Off-line assembling device for multi-roll-core lithium battery

A technology for assembling devices and lithium batteries, which is applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve problems such as inconvenience in battery assembly, and achieve the effects of simple structure, high precision and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

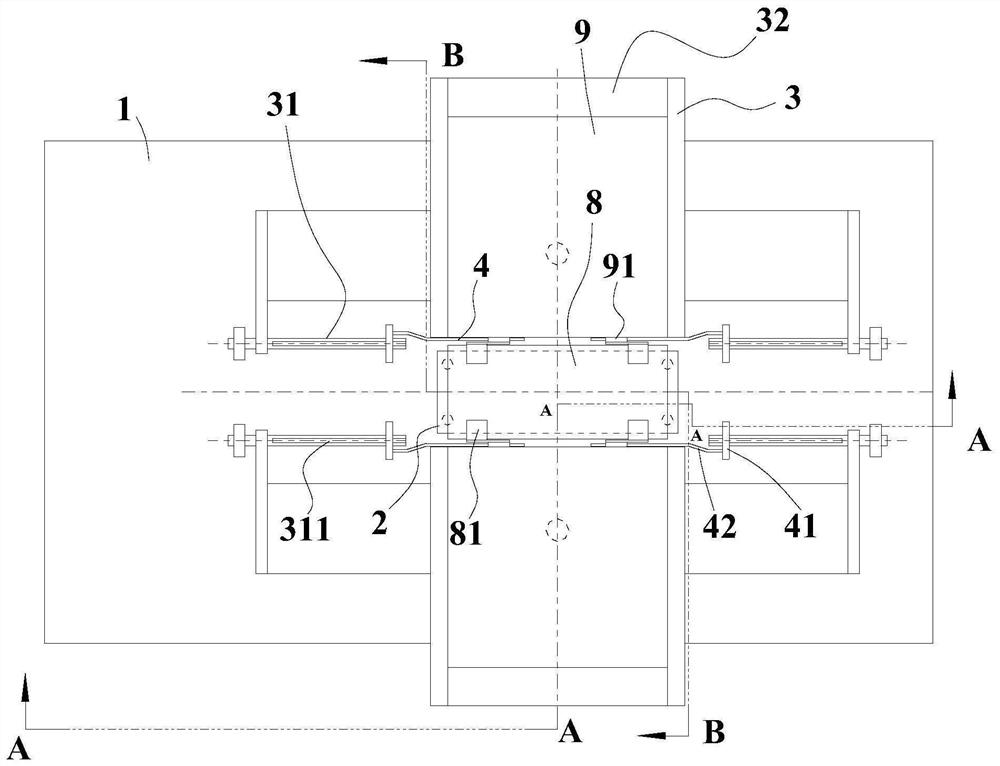

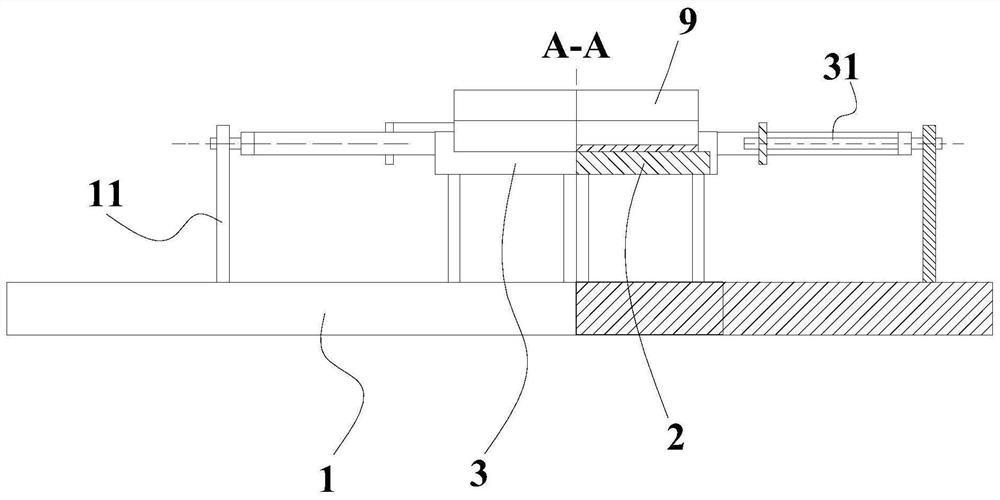

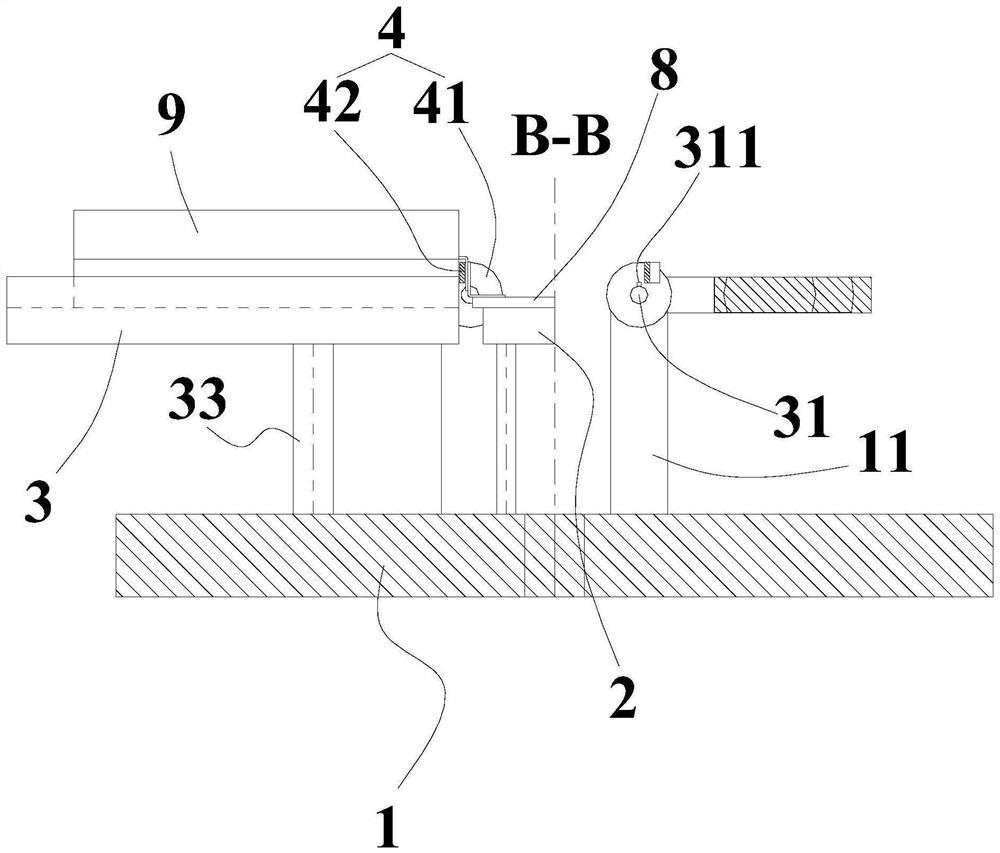

[0059] Such as figure 1 As shown, an off-line assembly device for a multi-roll core lithium battery includes a bracket 1 , a cover support plate 2 , a composite core plate 3 , and a folding knife 4 .

[0060] In this embodiment, the main function of the bracket 1 is to provide installation positions for the rest of the components. The bracket 1 is not limited to a specific shape, as long as it can meet the requirements of installing and matching the various components, and realize the corresponding functions. The bracket 1 in the embodiment is a rectangular plate.

[0061] For ease of description and understanding, the figure 1 The angle of view is the angle of view of the top view, and the rest of the orientations are based on this. It should be understood that this orientation setting is only for the convenience of description and understanding, and should not be construed as a limitation of the present invention.

[0062] Such as figure 1 , 3 As shown, a cover plate sup...

Embodiment 2

[0074] The difference between this embodiment and Embodiment 1 is:

[0075] Such as Figure 4 As shown, it also includes a shifting block 5 slidably installed on the bracket 1, and the sliding direction of the shifting block 5 is parallel to the sliding direction of the sliding block 41; that is, the sliding direction of the shifting block 5 is along the left and right directions.

[0076] Such as Figure 4 As shown, the shift block 5 is provided with a shift fork 51 with an opening facing the slider 41 , and the slider 41 is located in the opening of the shift fork 51 ; the bracket 1 is provided with a shift block driving mechanism 6 .

[0077] Such as Figure 4 , 5 As shown, two shifting blocks 5 are provided, and the two shifting blocks 5 are respectively located between the rotating shafts 31 at the same end of the two composite core boards 3. Specifically, two pairs of shafts along the left and right sides are arranged between the rotating shafts 31 on the front and re...

Embodiment 3

[0082] The difference between this embodiment and embodiment two is:

[0083] Such as Figure 7-9 As shown, the rotating shaft 31 is provided with the same gear 312 , and the corresponding gears 312 of the two core plates 3 mesh with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com