Preassembled pole-mounted distribution transformer district

A pre-installed, platform technology, applied to substations installed on columns and other directions, can solve the problems of inconvenient operation and management, low level of insulation, and many equipment and components in the platform area, so as to improve construction technology and construction safety. level, reduce the construction period, and solve the effect of hidden safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

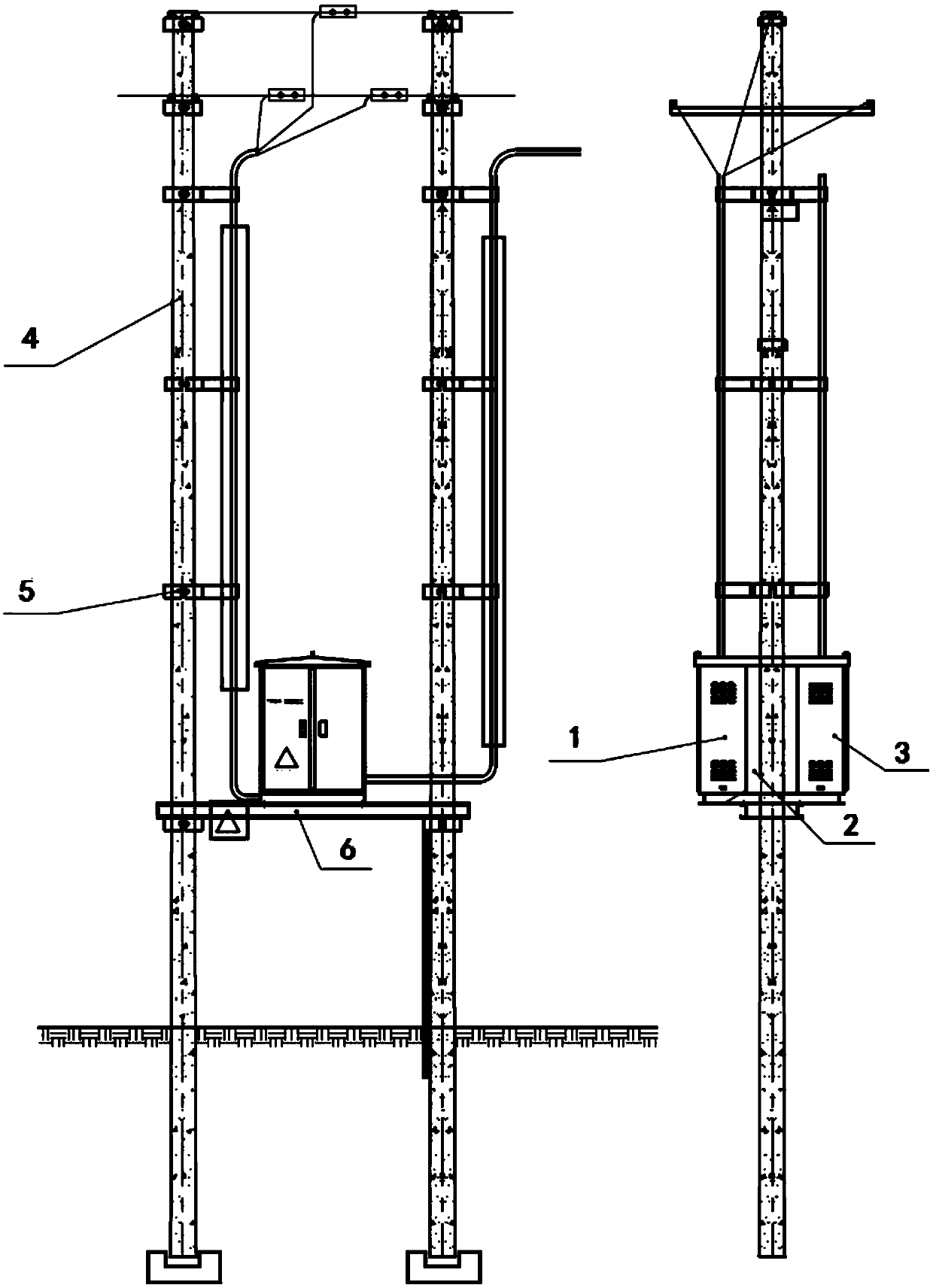

[0035] Such as figure 1 , figure 2 , image 3 As shown, taking the 10KV power supply line as an example, this embodiment provides a prefabricated pole-mounted distribution transformer area, which is installed on the double poles of the rural power grid or urban low-voltage distribution network platform area. Specifically, two double poles The support frame 6 installs the pre-installed post-mounted distribution transformer area on the concrete pole 4. Inside the distribution transformer area, all the interfaces of primary equipment and secondary equipment adopt standardized design to meet the requirements of plug and play . The primary equipment is power transmission and distribution equipment, and the secondary equipment is protection equipment.

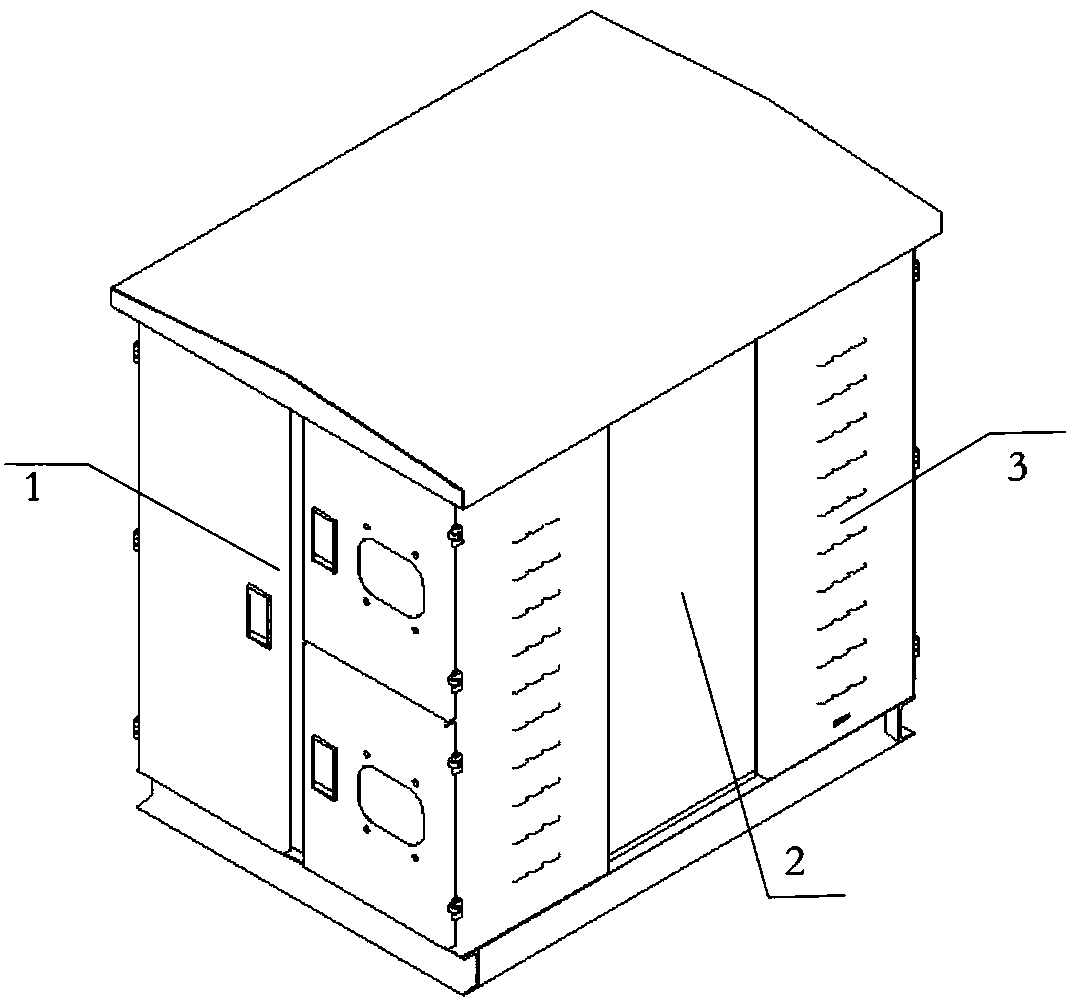

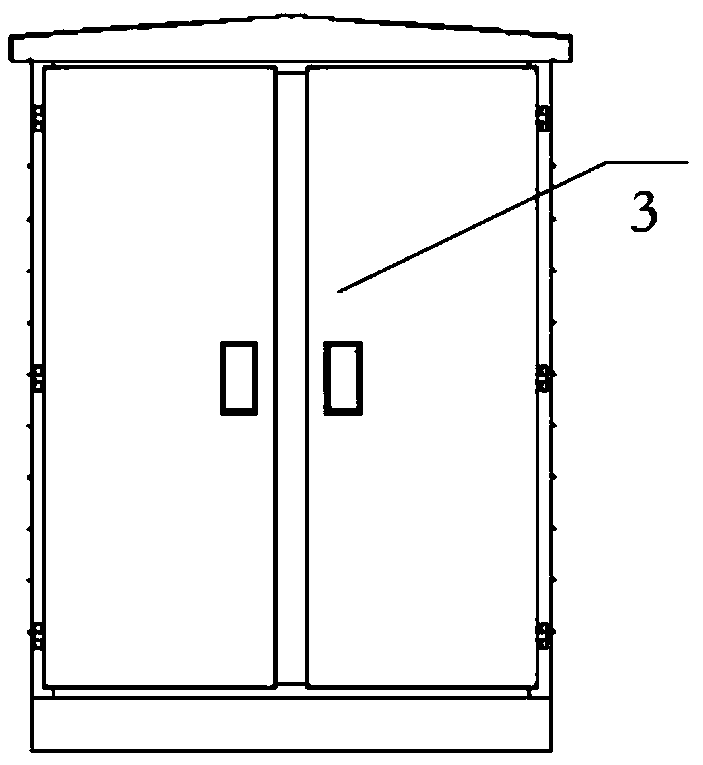

[0036] Such as Figure 2-5 As shown, the pre-installed post-mounted distribution transformer area includes high-voltage unit 1, transformer unit 2, and low-voltage unit 3. The integrated structure design of high-voltage unit 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com