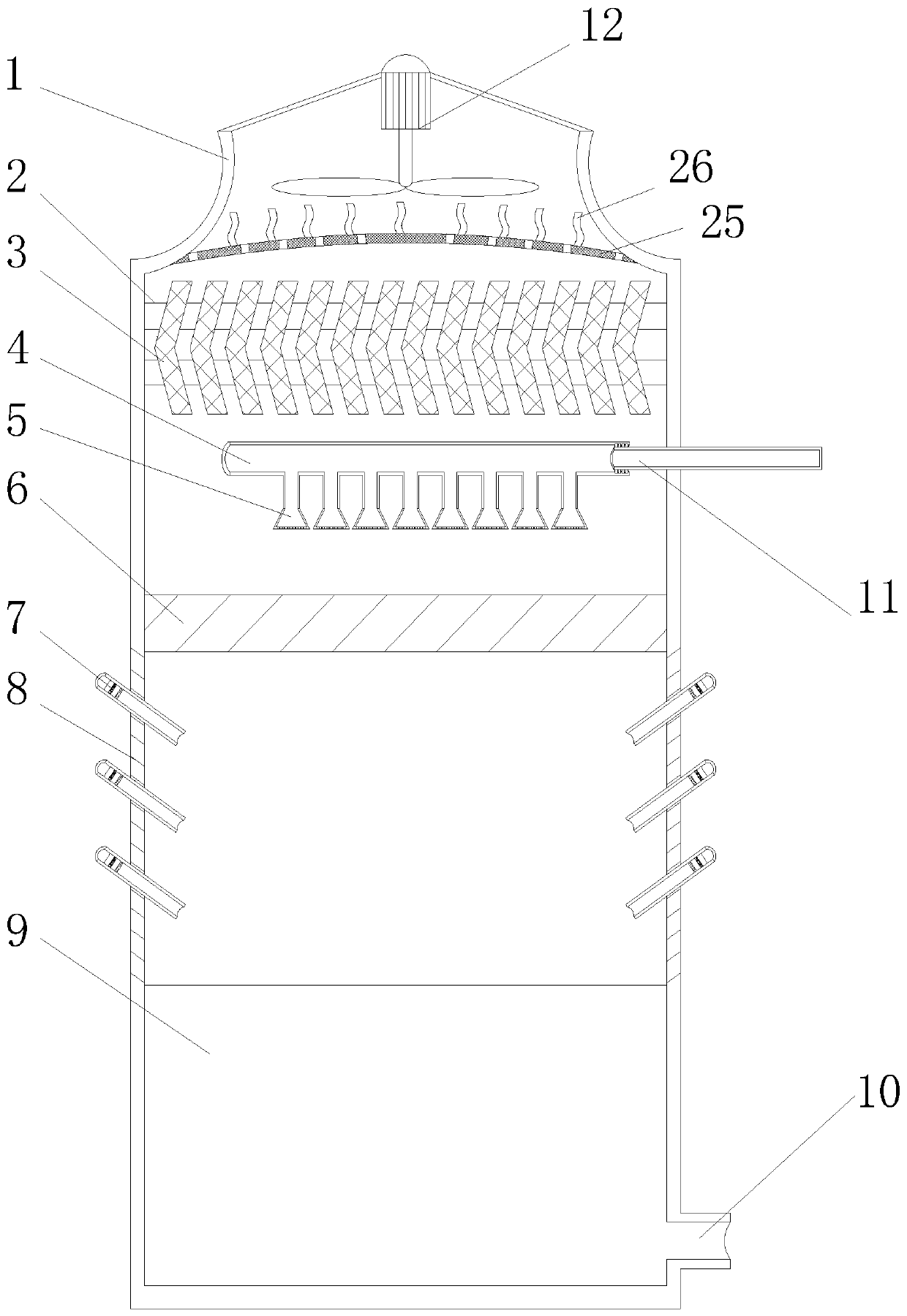

Novel glass-steel cooling tower

A technology of glass fiber reinforced plastics and cooling towers. It is applied in the direction of water shower coolers, heat exchanger types, heat exchange equipment, etc. It can solve the problems of not being able to add water for cooling, cooling speed reduction, and water vapor loss, so as to prevent water loss and improve Cooling speed, anti-loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

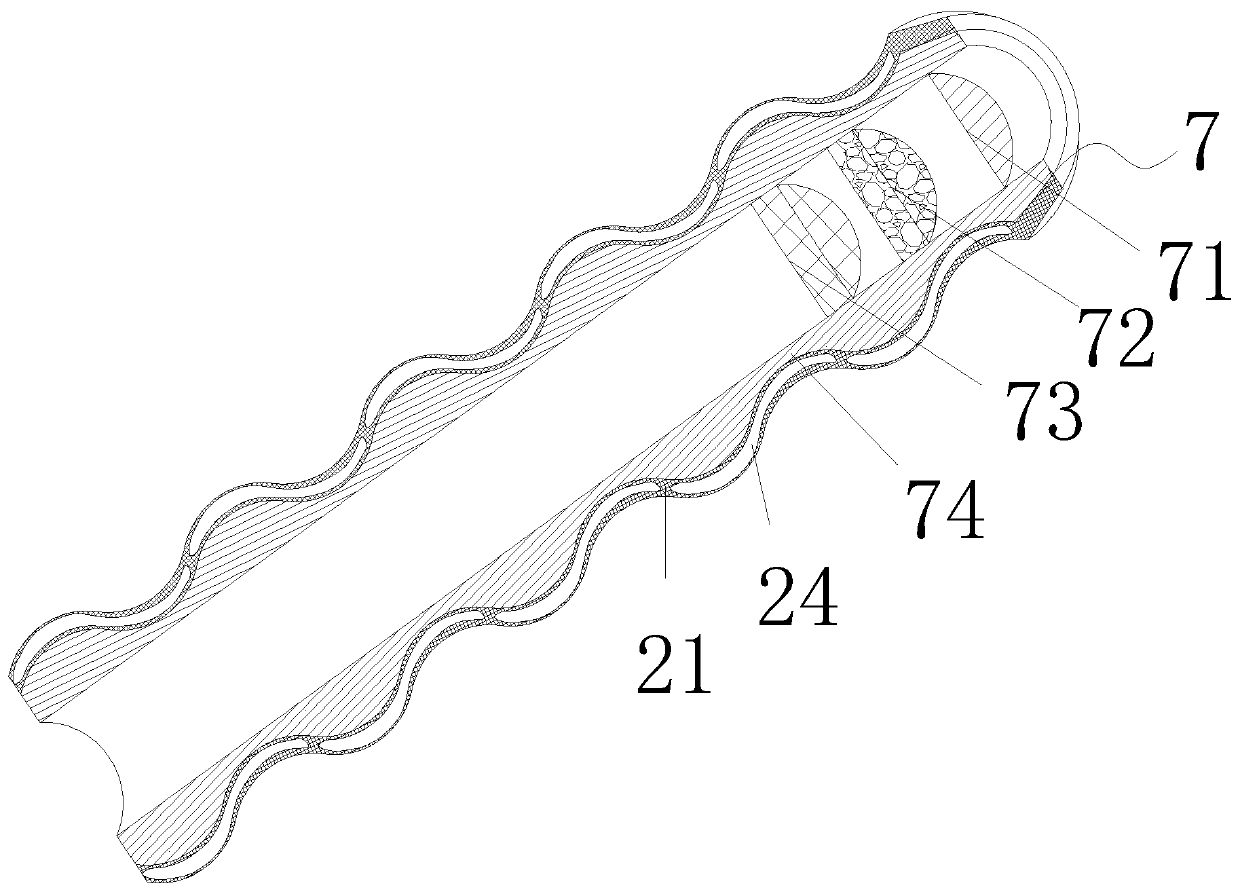

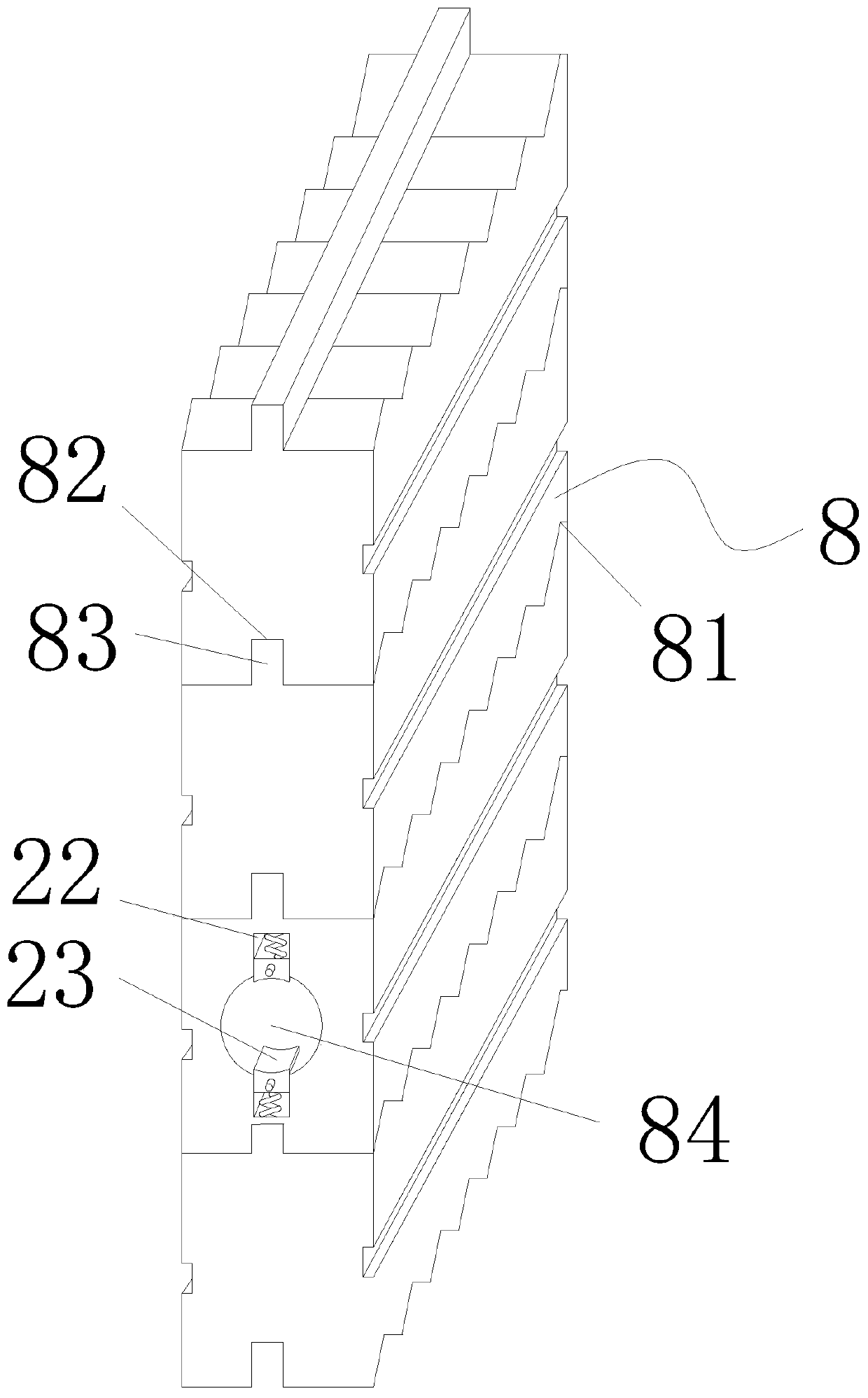

[0029] As an embodiment of the present invention, the rubber layer 21 is provided with uniformly arranged cavities 24, and the cavities 24 are located at adjacent crests and troughs; the shortest distance between the cavities 24 and the crests is smaller than that of the cavities The distance between 24 and the trough, that is, the wall thickness of the cavity 24 at the peak is smaller than the wall thickness of the cavity 24 at the corresponding trough; when working, the block 23 is pressed by the spring force to make the block 23 squeeze the trough of the rubber layer 21, so that the trough The cavity 24 at the place is squeezed, so that the cavity 24 at the corresponding peak is expanded. Since the shortest distance between the cavity 24 and the peak is less than the distance between the cavity 24 and the valley, the cavity 24 at the valley can be expanded farther, thereby The fixing strength of the air inlet pipe 7 and the sealing performance of the air inlet pipe 7 are fur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap