A method for measuring the thickness of the copper tube sheath and the outer diameter of the conductor in the cable production process

A measurement method, copper tube technology, applied in the direction of measurement devices, complex mathematical operations, instruments, etc., can solve the problems of high measurement cost, time-consuming, laborious, etc., and achieve the effect of high degree of automation and time-saving measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

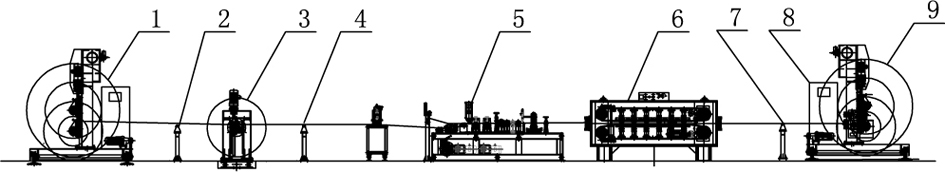

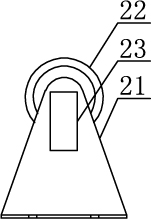

Image

Examples

Embodiment Construction

[0026] A method for measuring copper tube sheath thickness and conductor outer diameter in a cable production process, the measuring method comprising the following steps:

[0027] 1) Enter the copper tube sheath thickness calculation formula and / or the conductor outer diameter calculation formula into the data processor,

[0028] The formula for calculating the thickness of the copper tube sheath is:

[0029] ,

[0030] The formula for calculating the outer diameter of the conductor is:

[0031] ,

[0032] In the above formula:

[0033] H—Finished cable copper tube sheath thickness

[0034] D—Outer diameter of finished cable copper tube sheath

[0035] W—the width of the raw copper strip

[0036] h—the thickness of the raw copper strip

[0037] d—the outer diameter of the finished cable conductor

[0038] d 1 - the diameter of the raw copper rod

[0039] v 1 - Finished cable output speed

[0040] v 2 - Feeding speed of raw copper strip

[0041] v 3 —The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com