eps foam material forming device and process

A foam material and molding device technology, applied in the field of EPS foam material, to achieve the effect of high-efficiency antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

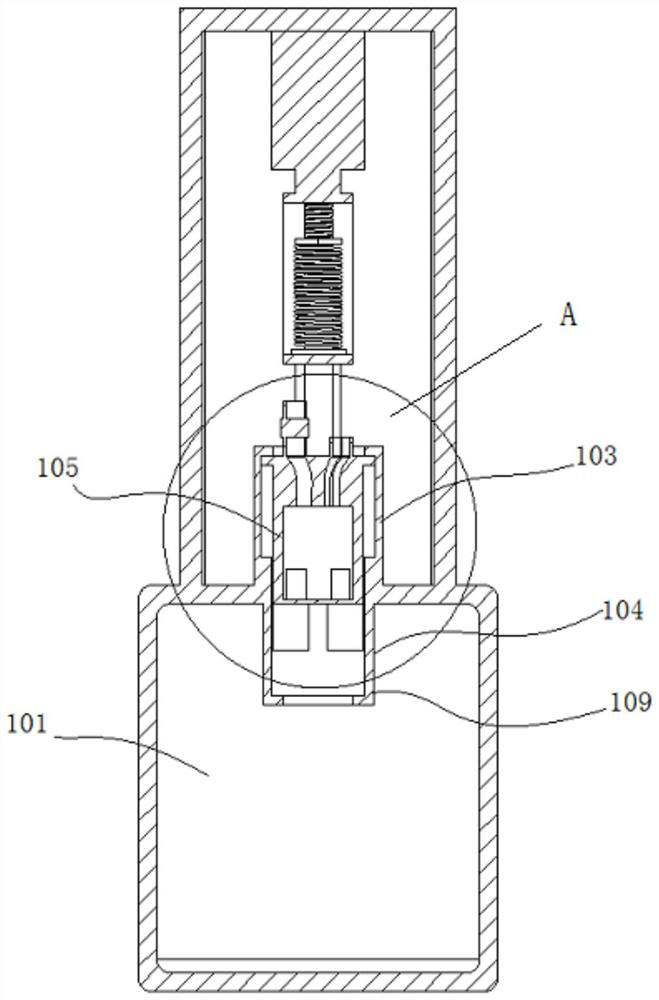

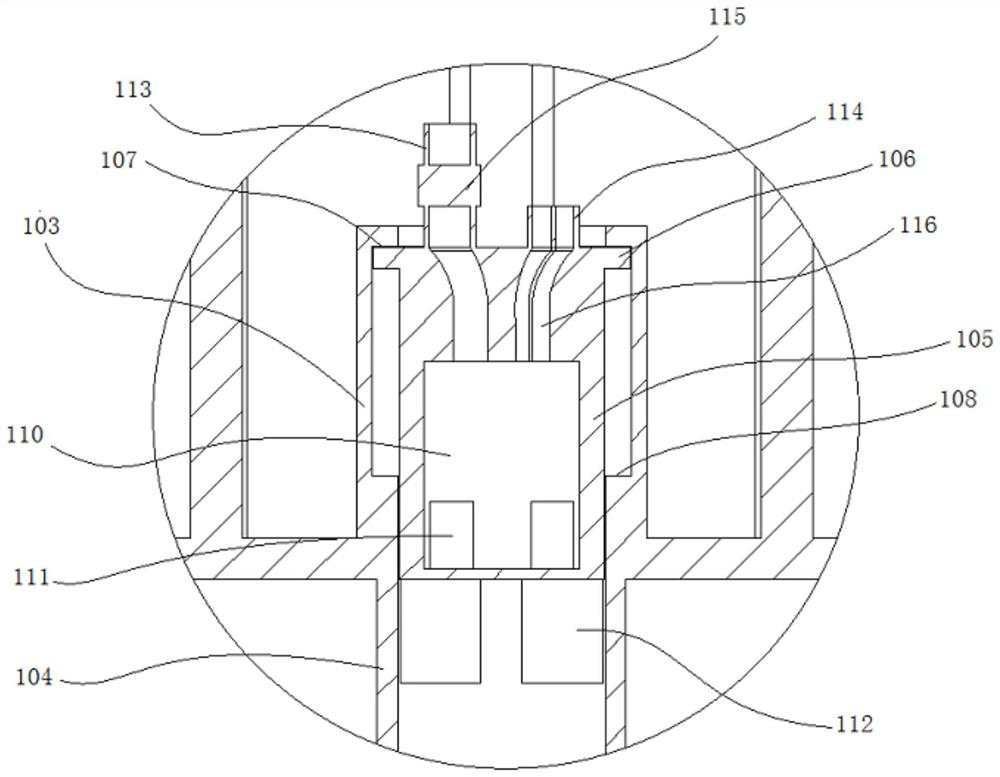

[0036] EPS foam molding device, such as Figure 1-Figure 7As shown, it includes a material reaction device, and the material reaction device includes a reaction housing 102 with a reaction chamber 101 inside. The middle part of the outer surface of the upper top plate of the reaction housing 102 is fixed with a bottom that communicates with the inside of the reaction chamber 101, and the upper end is open. The first cylindrical connection seat 103, the middle part of the inner surface of the upper top plate of the reaction housing 102 is fixed with the first connection seat 103 opposite to the first connection seat 103 and the upper and lower ends are open cylindrical second connection seat 104, also includes a sliding column 105 arranged in the first connecting seat 103 and can slide down to the second connecting seat 104 along the inner wall of the first connecting seat 103, the upper end of the sliding column 105 is located on the outer side wall of the sliding column 105 A...

Embodiment 2

[0050] EPS foam forming process is characterized in that it adopts the EPS foam forming device in embodiment 1, which comprises the following steps:

[0051] Step 1, polystyrene resin is carried out pretreatment, specifically comprises the following steps:

[0052] Step 1 put polystyrene resin into the reaction chamber 101 of the material reaction device, pass CO2 into the reaction chamber 101 of the material reaction device through the CO2 inlet passage 116 of the air inlet pipe 114 and feed into the reaction chamber 101 through the feed pipe 113 Adding an antistatic agent, wherein the antistatic agent is dodecyl dihydroxypropyl methyl ammonium sulfate, to obtain modified EPS beads;

[0053] Step 2 Add titanate and calcium carbonate powder into a high-mixer at a mass ratio of 1:3 for mixing, keep warm at 100-120°C for 1-2h, then add neodymium oxide, and stir at 80-90°C for 0.5-1h , to obtain a mixed solution; the mixed solution contains calcium carbonate, which can improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com