System, testing assembly and method for fatigue testing of wind turbine blade

一种风力涡轮机、疲劳测试的技术,应用在风力发动机的监控、风力发动机、机械部件的测试等方向,能够解决无法用于确定风力涡轮机叶片疲劳测试疲劳目标、疲劳测试不安全、昂贵等问题,达到省时测试方法、精确疲劳测试结果、提高精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

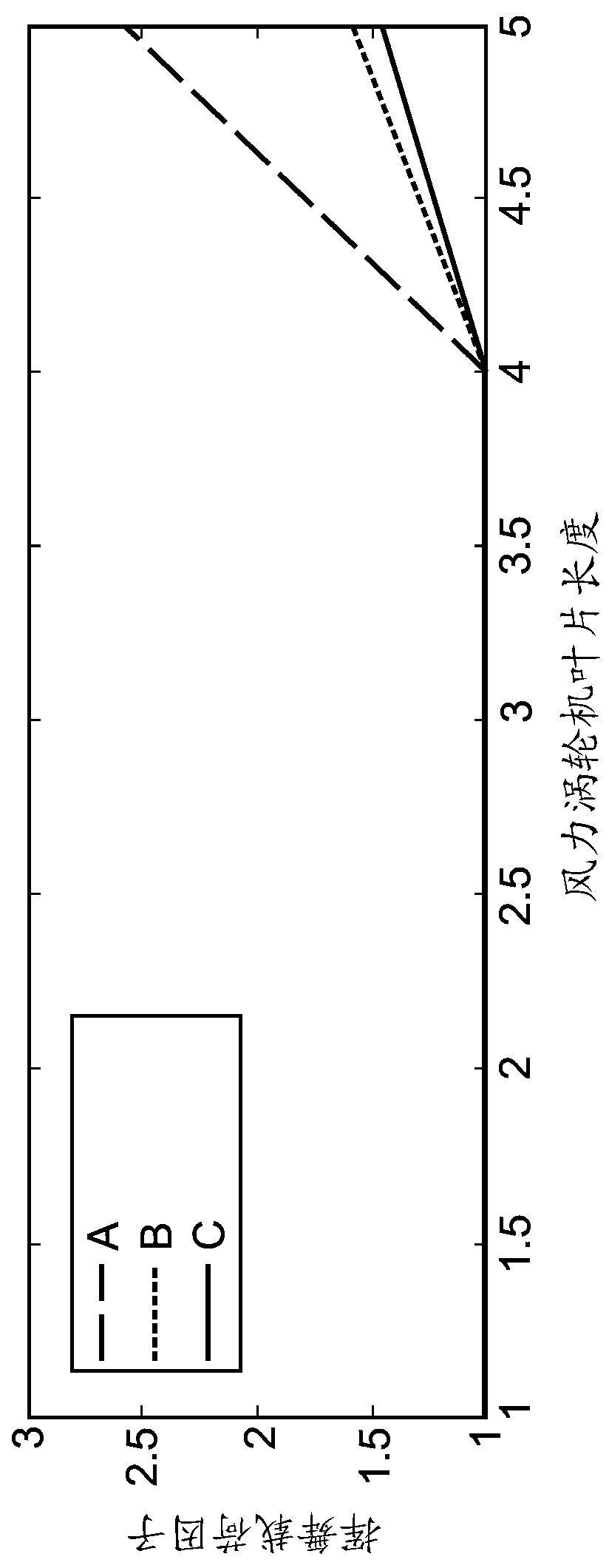

[0031] figure 1 An embodiment of a test assembly according to a first embodiment of the test assembly according to the invention is shown. The test assembly comprises a wind turbine blade 10, the tip 12 of which is shown, but the part of the wind turbine blade 10 close to the root end 11 and the standoff 20 in which the root end 11 is held are not shown in this figure. The test assembly is mounted in a stand 20 such that it is suspended.

[0032] Four loads 60.1, 60.2, 60.3, 60.4 are attached to the wind turbine blade 10 spaced apart from each other. In this embodiment, the loads 60.1, 60.2, 60.3, 60.4 are designed as yokes. In particular, each yoke comprises four rods attached to each other to form a rectangular shape. Two retaining plates are arranged between these four rods. The retaining plate is designed at one side thereof to correspond to the shape of the wind turbine blade 10 at the location where the yoke is attached to the wind turbine blade 10 . The loads 60.1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com