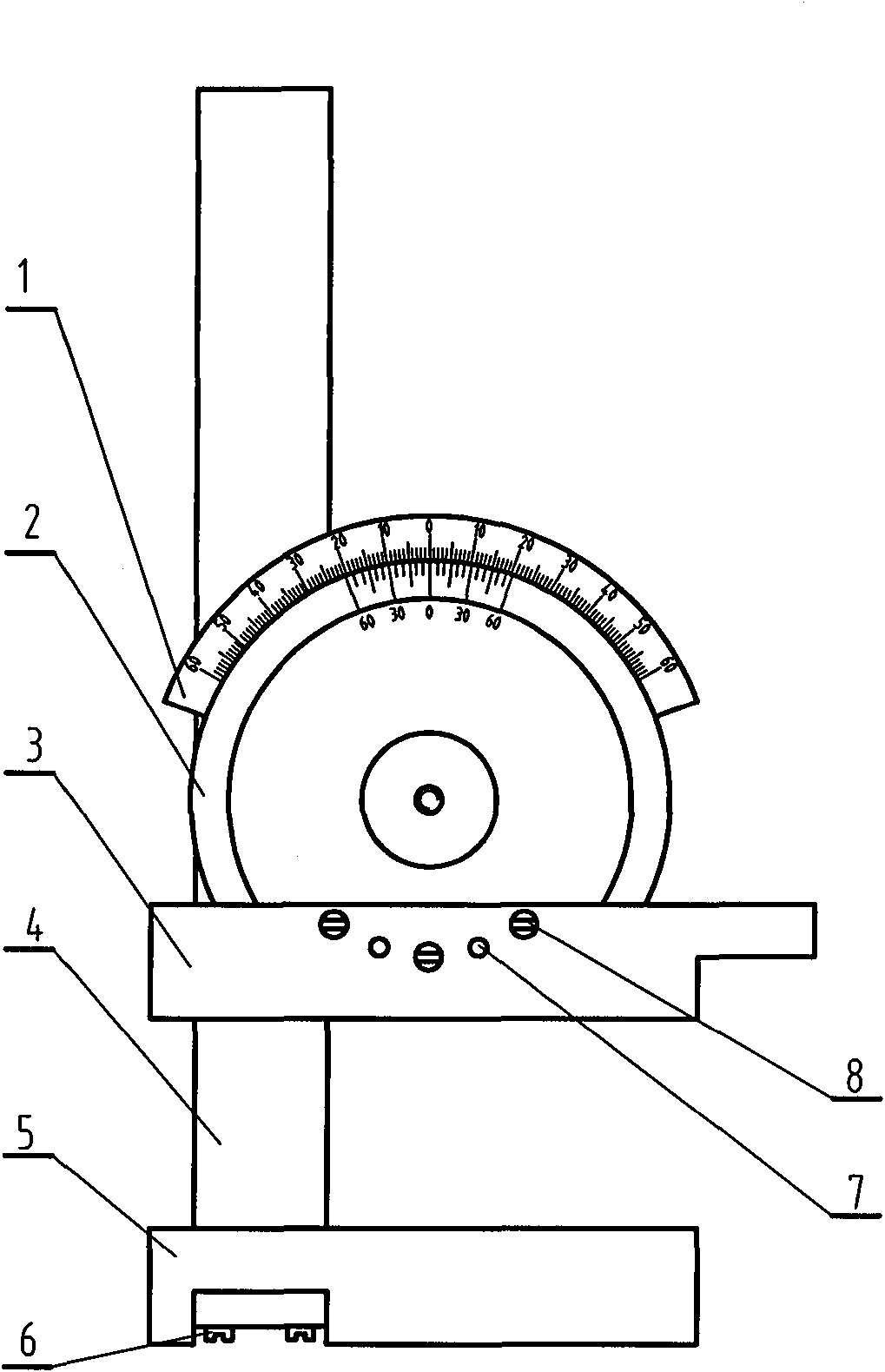

Special angle gauge for outer cone

A special volume, outer cone technology, used in angle/taper measurement, gauges for measuring angle/taper, measuring gauges, etc., can solve the problem of difficulty in ensuring the accuracy of the processed conical surface, trouble, etc., to achieve convenient measurement and measurement results. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

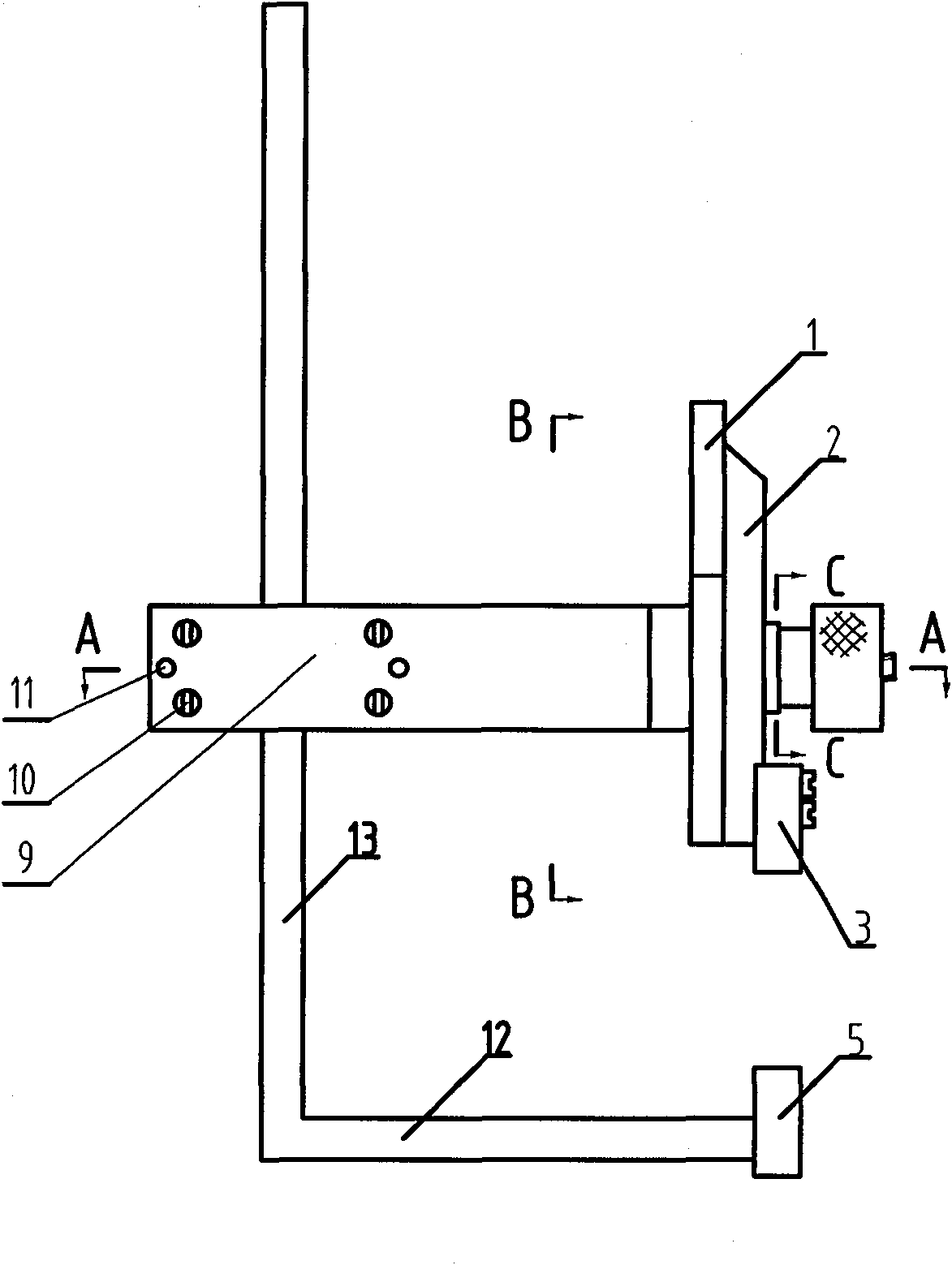

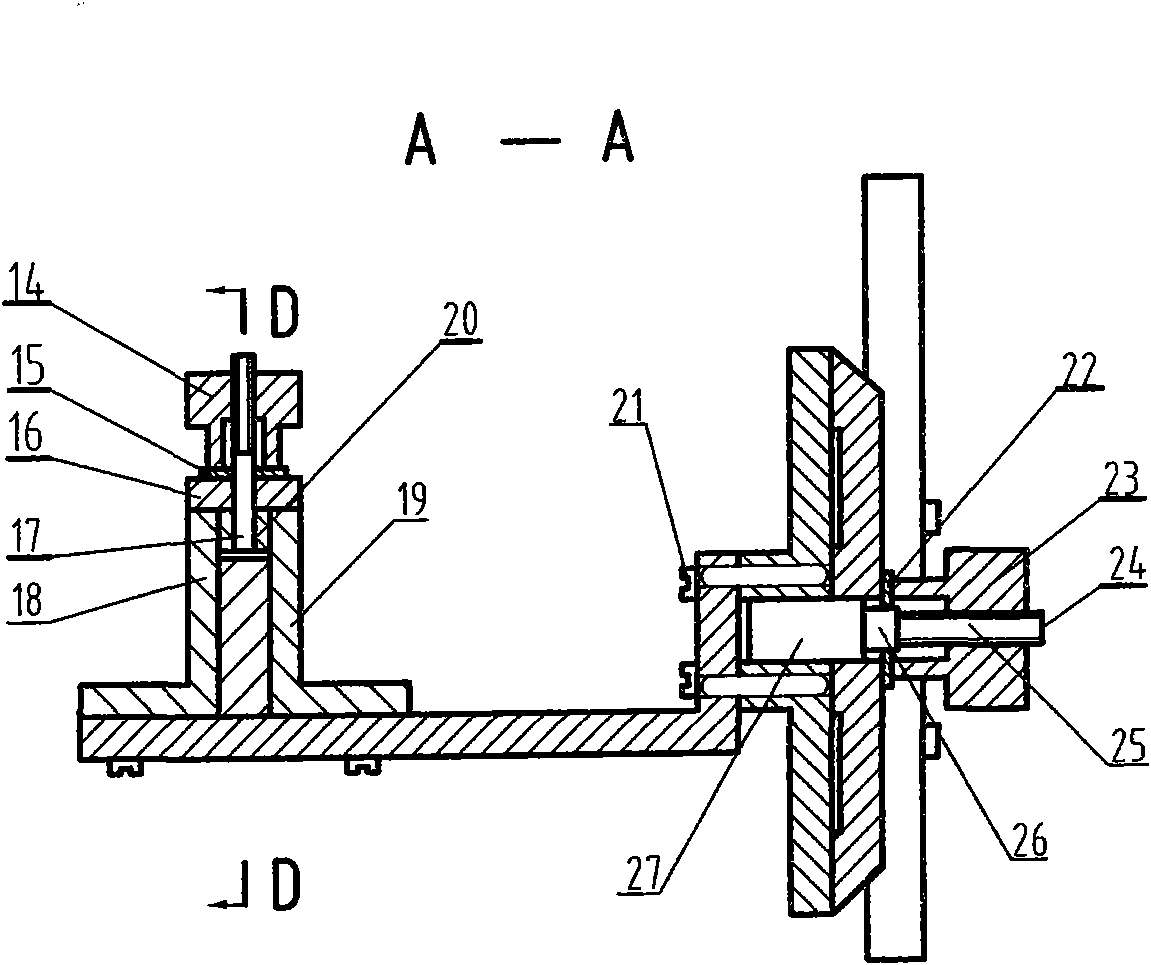

[0018] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0019] The guide bar 4 is L-shaped, connected by the cross bar 12 and the longitudinal bar 13 at an angle of 90°, one end of the cross bar 12 is equipped with a lower measuring ruler 5 through the first screw 6, and a guide block is set on the longitudinal bar 13 to guide The block is made up of left side plate 18, right side plate 19 and partition plate 20, left side plate 18 and right side plate 19 are L-shaped and arranged symmetrically, and partition plate 20 is installed between left side plate 18 and right side plate 19 , the upper plane of the partition plate 20 is flush with the upper planes of the left side plate 18 and the right side plate 19, and one end surface of the left side plate 18 and the right side plate 19 is connected to the connecting plate 9 through the third screw 10 and the third pin 11 Connect, the other end face that guide block and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com