Assembly-oriented intelligent quality tracing method

A quality and intelligent technology, applied in business, instruments, data processing applications, etc., can solve problems such as single traceability method, inaccurate traceability, and untimely traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further explained and illustrated below in conjunction with the accompanying drawings and specific embodiments.

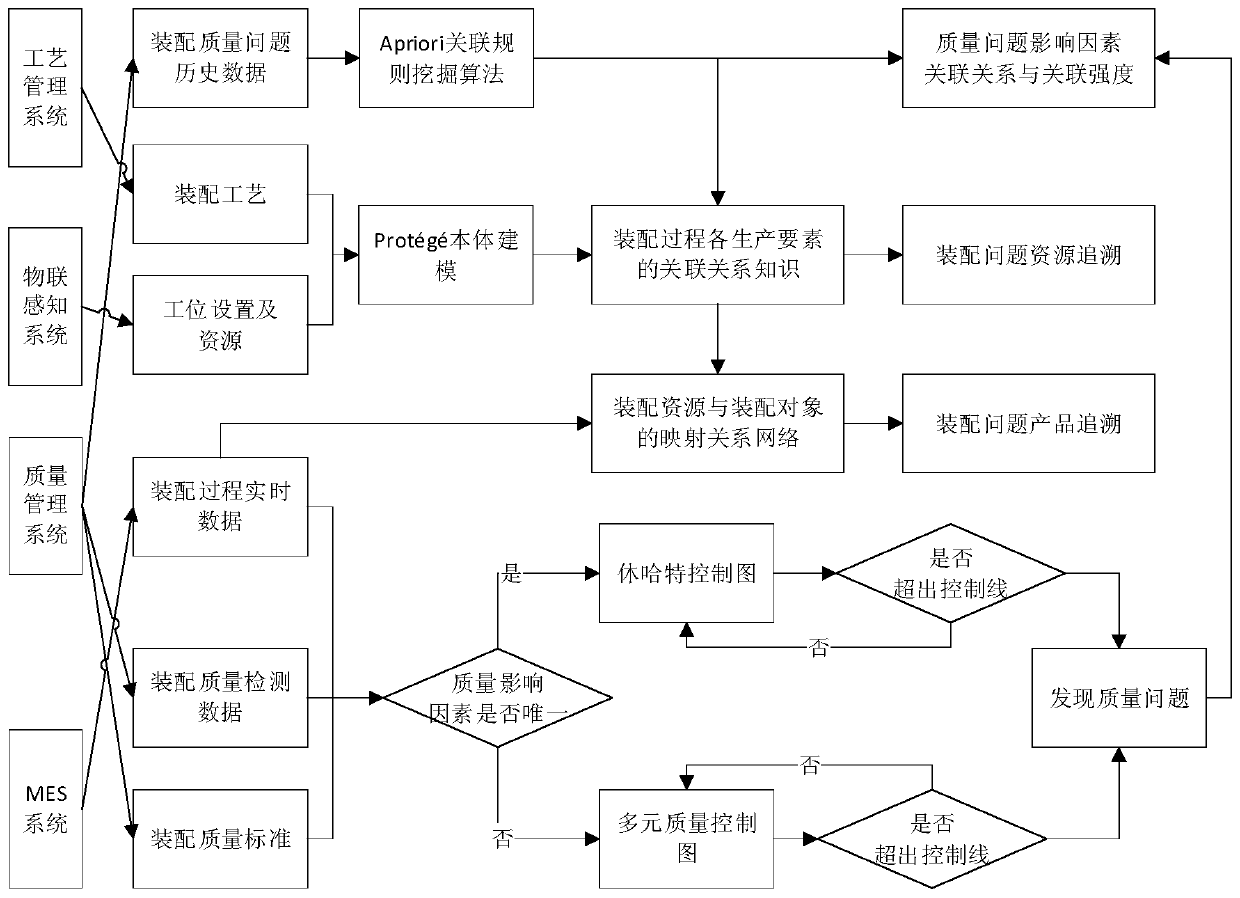

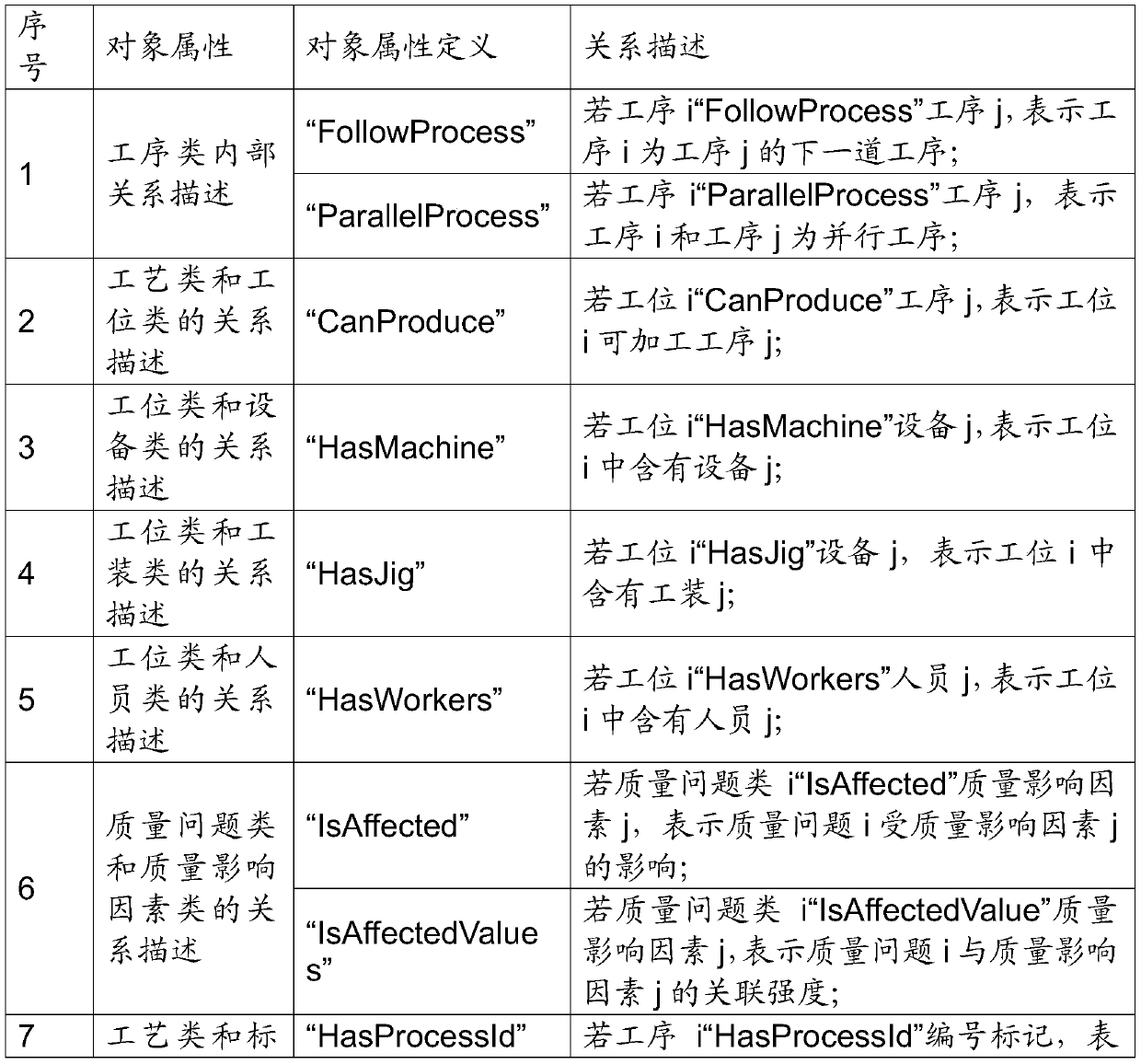

[0041] Such as figure 1 , an assembly-oriented quality intelligent traceability method, including the following steps:

[0042] Acquiring and storing real-time data of assembly process, assembly quality inspection data, assembly quality standard data, historical data of assembly quality problems and models required for quality traceability; the historical data of assembly quality problems includes influencing factors and corresponding historical data;

[0043] Input the historical data of quality problems into the model required for quality traceability, and assemble the quality problem influencing factor correlation mining model, and output the correlation and correlation strength between each influencing factor;

[0044] According to the actual assembly process, and using the strength of the association relationship as the at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com