A cutting and printing integrated device

An integrated printing technology, applied in dough forming and cutting equipment, dough embossing machine, metal processing, etc., can solve the problems of low production efficiency, increased input costs, and increased production costs, so as to improve processing efficiency and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below.

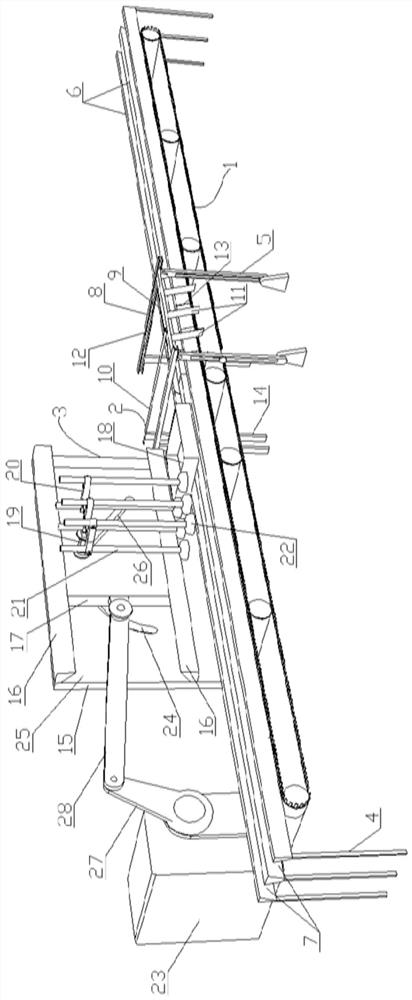

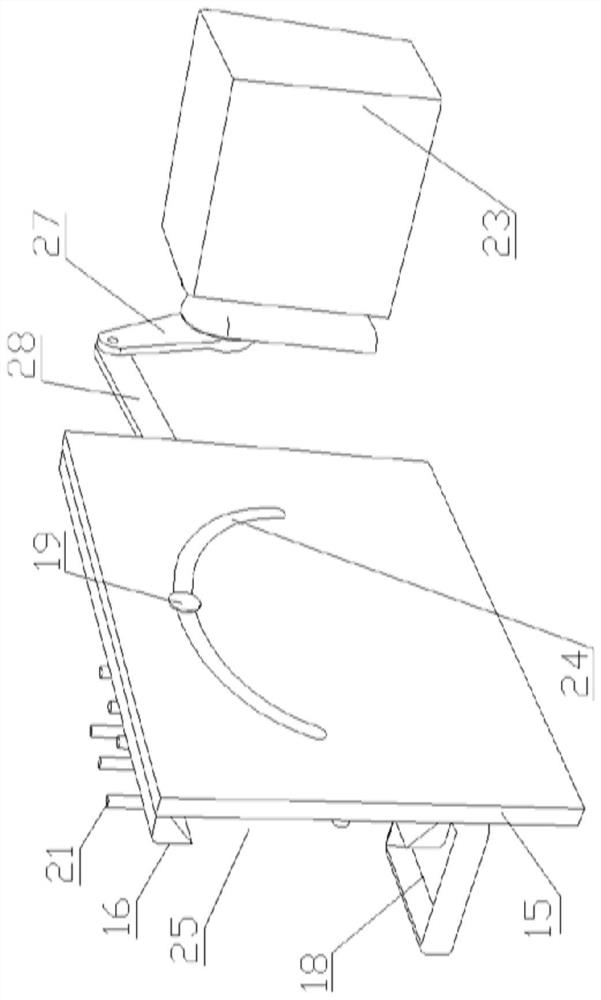

[0018] like figure 1 and figure 2 As shown, a cutting and printing integrated device includes a belt conveyor 1, a cutting mechanism 2 and a printing mechanism 3;

[0019] The belt conveyor 1 is supported on the ground by the frame A, and its length direction extends along the left and right directions;

[0020] Described cutting mechanism 2 comprises frame B4, the conveying unit that is supported on belt conveyor 1 bearing surface by frame B4, the cutter unit that is set on belt conveyor 1 top by support A5; Conveyor 1 is composed of multiple dessert guide beams 6 distributed in the width direction, the length direction of multiple snack guide beams 6 is consistent with the length direction of belt conveyor 1, and its two ends extend to the outside of belt conveyor 1 two ends, The lower end surfaces of multiple dim sum guide beams 6 are flush with each other, and are in clearance fit with the bearing surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com