Keyboard assembling and processing equipment

An assembly processing and keyboard technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of increasing labor force, reducing efficiency, wasting time, etc., and achieve the effect of reducing labor force, improving processing efficiency, and avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

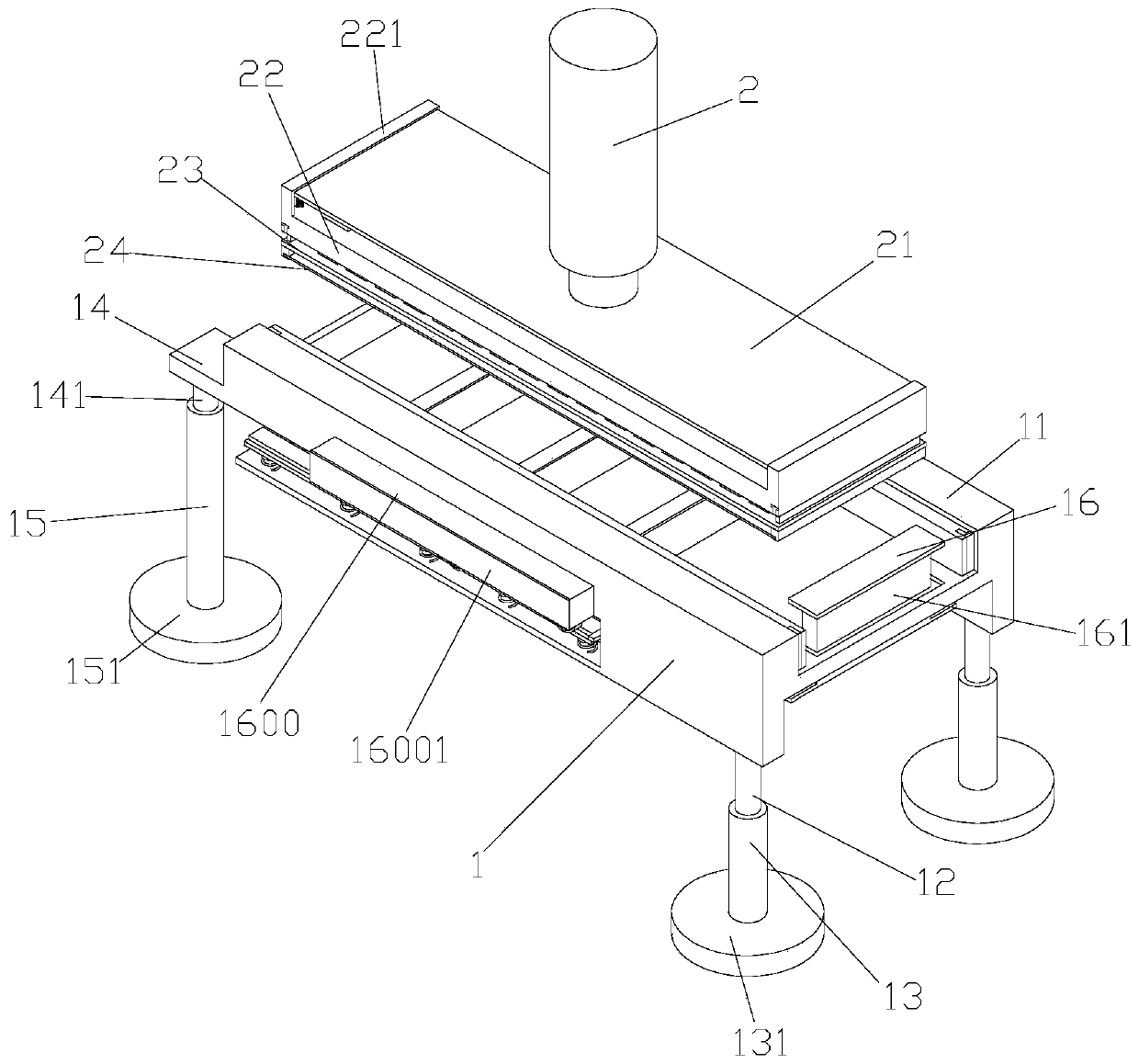

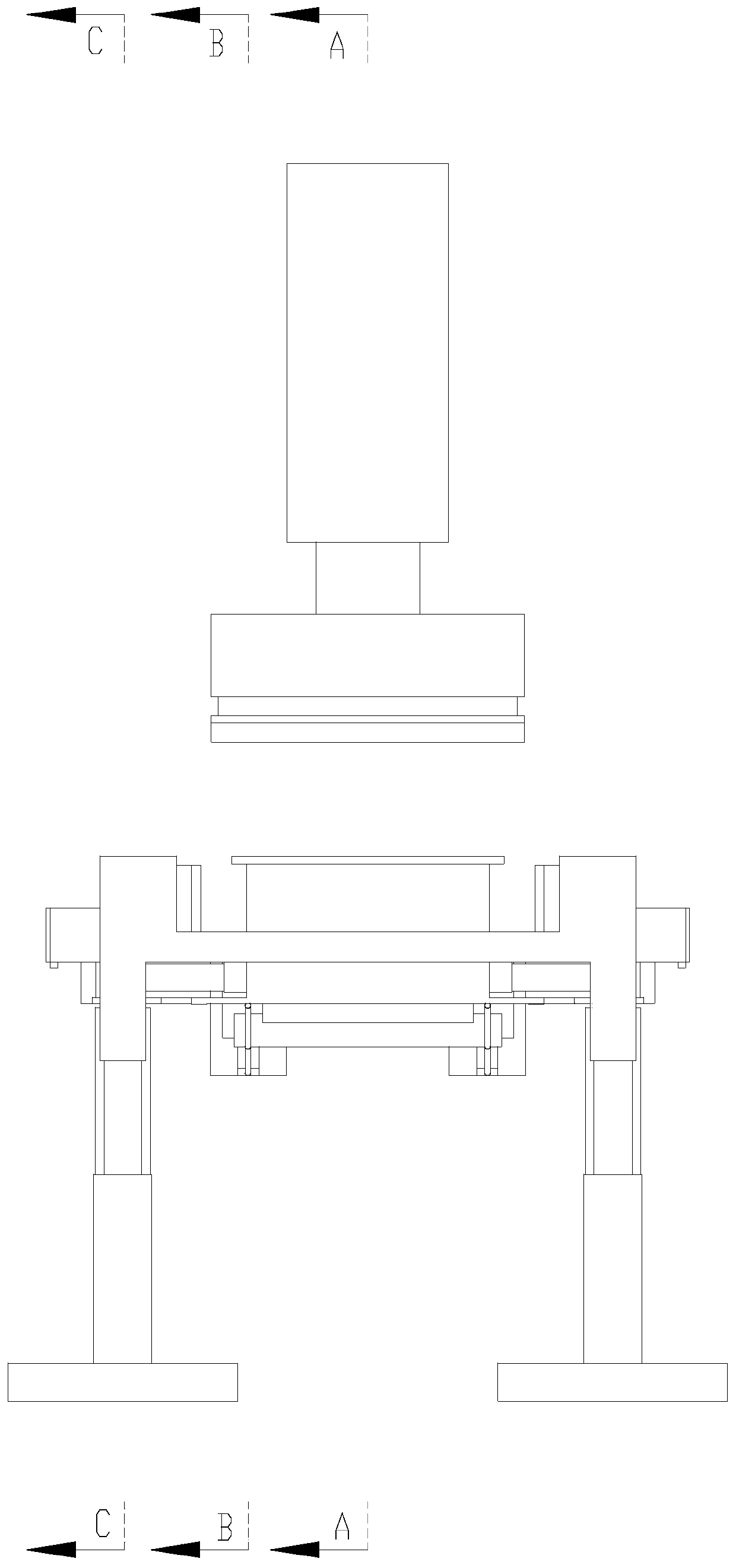

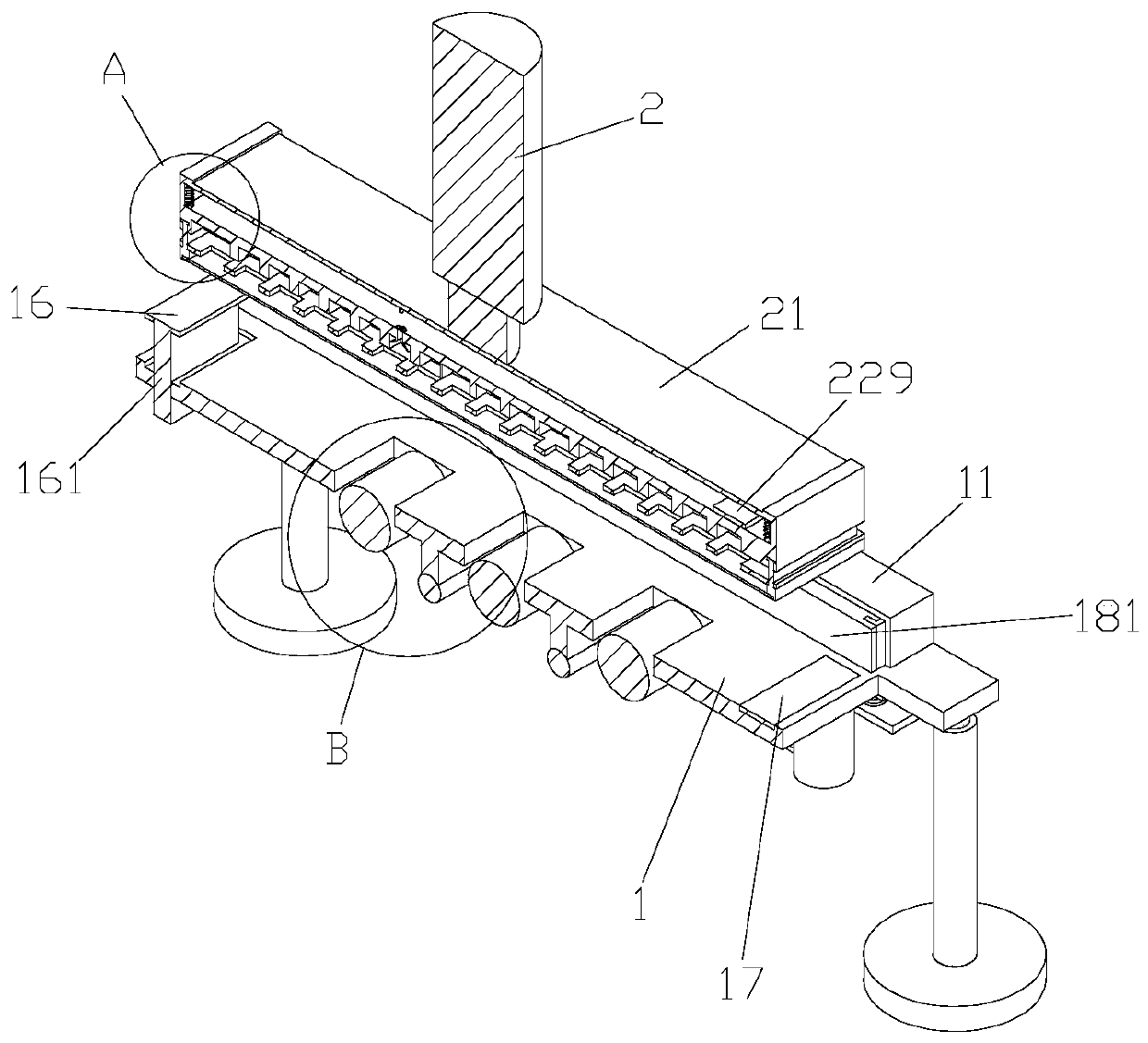

[0039] like Figure 1-23As shown, a keyboard assembly and processing equipment includes a processing table 1 and a hydraulic rod 2 arranged above the processing table 1. First baffles 11 are arranged on both sides of the processing table 1, and the piston rod of the hydraulic rod 2 A first loading plate 22 is provided on the top, and a plurality of first installation grooves 226 are provided at the bottom of the first loading plate 22. A first connecting plate 14 is provided on the side wall of the processing table 1, and the first connecting plate 14 is provided on the side wall of the processing table 1. The bottom of the plate 14 is provided with a first support rod 141, the bottom of the processing table 1 is provided with a second support rod 12, the processing table 1 is provided with a second baffle 161, and the first baffle 11 is provided with a The first movable chamber 111, the first movable chamber 111 is provided with a connecting spring 182, and one end of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com