Snail washing device for processing of rice noodles with snails

A cleaning device and technology for snail powder, applied in the field of cleaning devices and snail cleaning devices for snail powder processing, can solve problems affecting the processing process, residual stains, poor cleaning effect, etc., and achieve the effect of simple structure and convenient centralized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

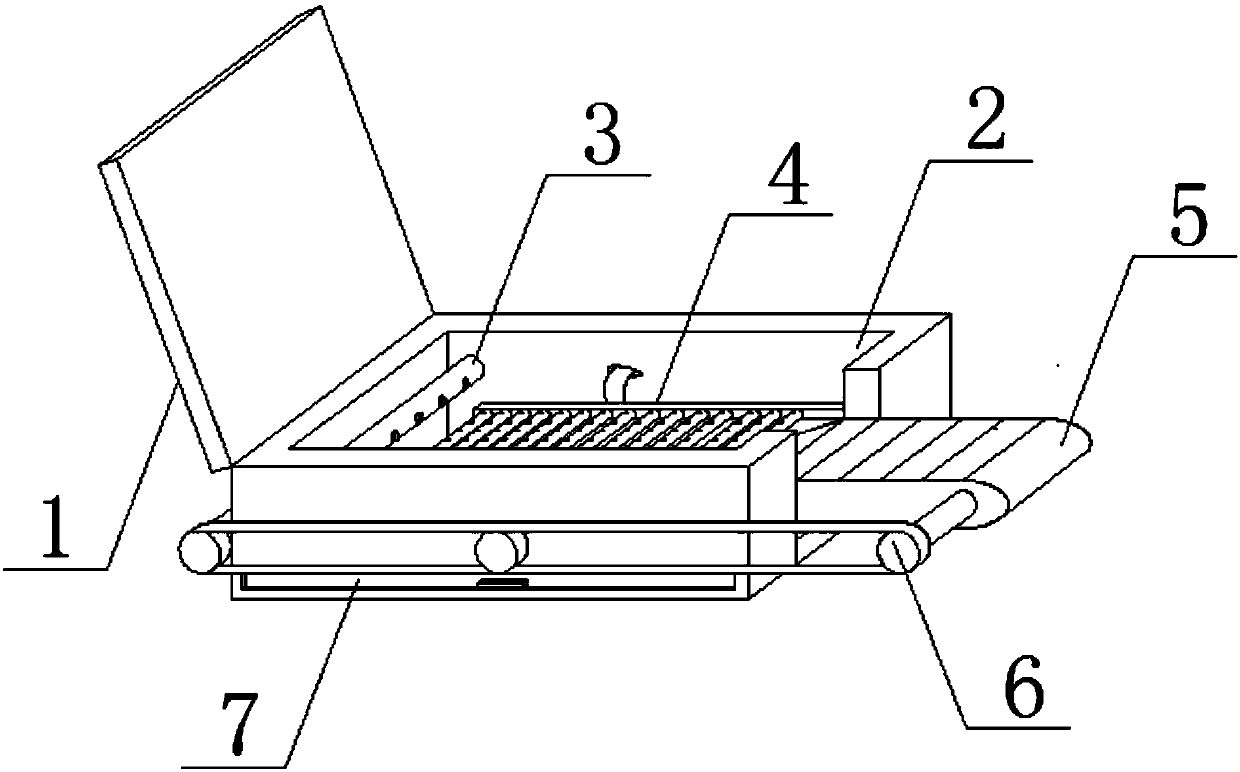

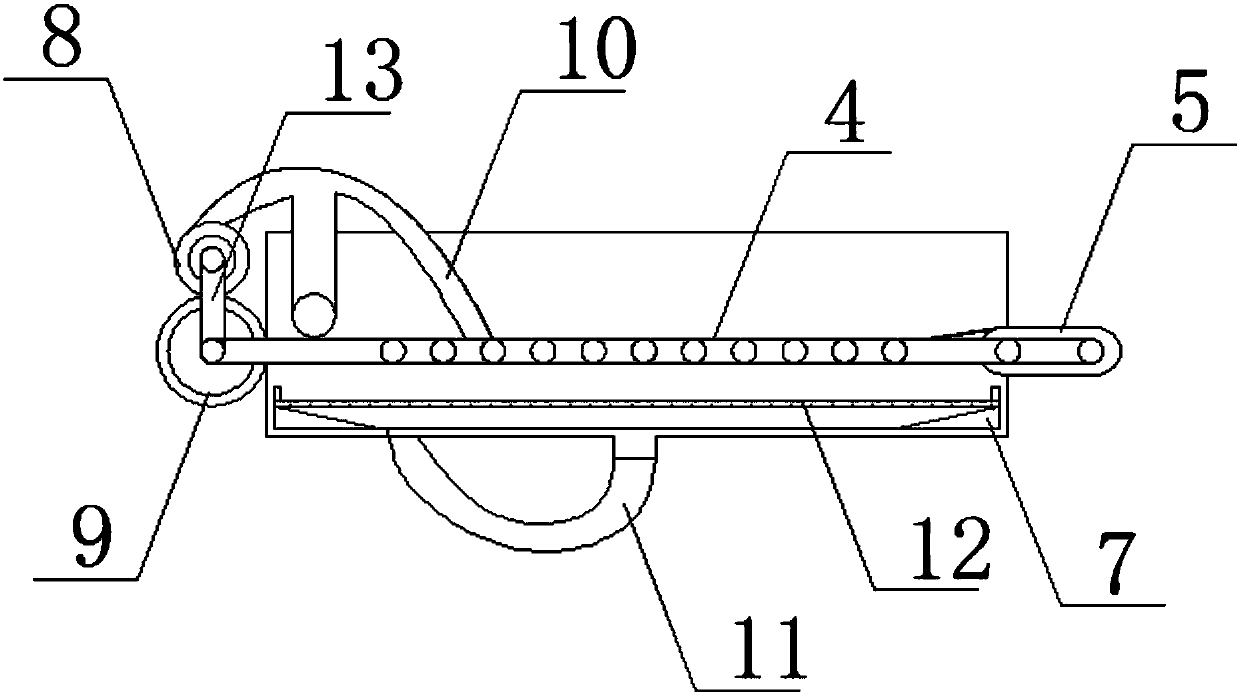

[0023] see Figure 1-3 As shown, a snail cleaning device for snail powder processing includes a sealing cover 1, a cleaning box 2 and a conveyor belt 5, and the sealing cover 1 is installed above the cleaning box 2, which can seal the cleaning box 2 and prevent water from running around during the cleaning process. Splash, and cleaning box 2 sides are equipped with conveyer belt 5, can clean and be pushed to the snail of conveyer belt 5 one ends and send out so that collect, conveyer belt 5 one sides connect motor 9 by first pulley 6, external power supply, can To provide power for multiple devices connected to the motor 9, the top of the motor 9 is connected to the circulation pump 8 through the second pulley 13, and the filtered water without waste residue can be recycled, effectively saving water resources, and the circulation pump 8 One end is connected to the rolling device 4 through the water inlet pipe 10, and the snail noodles can be pushed from one end to the other, a...

Embodiment 2

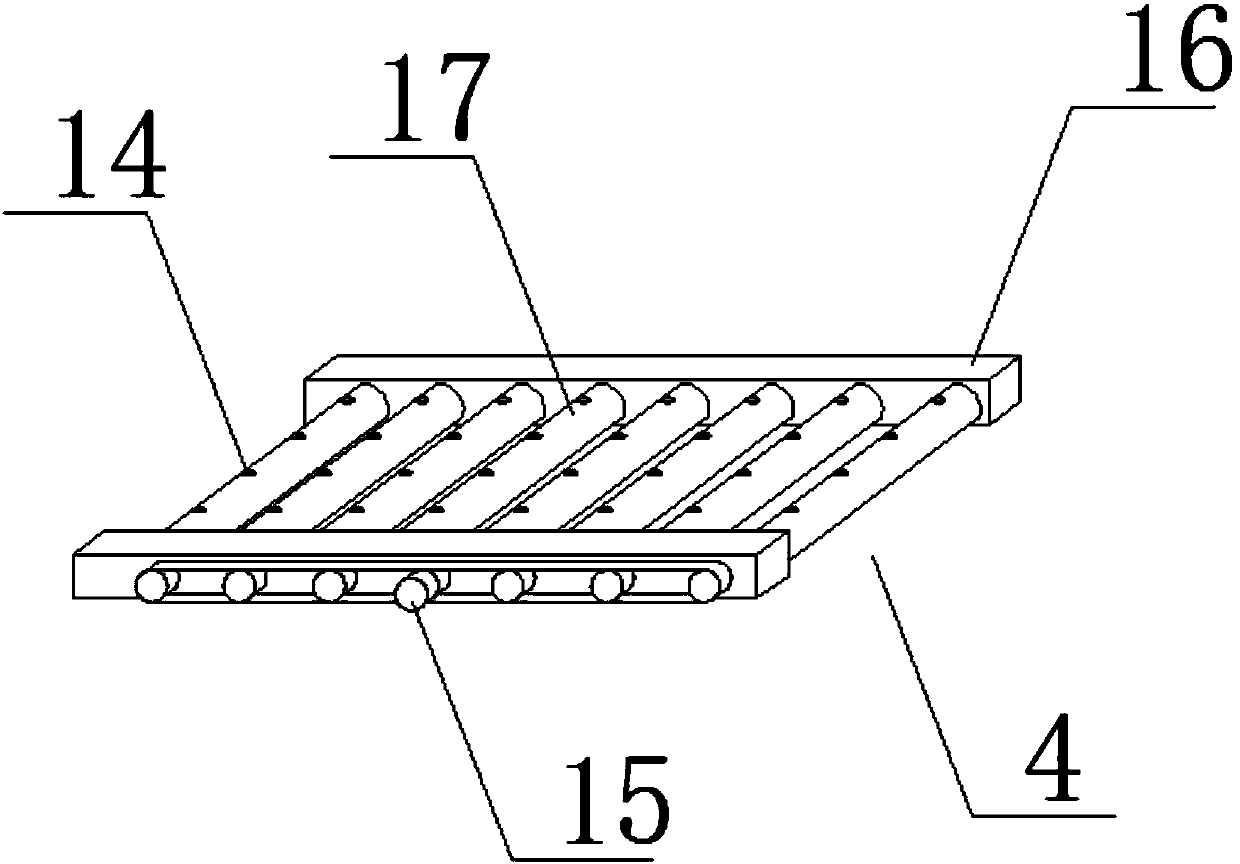

[0025] read on Figure 1-3 As shown, the difference with Embodiment 1 is that one end of the tail end pipe 3 is connected to the water inlet pipe 10, and the tail end pipe 3 is provided with several water spray ports 17 with openings to the lower right, and the tail end pipe 3 is supplied with water by the water inlet pipe 10. And spray water to the lower right, which can help push the snails forward and help clean the snails.

[0026] One end of the conveyor belt 5 is connected to the rolling device 4 through an inclined plate-mounted structure, and the longitudinal height of the rolling device 4 is smaller than the longitudinal height of the conveyor belt 5, so that the cleaning water will not flow out from the conveyor belt 5, and due to the setting of the inclined plate, this kind of The design does not interfere with the normal expulsion process of the snails.

[0027] The bottom of the waste residue box 7 is an inverted circular platform structure, and the outlet pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com