Dry sphaghnum fiber scattering equipment

A dry sphagnum and fiber technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high labor cost, laborious labor, etc., and achieve the effects of reduced labor cost, simple structural design, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with the embodiments, but the content of the present invention is not limited to the following embodiments.

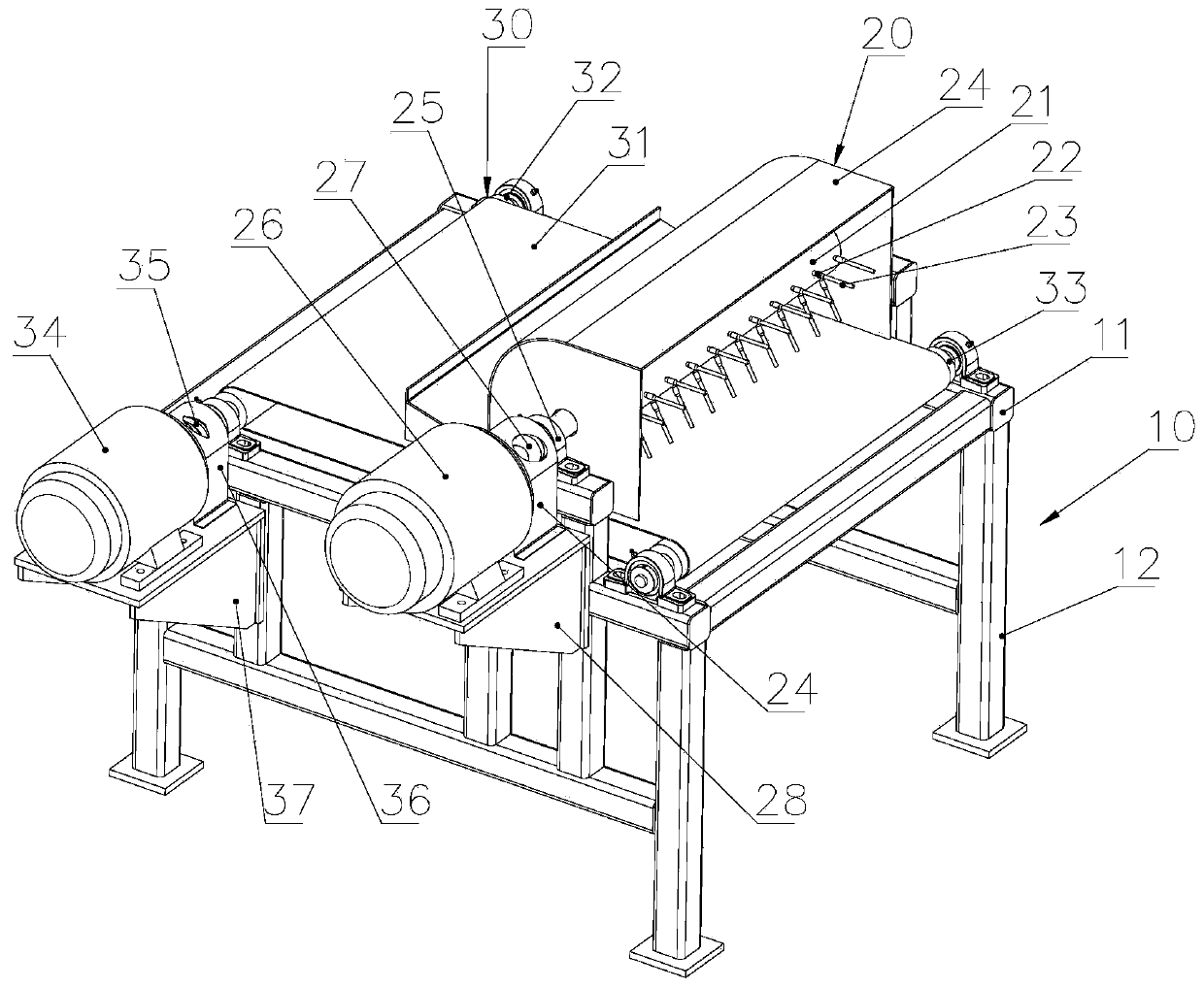

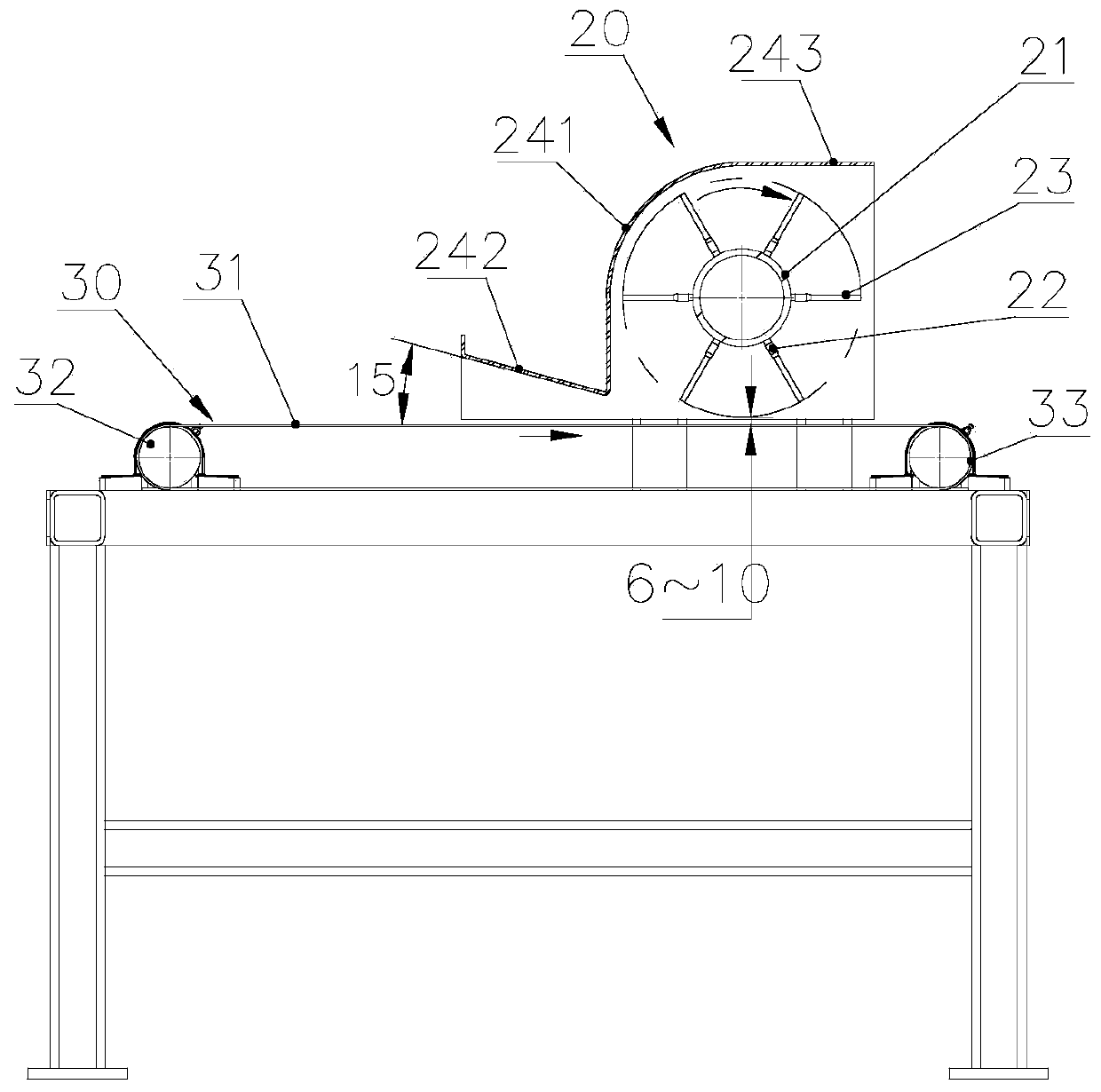

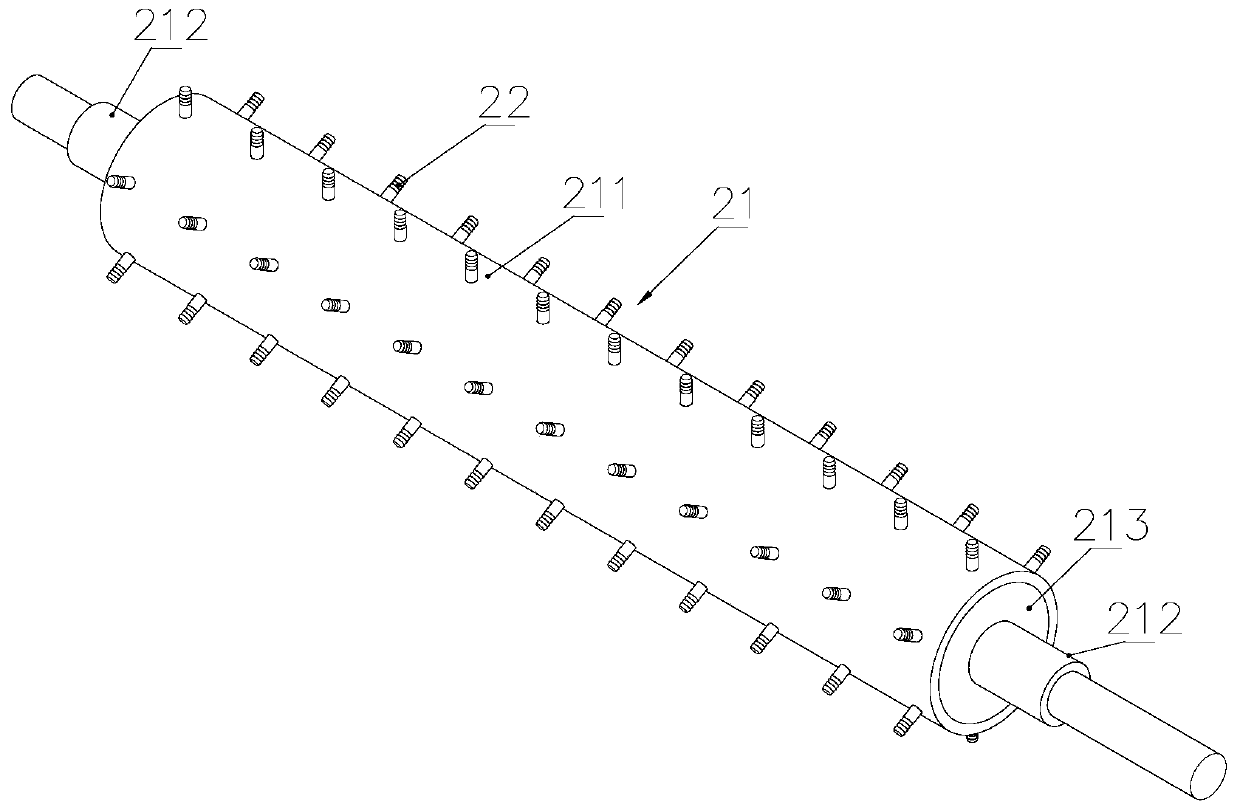

[0029] Refer to Figure 1 ~ Figure 6 This embodiment provides a dry sphagnum fiber dispersing equipment, including a frame 10, a dispersing device 20 installed on the frame 10, and a flat belt conveyor 30. The flat belt conveyor 30 is set on the top of the frame 10 and includes a horizontally running flat belt 31; the dispersing device 20 is mainly composed of a roller motor 26, a dispersing roller 21, a roller cover 24 and a number of silicone hoses 23 The dispersing roller includes a cylindrical hollow roller 211. The two ends 211 of the hollow roller are closed by shaft heads. The outer circumferential surface of the hollow roller 211 is radially provided with a number of pagoda shafts 22 arranged at intervals. Silicone hoses ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com