Thermal shrinkage terminal

A technology of heat shrinkage and terminals, which is applied in the direction of cable joints, electrical components, electrical components, etc., can solve the problems of water vapor ingress, performance degradation and failure of joints, and achieve the effect of tight fit and reduced gap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

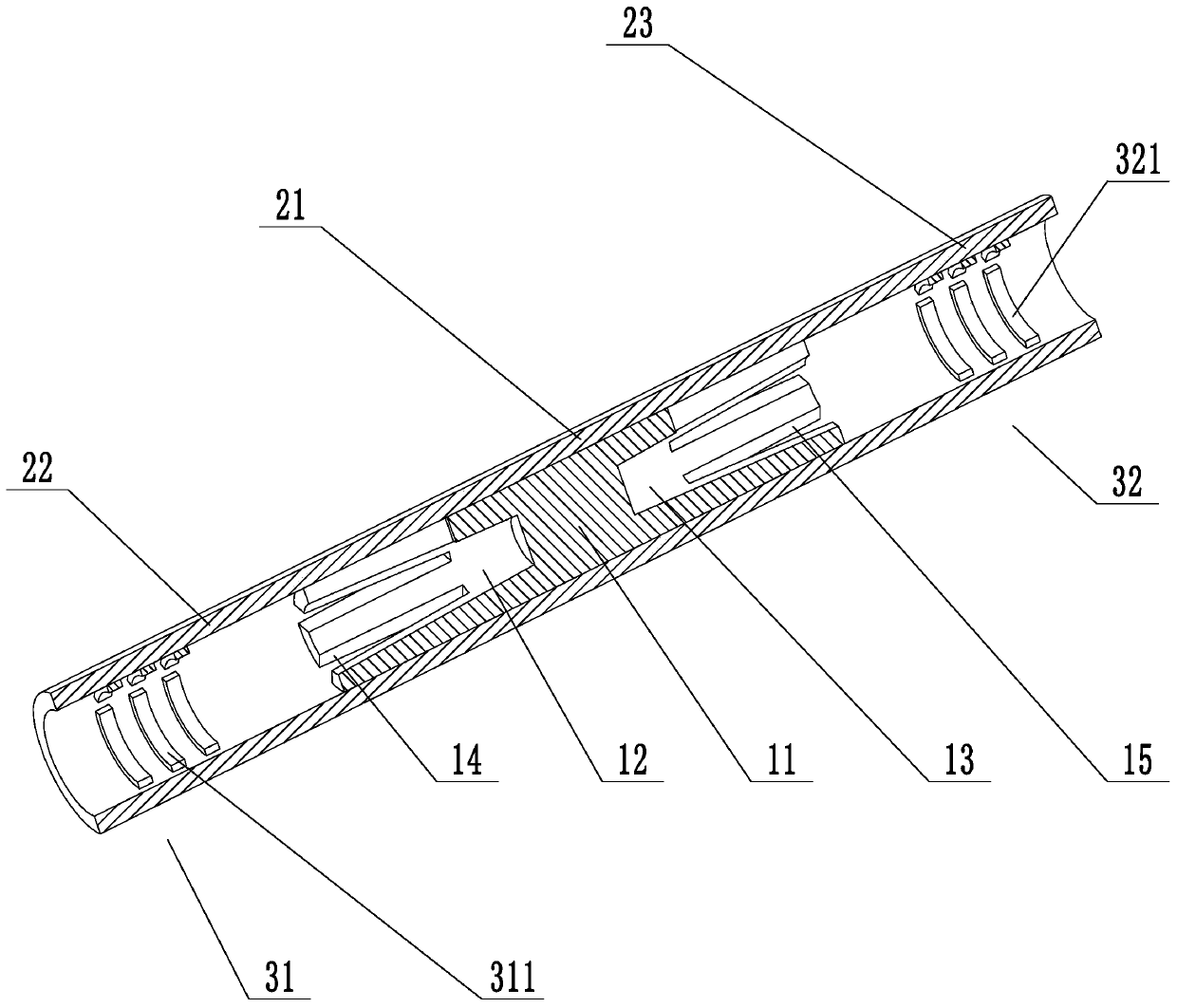

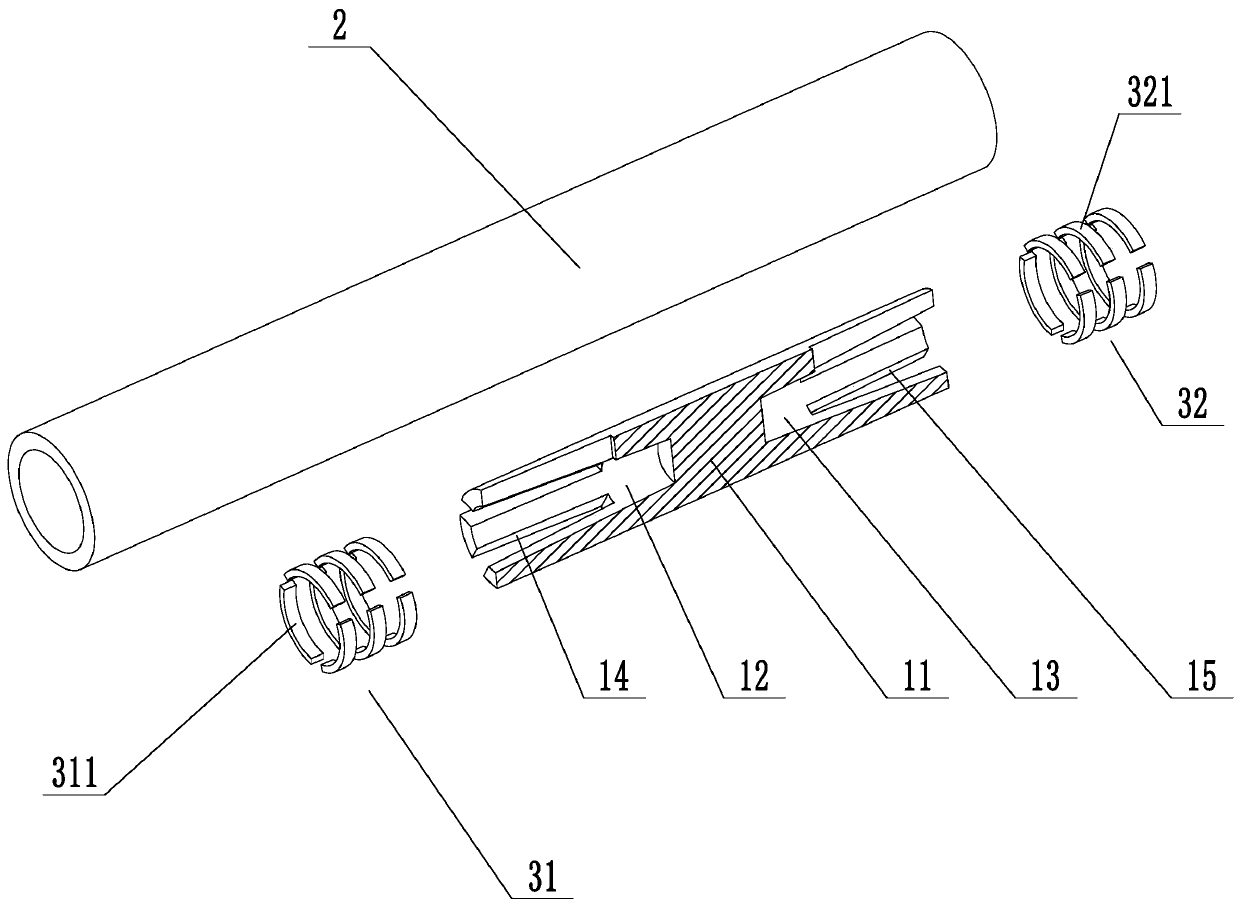

[0047] The application will be described in further detail below in conjunction with the accompanying drawings.

[0048] see figure 1 and figure 2 , is a heat-shrinkable terminal disclosed in the embodiment of the present application, and the heat-shrinkable terminal is mainly composed of a connecting post 11, a heat-shrinkable transparent sleeve 2, a first heat-shrinkable ring 31, a second heat-shrinkable ring 32, and the like.

[0049] The connecting column 11 is cylindrical in shape and has two circular end surfaces and a side surface. A first blind hole 12 and a second blind hole 13 are respectively provided on the two circular end surfaces. The first blind hole 12 The sum of the depth and the depth of the second blind hole 13 is less than the length of the connecting post 11 .

[0050] At least two first long grooves 14 are provided on the side wall of the connecting column 11, the bottom surface of the first long groove 14 communicates with the inner wall of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com