A moving coil type multidirectional vibration linear motor and its realization method

A linear motor, moving coil technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problem of single vibration direction, and achieve the effect of speeding up the stopping speed, flexibility and adaptability, and reducing the stopping time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

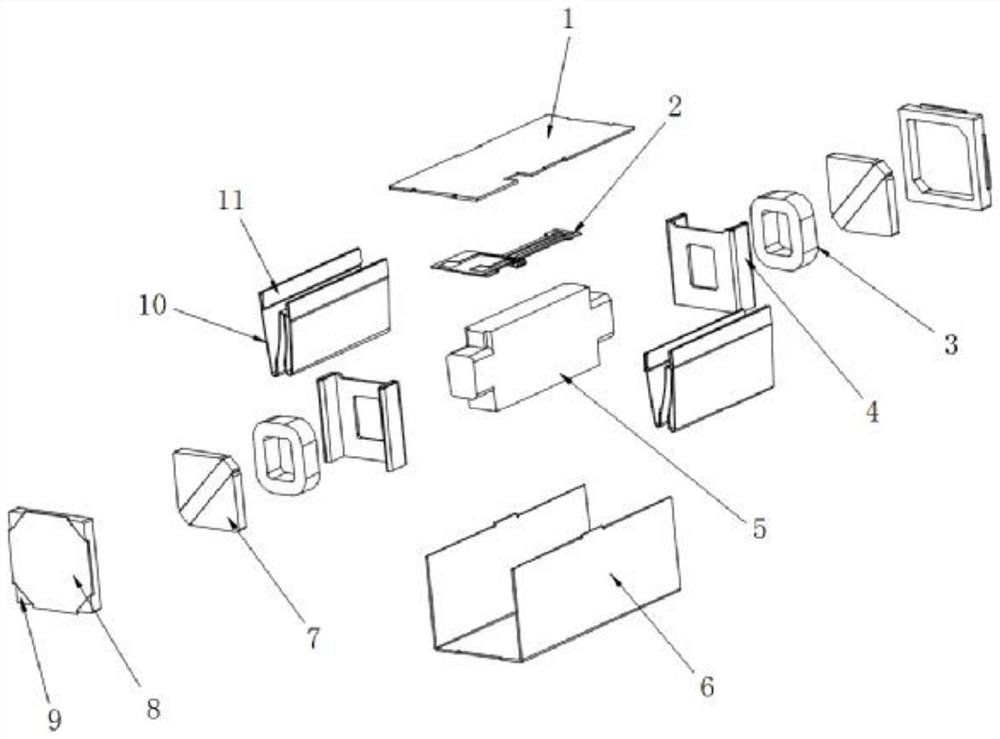

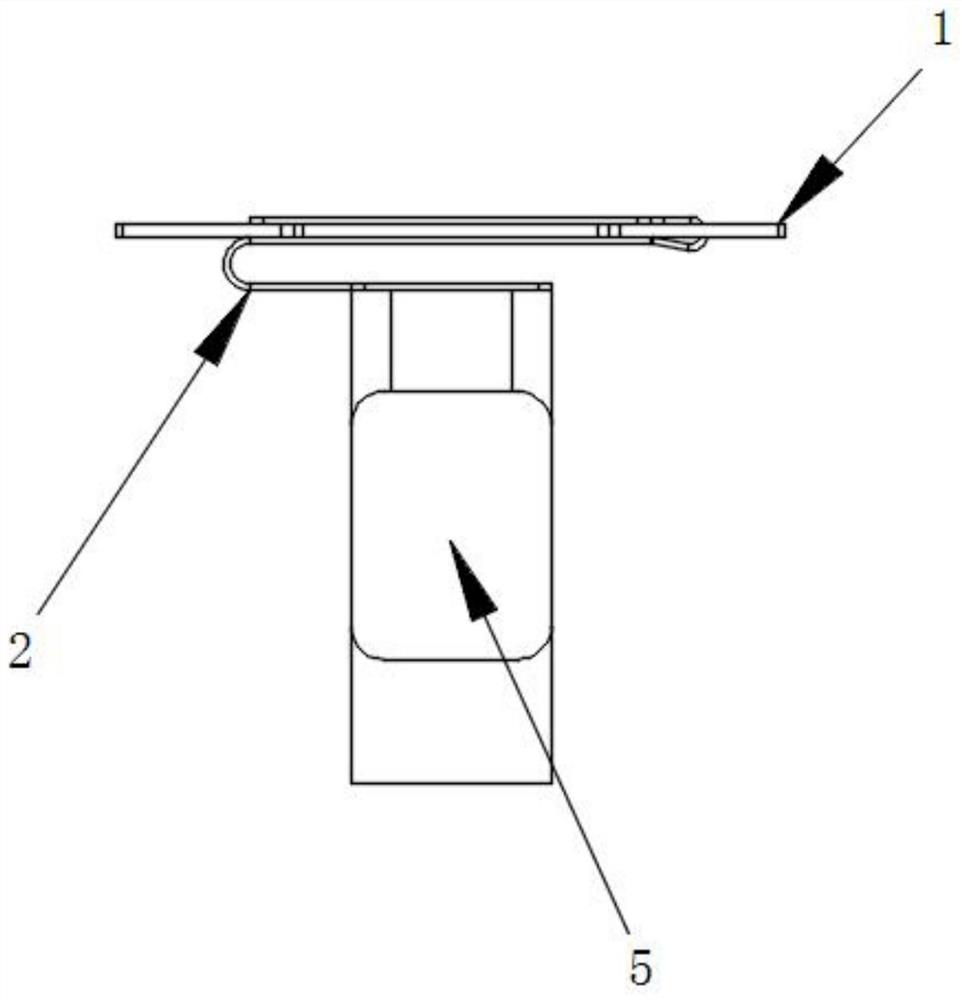

[0037] see Figure 1-10 , the present invention provides the following technical solutions: a moving coil type multi-directional vibrating linear motor, comprising a support frame 6, an upper cover 1 is connected above the support frame 6, side cover plates 8 are connected to both sides of the support frame 6, The inside of the support frame 6 is provided with a vibrator assembly, the vibrator assembly and the support frame 6 are connected by elastic pieces 10, the two sides of the support frame 6 are connected with a stator assembly, and the vibrator assembly includes a soft board 2, a coil 3 and an iron core 5, wherein the iron The two sides of the core 5 are respectively connected to the support frame 6 through the shrapnel 10, the coil 3 is connected to the two ends of the iron core 5, the soft board 2 is connected to the top of the iron core 5, the soft board 2 is connected to the upper cover plate 1, and the coil 3 It is electrically connected with the soft board 2 , and...

Embodiment 2

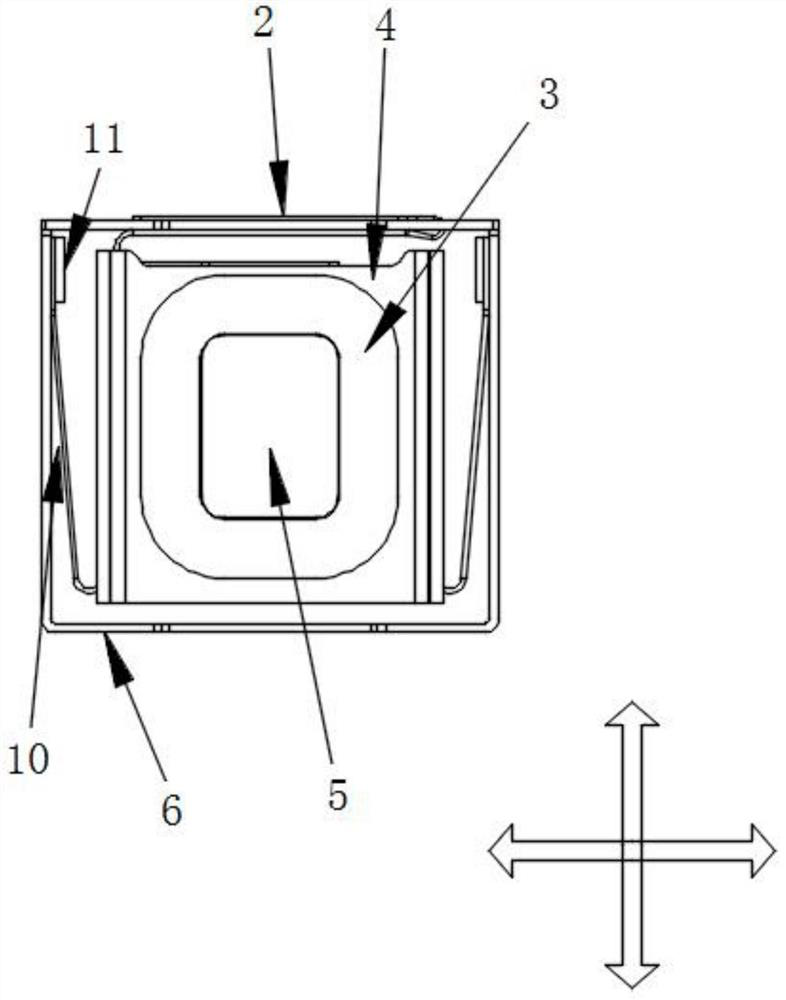

[0050] This embodiment differs from Embodiment 1 in that further, the two outer flat ends of the elastic piece 10 are fixedly connected to the iron core 5 and the support frame 6 respectively, and the two inner flat ends of the elastic piece 10 are respectively connected to a pressure plate 11 .

[0051] By adopting the above-mentioned technical scheme, the shrapnel 10 is a material with relatively large elastic deformation capacity. In this embodiment, stainless steel material is selected, and its special shape design ensures that it can realize linear motion in two directions ( image 3 The direction shown by the middle arrow), and ensure that the modes corresponding to these two motions are in the first two orders, so as to avoid the modes except these two linear motion modes from being excited by the driving signal, and the pressure plate 11 fixes the points formed by the welding process into The surface is fixed, so that the damage caused by the welding process is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com