Machine-made sand equipment with large particle secondary processing function

A secondary processing and machine-made sand technology, which is applied in grain processing and other fields, can solve the problems of cumbersome process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

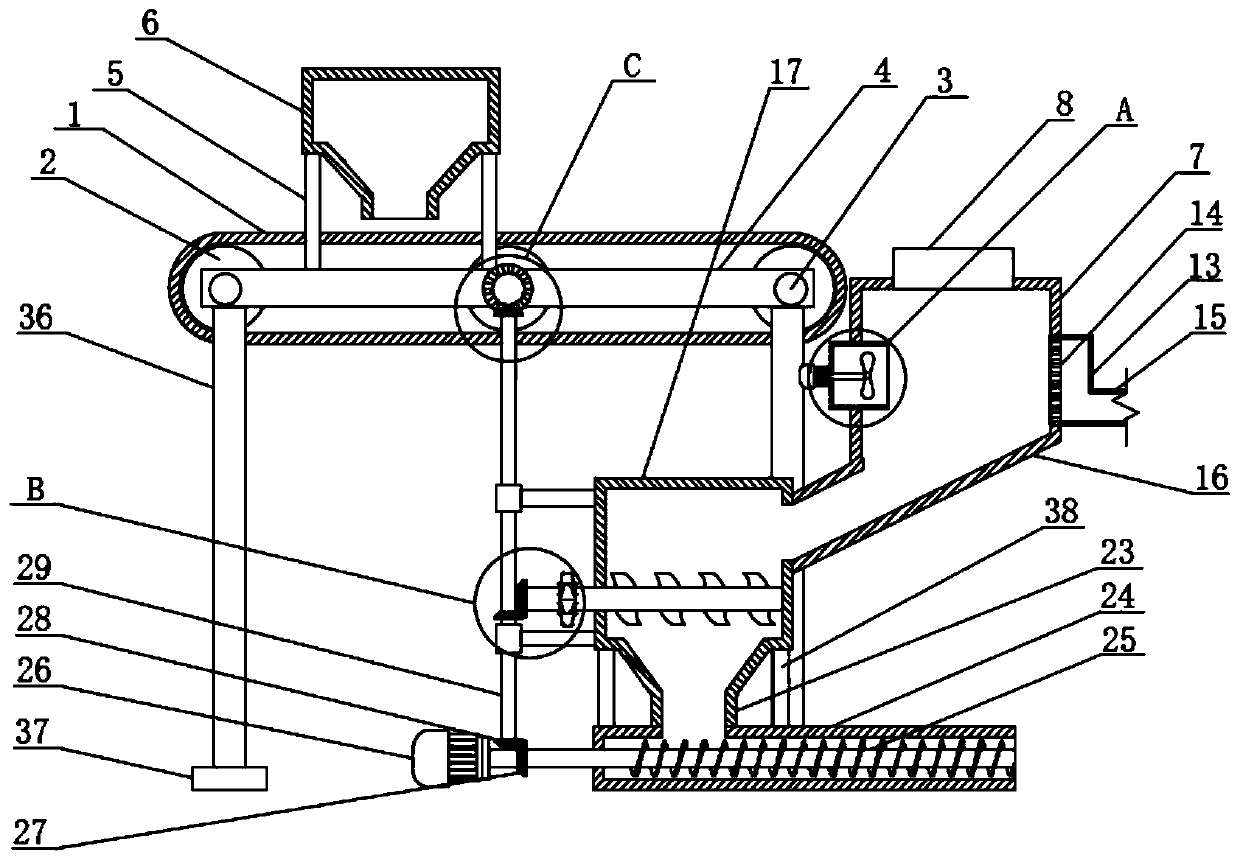

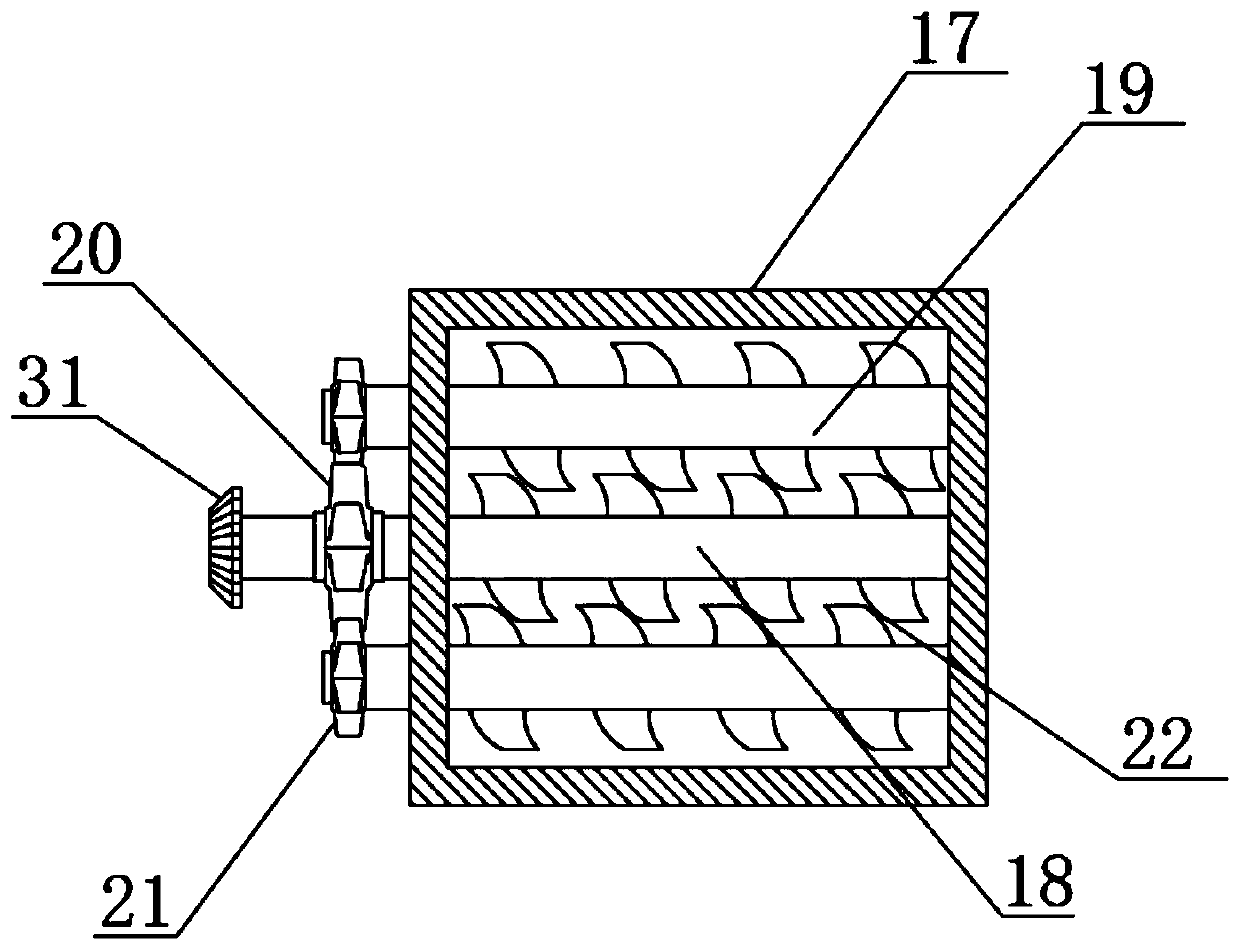

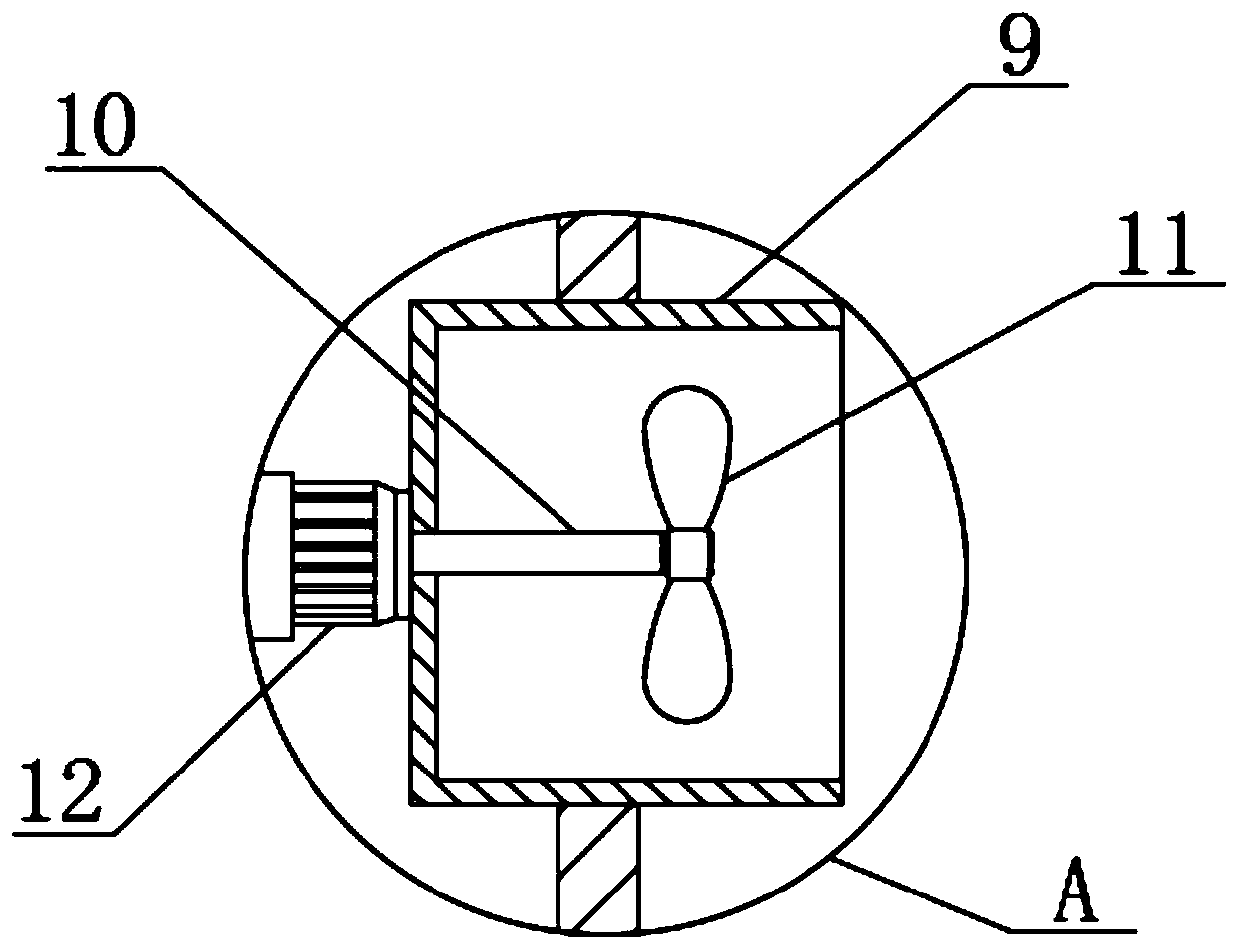

[0026] refer to Figure 1-5 , a kind of machine-made sand equipment with large particle secondary processing, including a conveyor belt 1, a plurality of rollers 2 are arranged in the conveyor belt 1, a central shaft 3 is fixedly sleeved in the plurality of rollers 2, and the center shaft 3 One end of the same side of multiple central shafts 3 is rotatably connected to the same beam 4, the two beams 4 are fixedly connected to the first strut 5, and the top ends of the four first struts 5 are fixedly connected to each other. There is the same vibrating feeder 6, a screening box 7 is fixedly arranged under one end of the conveyor belt 1, a feed inlet 8 is provided on the top of the screening box 7, and a bellows 9 is fixedly connected to the inner wall of one side of the screening box 7. The bellows 9 and The screening boxes 7 are connected to each other, and a first roller shaft 10 is rotatably connected to one side of the bellows 9. One end of the first roller shaft 10 is fixe...

Embodiment 2

[0036] refer to Figure 1-5 , a kind of machine-made sand equipment with large particle secondary processing, including a conveyor belt 1, a plurality of rollers 2 are arranged in the conveyor belt 1, a central shaft 3 is fixedly sleeved in the plurality of rollers 2, and the center shaft 3 They are connected by a belt drive, and one end of the same side of multiple central shafts 3 is rotatably connected to the same beam 4, and the first struts 5 are fixedly welded on the two beams 4, and the top ends of the four first struts 5 are fixedly welded. There is the same vibrating feeder 6, a screening box 7 is fixedly arranged under one end of the conveyor belt 1, a feed inlet 8 is provided on the top of the screening box 7, and a bellows 9 is fixedly welded on the inner wall of one side of the screening box 7, and the bellows 9 and The screening boxes 7 are connected to each other, and a first roller shaft 10 is rotatably connected to one side of the bellows 9. One end of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com