A triangulation-based helical path generation method for high-speed NC milling of complex cavities

A CNC milling and triangulation technology, applied in the direction of program control, computer control, general control system, etc., to achieve the effect of improving kinematics characteristics and avoiding sudden changes in curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

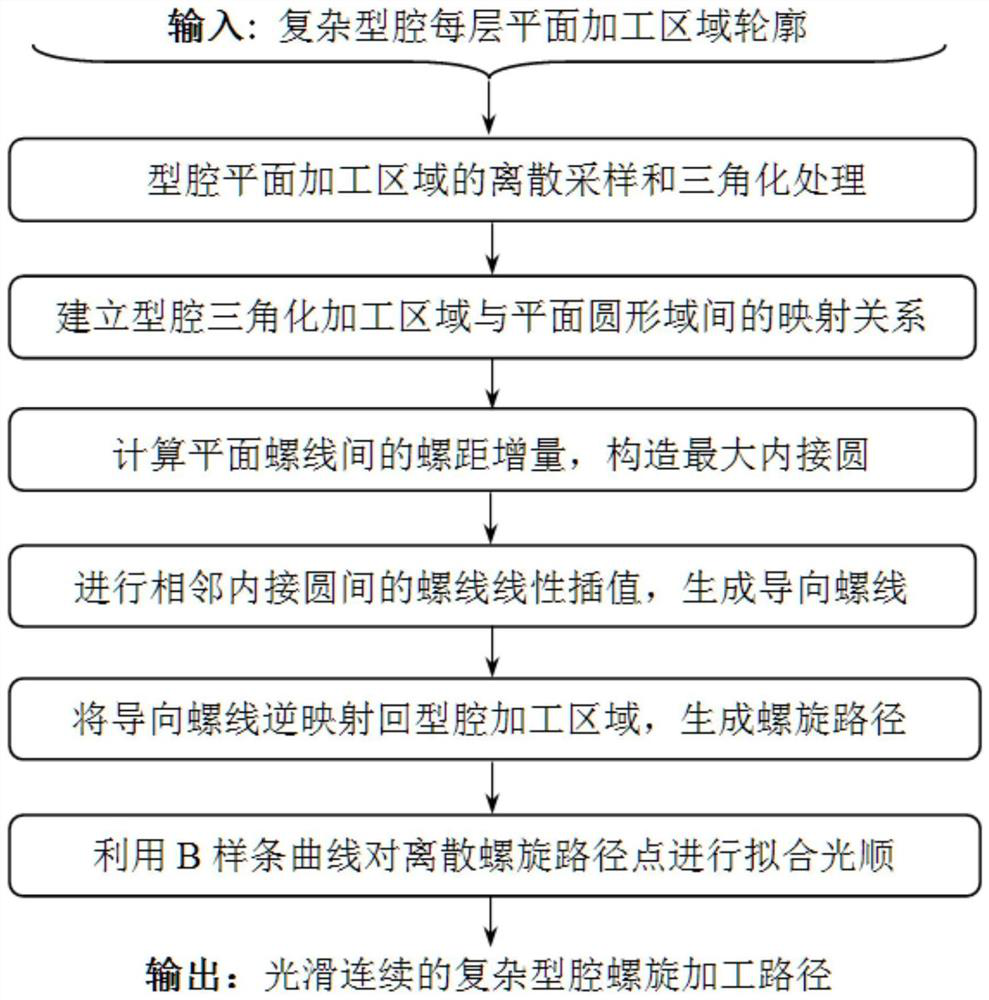

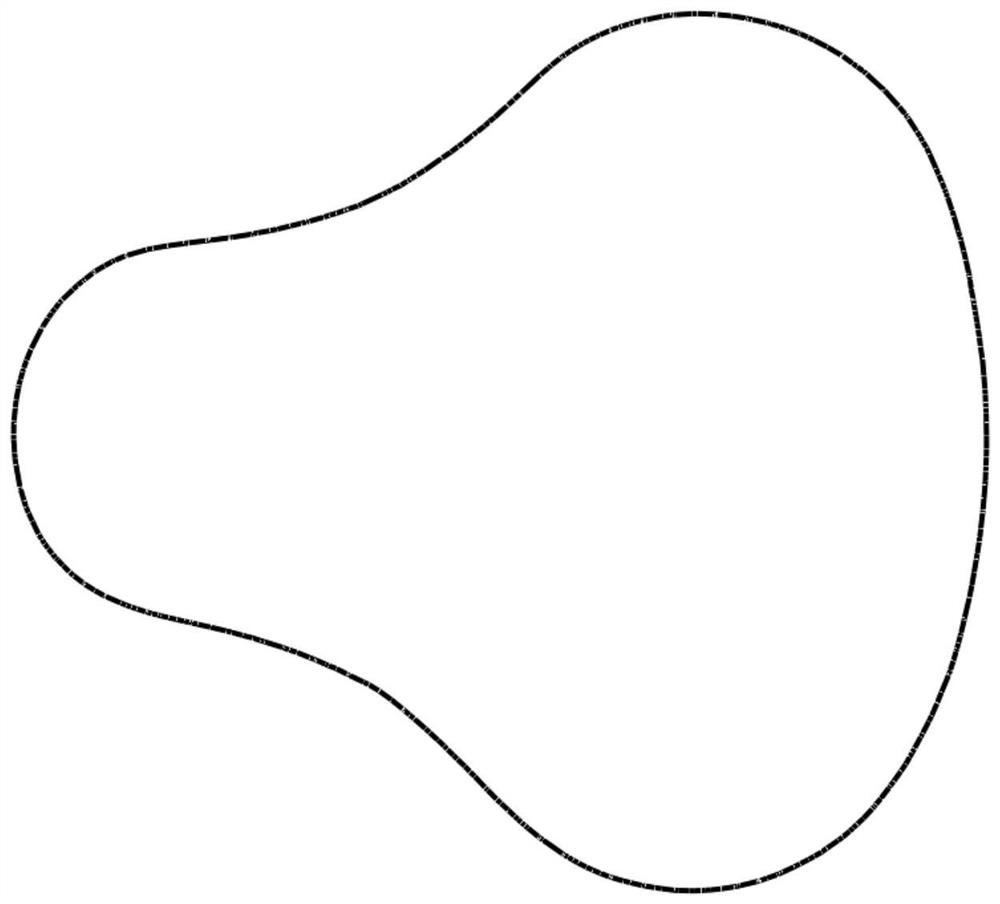

[0034] A flow chart of a method for generating a helical path for high-speed CNC milling of complex cavity based on triangulation of the present invention is as follows: figure 1 shown. Below, with figure 2 Taking the contour machining of the seat cavity as shown as an example, the specific implementation process of the present invention will be described in detail with reference to the accompanying drawings and implementation steps. The specific implementation process is as follows:

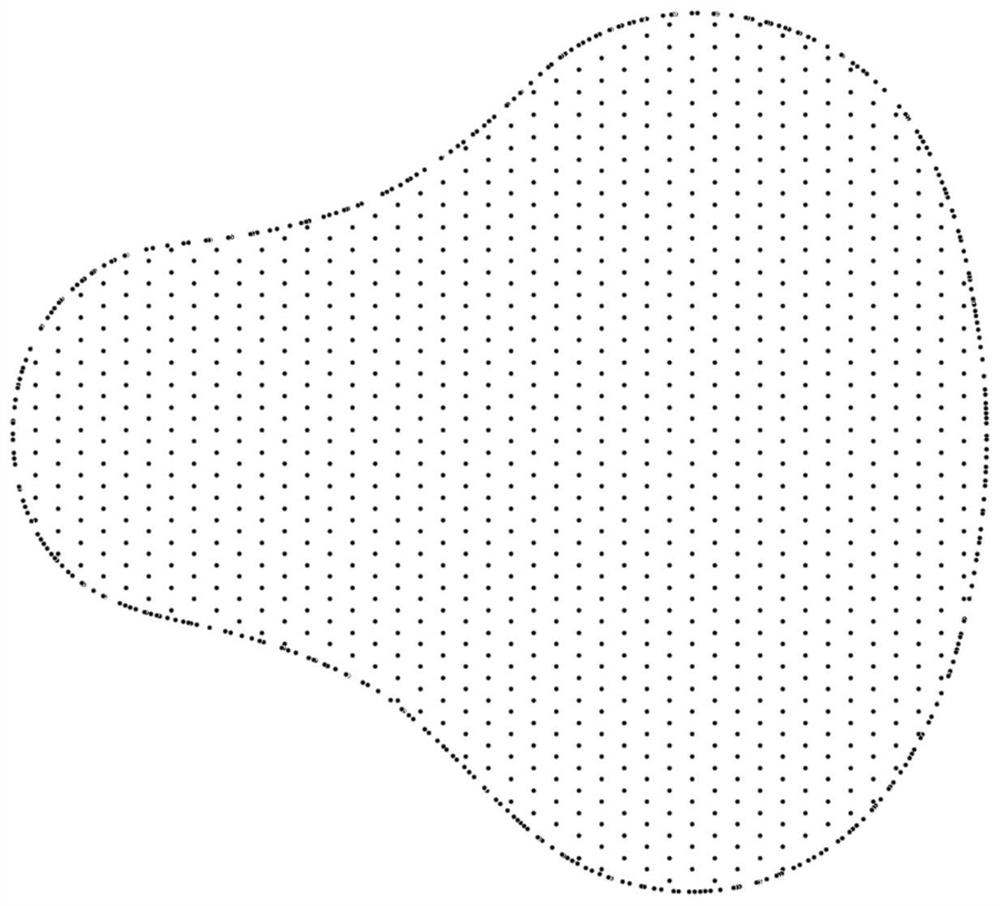

[0035] (a) Triangulation of the plane machining area of the cavity, the specific steps include:

[0036] a1. First determine the sampling interval in the x-direction and y-direction of the cavity plane machining area and Its calculation formula is as follows:

[0037]

[0038] In the formula, X b and Y b is the length of the plane bounding box of the cavity processing area in the x and y directions, int( ) is the rounding operation, L Δ is the side length of the mesh triangle, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com