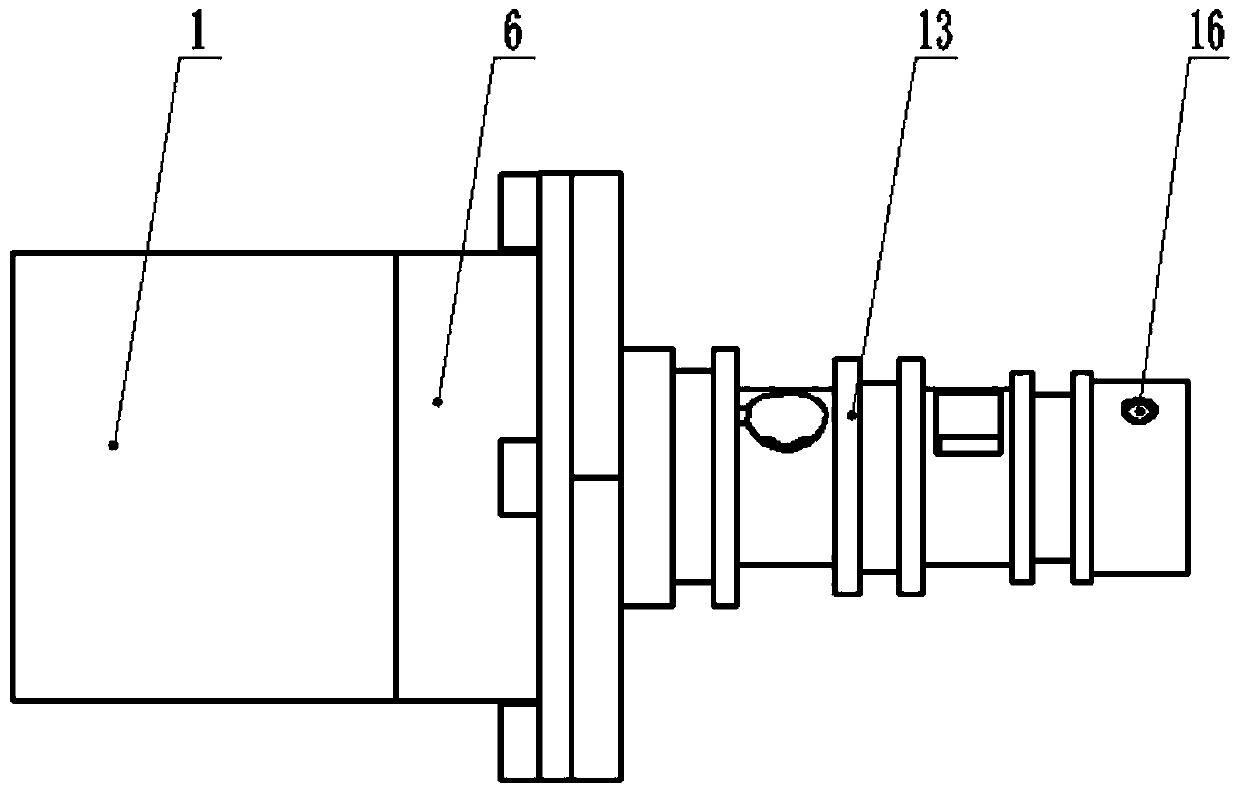

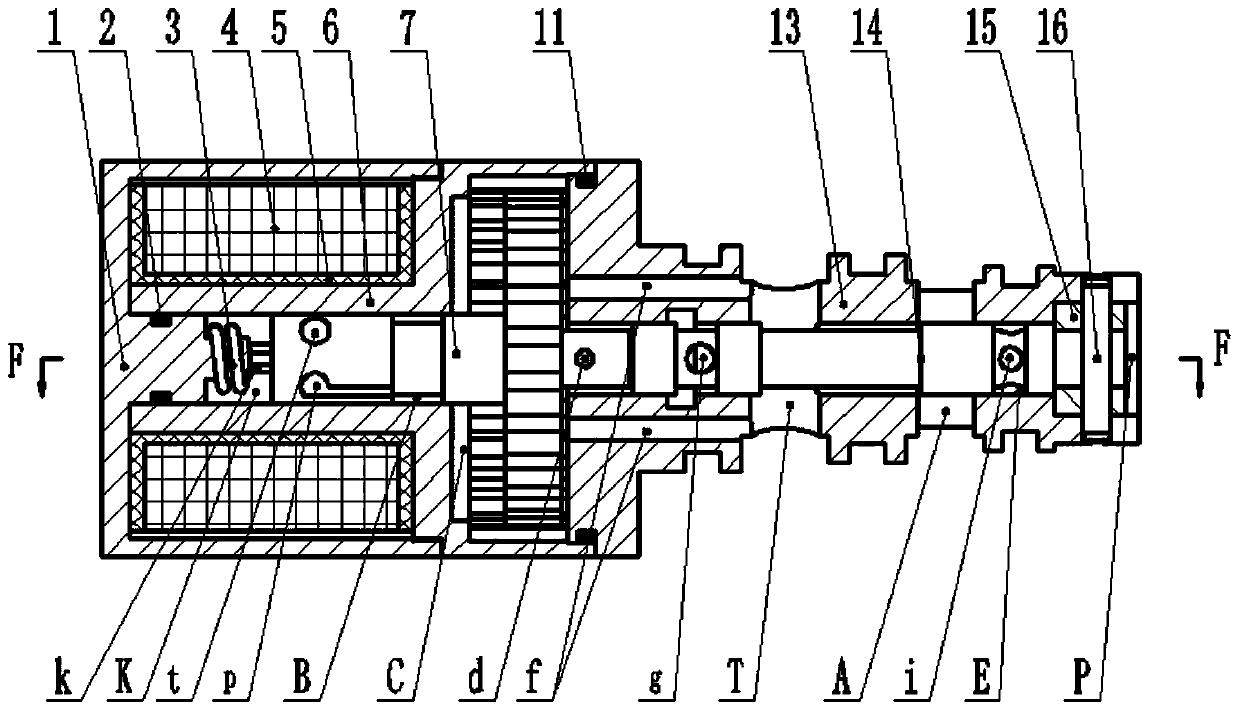

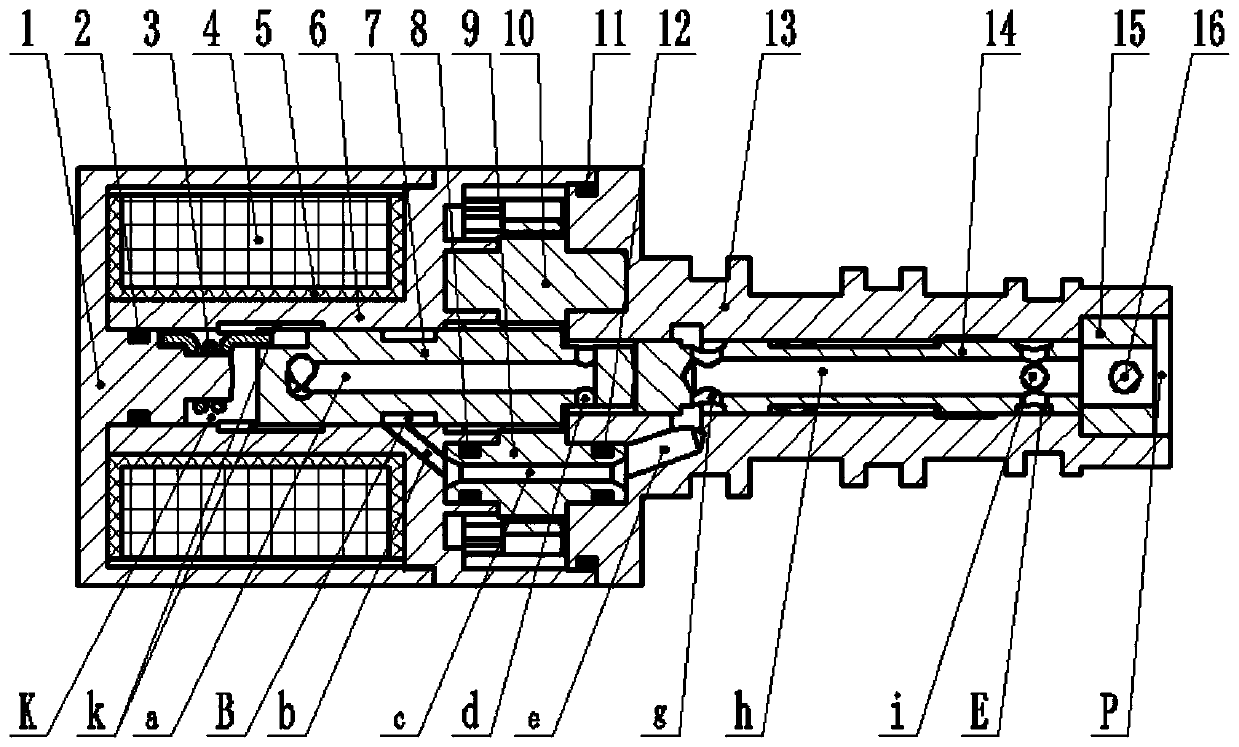

[0041] Refer below Figure 1 to Figure 8b The technical scheme of the present invention is further described.

[0042] The two-dimensional pilot-operated electromagnetic cartridge valve is characterized in that it includes a housing 1, a torsion spring 3, a coil 4, a coil holder 5, a stator 6, an armature 7, a first oil guide block 9, and a second oil guide block 10 , Valve sleeve 13, spool 14, limit ring 15, latch 16, etc. One end of the torsion spring 3 is inserted into the slot 101 on the stepped surface of the convex post of the housing 1, and the other end is inserted into the rectangular slot 71 at the left end of the armature 7; the coil 4 is wound on the coil holder 5 and placed on the stator 6, and inserted into the housing 1 together and Fixed, the shell 1 is connected with the stator 6 through threads; one end of the first oil guide block 9 and the second oil guide block 10 are connected with the circular slots 61 and 62 of the stator 6 respectively, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com