Method for copying a surface texture of a surface carrier object to an airtight thermoplastic surface layer

A surface texture, thermoplastic technology, applied in vehicle parts, household components, transportation and packaging, etc., can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

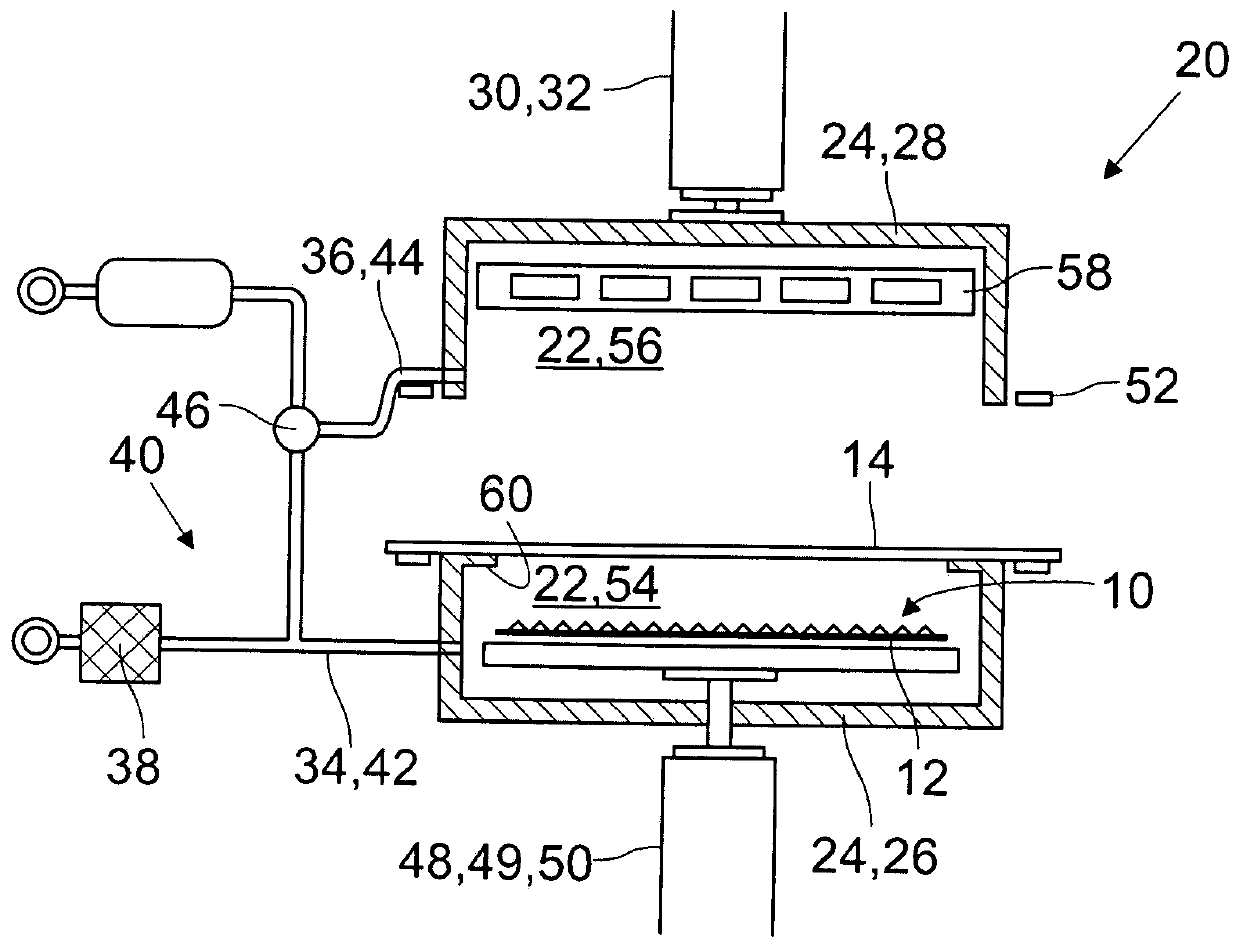

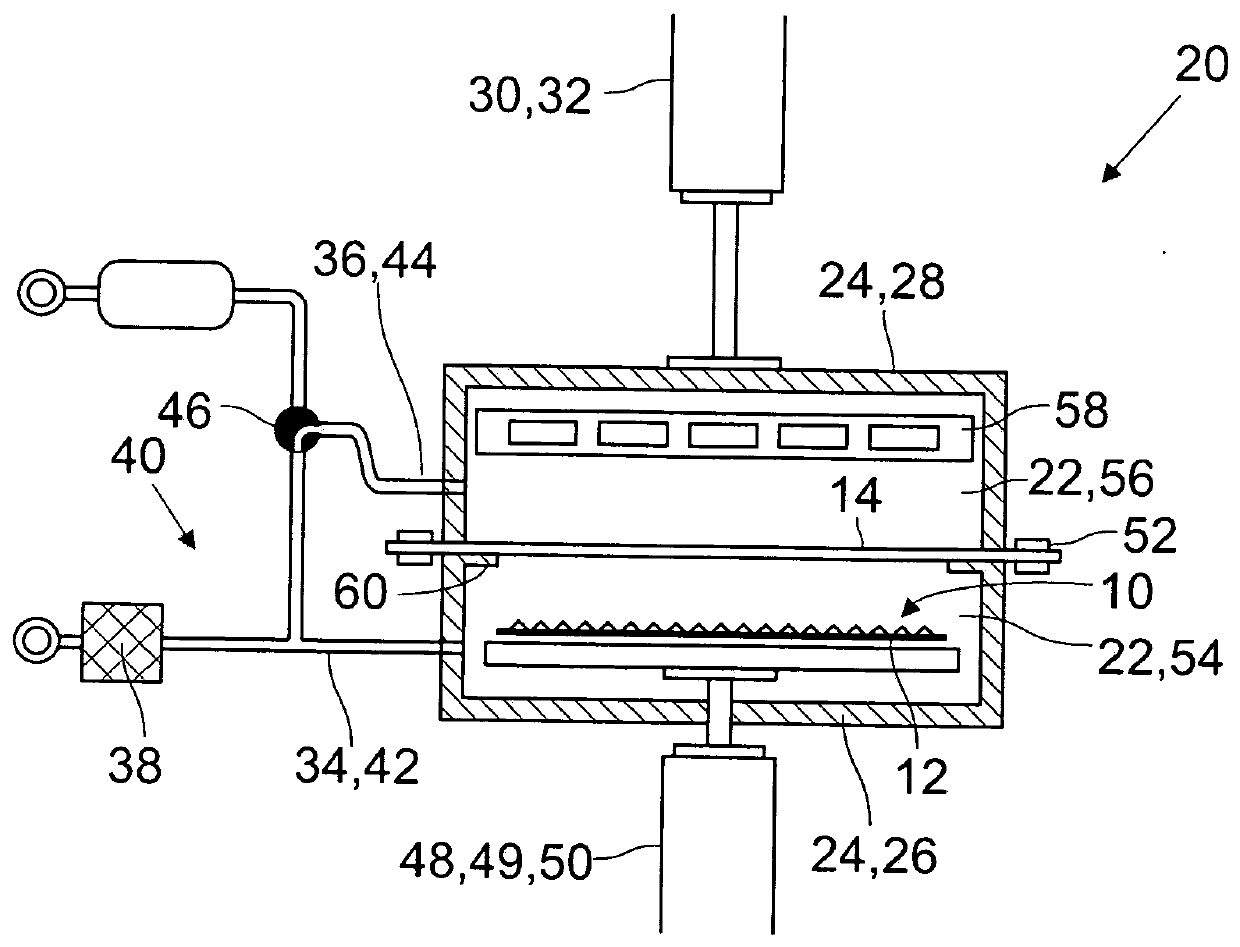

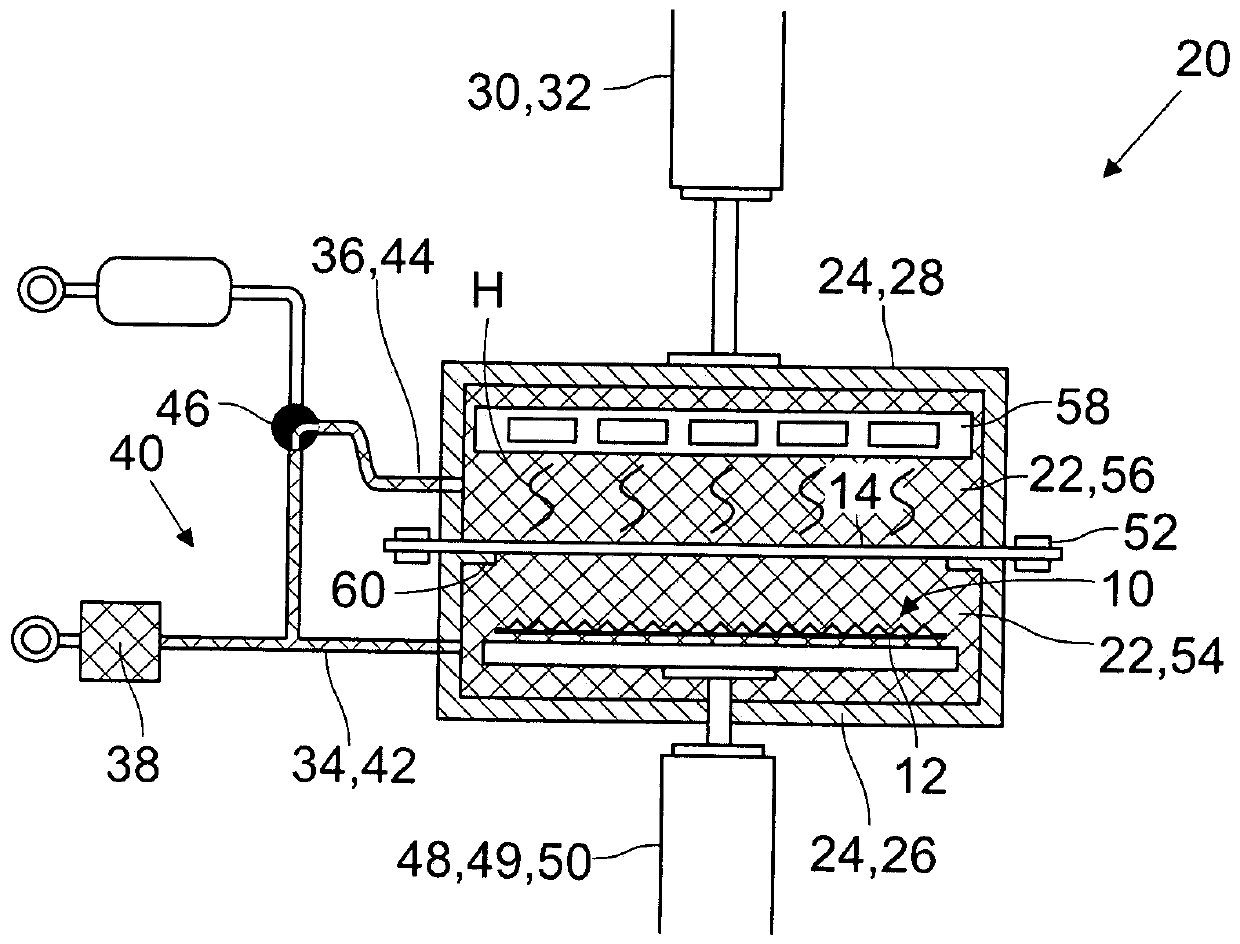

[0052] Reference will now be made in detail to these exemplary embodiments of the present disclosure, examples of which are illustrated in the accompanying drawings. Wherever possible, the same or similar reference numbers are used throughout.

[0053] exist Figure 1 to Figure 6 In, the different steps of one embodiment of the inventive method are used to replicate the surface texture 10 of the surface carrier 12 to the vehicle 18 (see Figure 8 ) of the inner cladding component 16 of the airtight thermoplastic surface layer 14. The method is carried out in a production device 20 which comprises a pressure chamber 22 with a housing 24 which surrounds the pressure chamber 22 . The housing is divided into a first housing part 26 and a second housing part 28 . At least one of the housing parts (shown in the embodiment as the second housing part 28 ) is at a distance relative to the first housing part 26 . figure 1 and Figure 6 open position shown in and in the Figure 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com