Manipulator clamp for polishing inner wall of pot and inner wall of pot handle

A technology for manipulators and pot handles, applied in the field of grinding fixtures, can solve the problems of poor positioning, inconsistent quality of pots, and increased production costs, and achieve the effect of ensuring accuracy and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

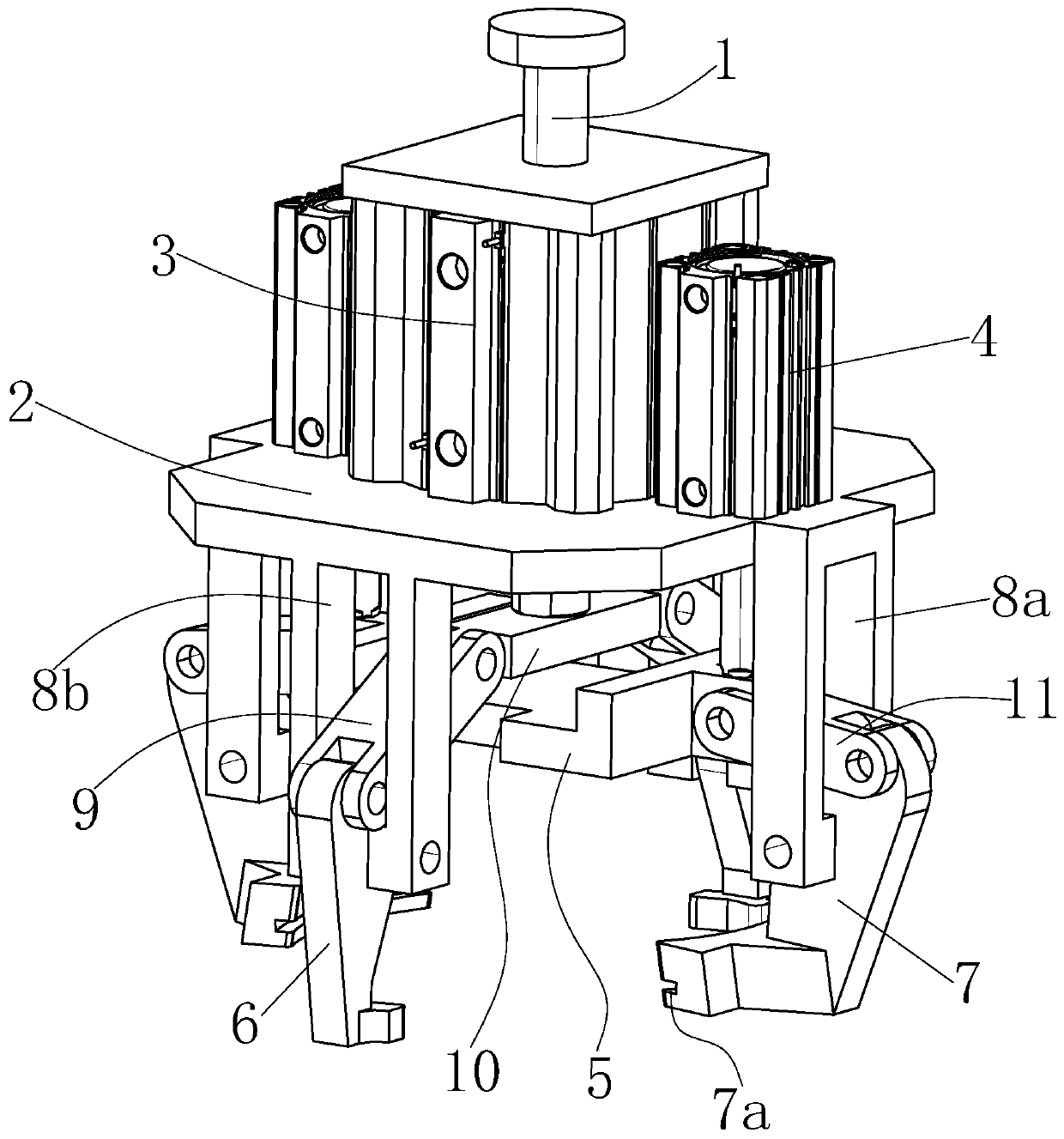

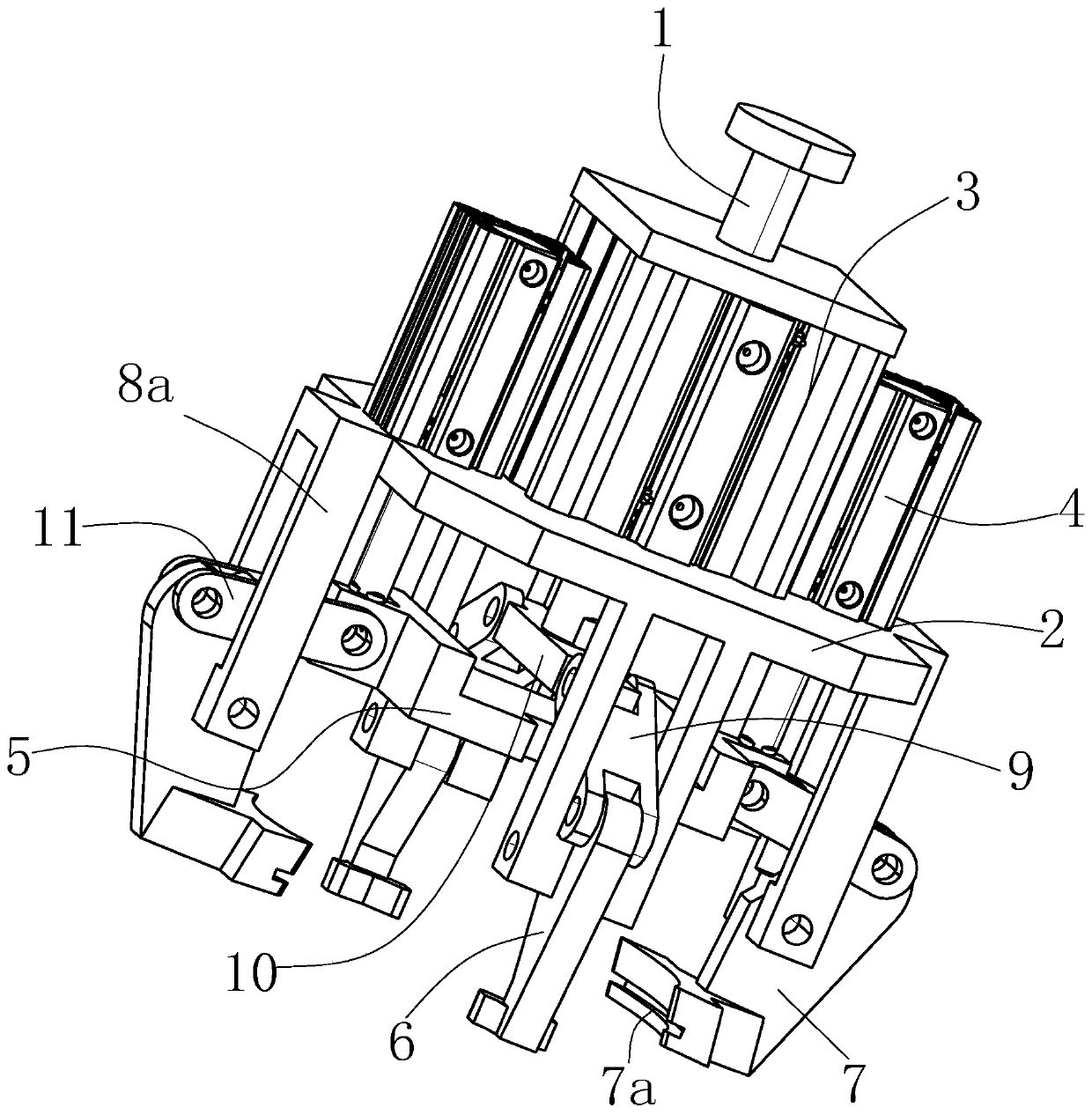

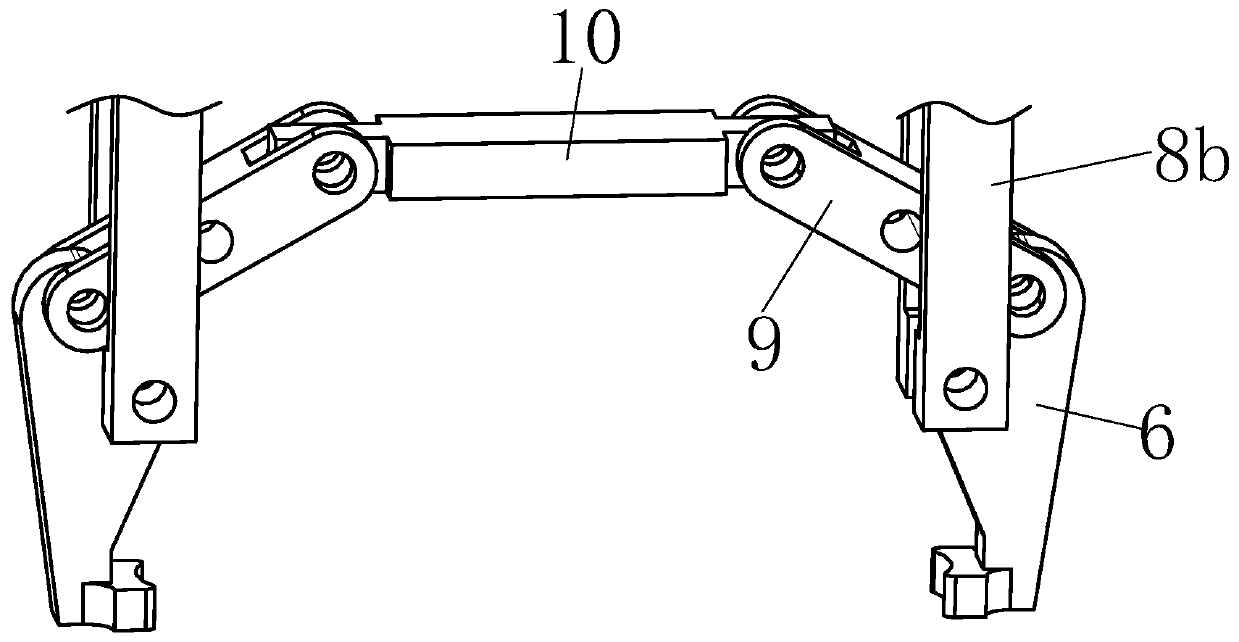

[0026] Such as Figure 1 to Figure 4 As shown, a manipulator fixture for polishing the inner wall of the pot and the inner wall of the handle of the pot, including:

[0027] The manipulator mounting flange 1 is used to connect with the manipulator;

[0028] The fixture main bearing mounting plate 2 is connected with the manipulator mounting flange 1;

[0029] A first driving source and a second driving source, the first driving source and the second driving source are correspondingly arranged on the fixture main bearing mounting plate 2;

[0030] The profile-shaped grippers 7 of the pot used in pairs are driven by the first driving source to clamp the shape of the mouth of the pot to realize self-centering positioning of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap