Four-station fireproof door reliability testing machine

A fire door and reliability technology, applied in the field of four-station fire door reliability testing machine, can solve the problems of inconvenient installation, uncontrollable opening angle, hidden safety hazards, etc., to reduce operational risks, realize fault and risk alarm, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

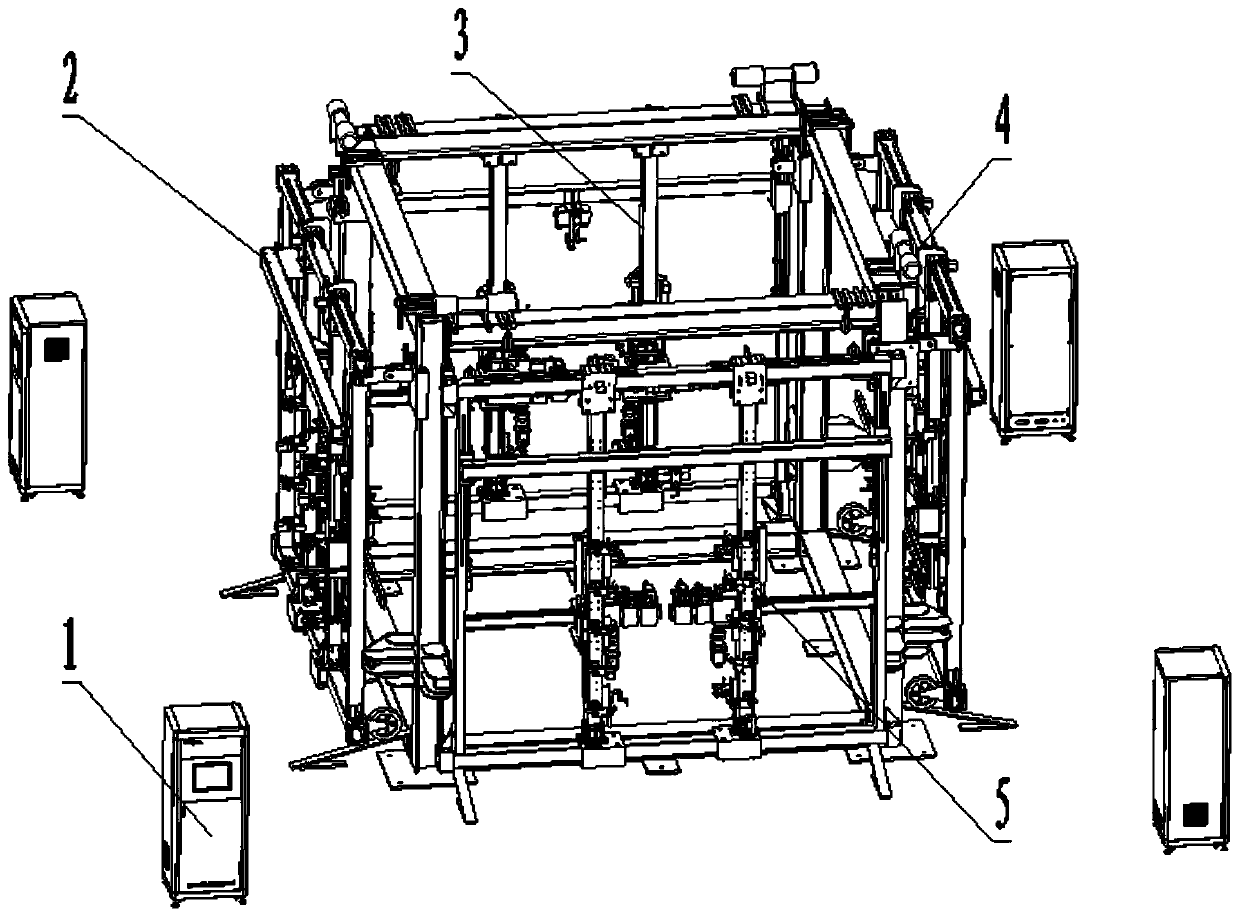

[0019] Such as Figure 1-6 As shown, the four-station fire door reliability testing machine provided in this embodiment includes 4 control cabinets 1 and 4 stations with the same structure, and the 4 stations with the same structure refer to station one 2 and station two 3 , Station 3 4 and Station 4 5, the 4 stations form a cube structure, each station is equipped with a control cabinet 1, and each station can be operated independently.

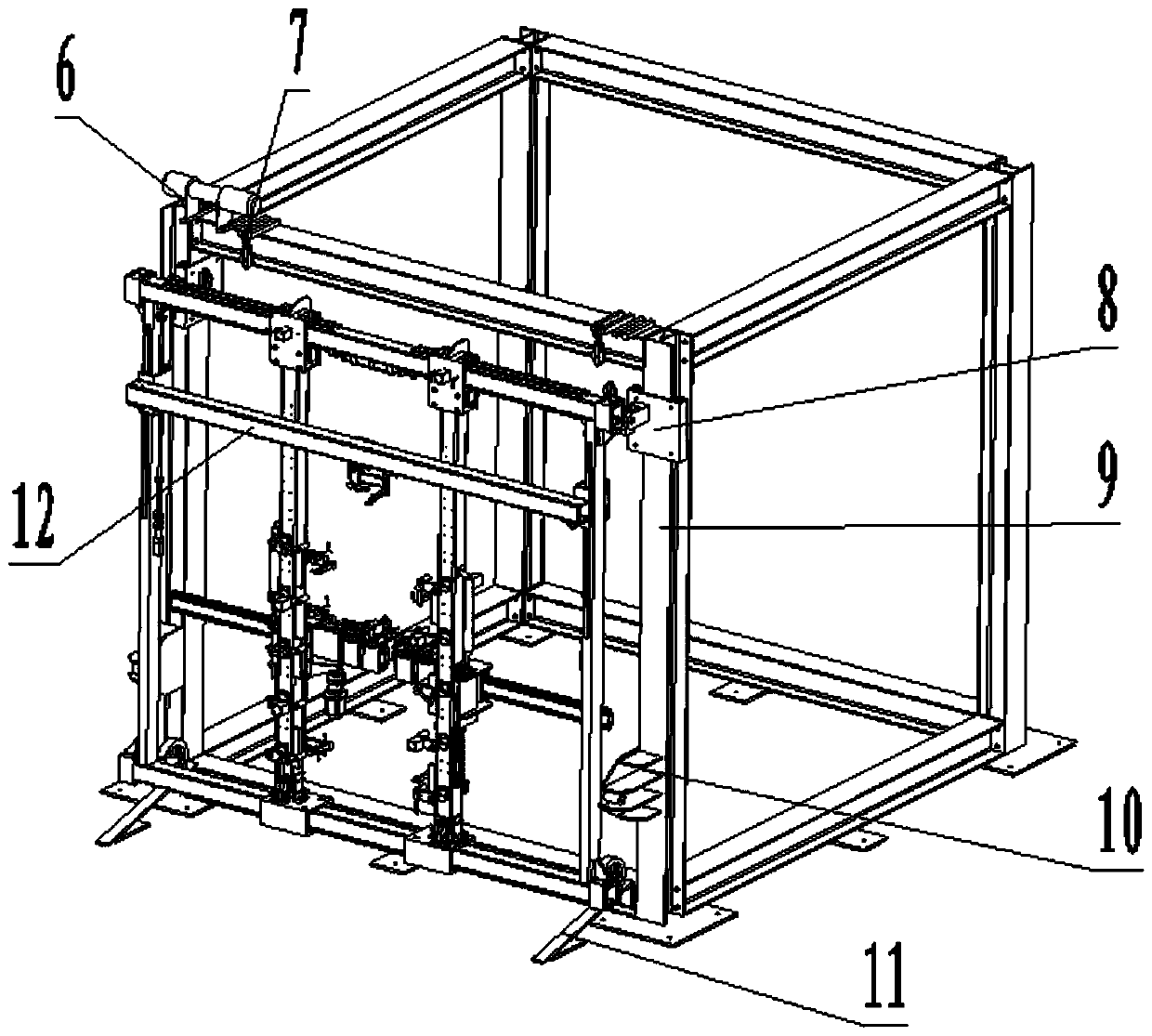

[0020] Such as figure 2 As shown, the station includes a hoist 6, a suspension hook 7, a traction lifting block 8, a latch mechanism 10, an elevator 11 and a movable frame 12, and the steel wire rope of the hoist 6 is connected with the hook 7 to form a movable pulley block, and the movable pulley block passes through its wire rope. Connect with traction lifting tackle 8. Both sides of the top of movable frame 12 are connected with traction lifting tackle 8, and movable frame 12 is driven by traction lifting tackle 8 to lift on equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com