Toggle rod overturning mold clamping mechanism and injection molding machine

A toggle lever and clamping technology, which is applied in the field of toggle lever eversion-type clamping mechanism and injection molding machine, can solve the problems of low market stock and production, difficult design of push plates, and failure of the push plate, so as to simplify the design of push plates. , Eliminate the risk of fracture failure, enhance the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

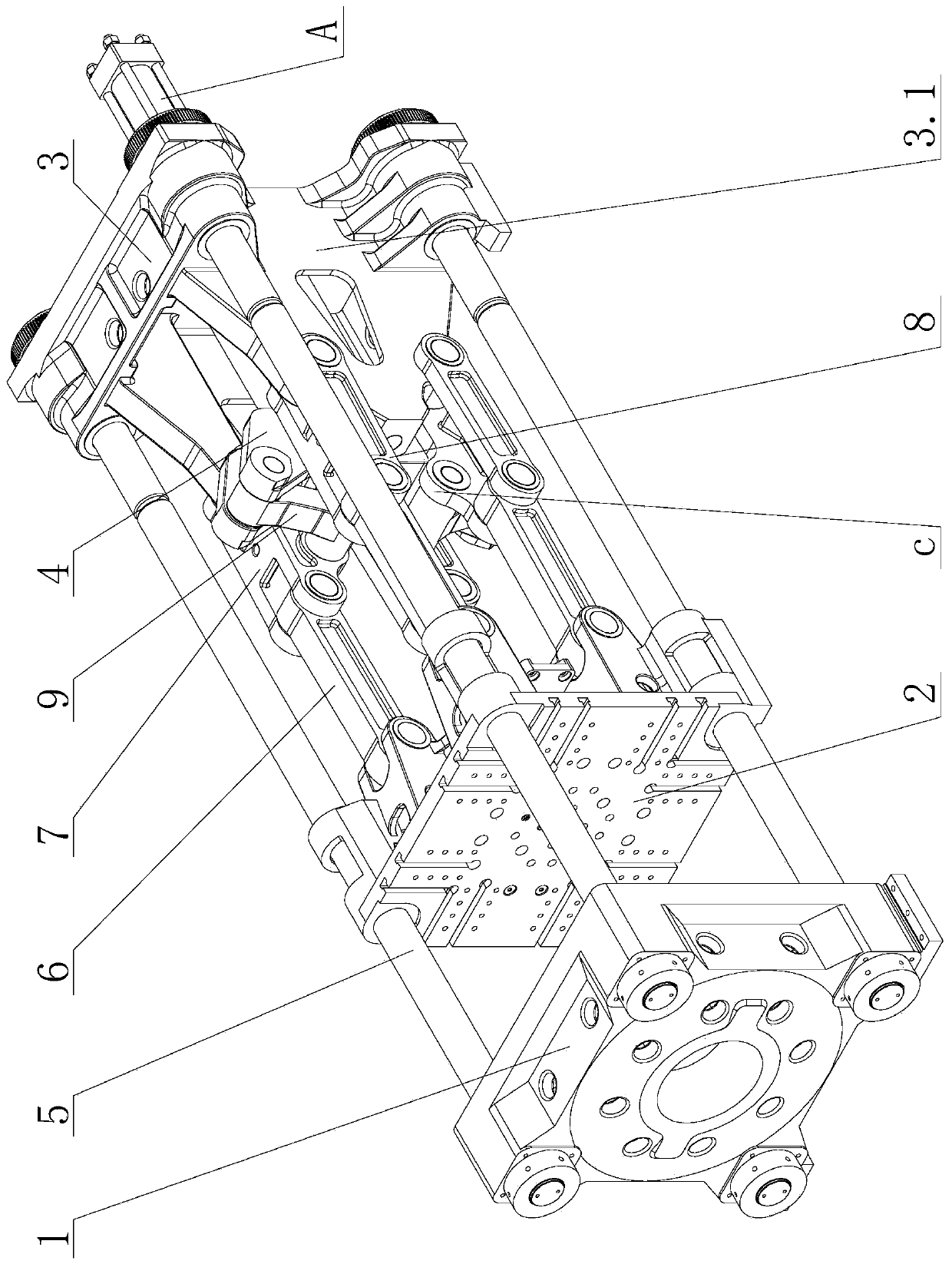

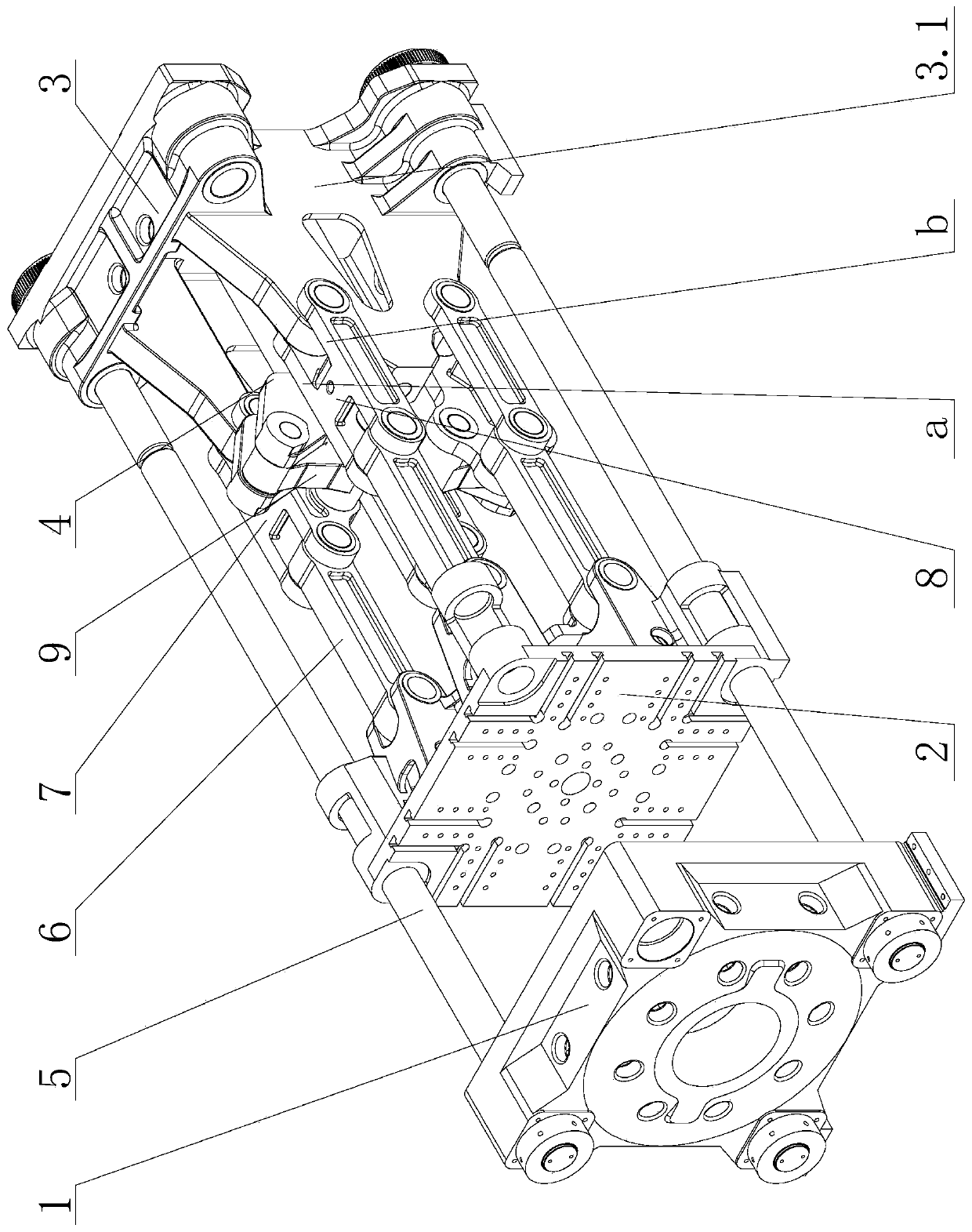

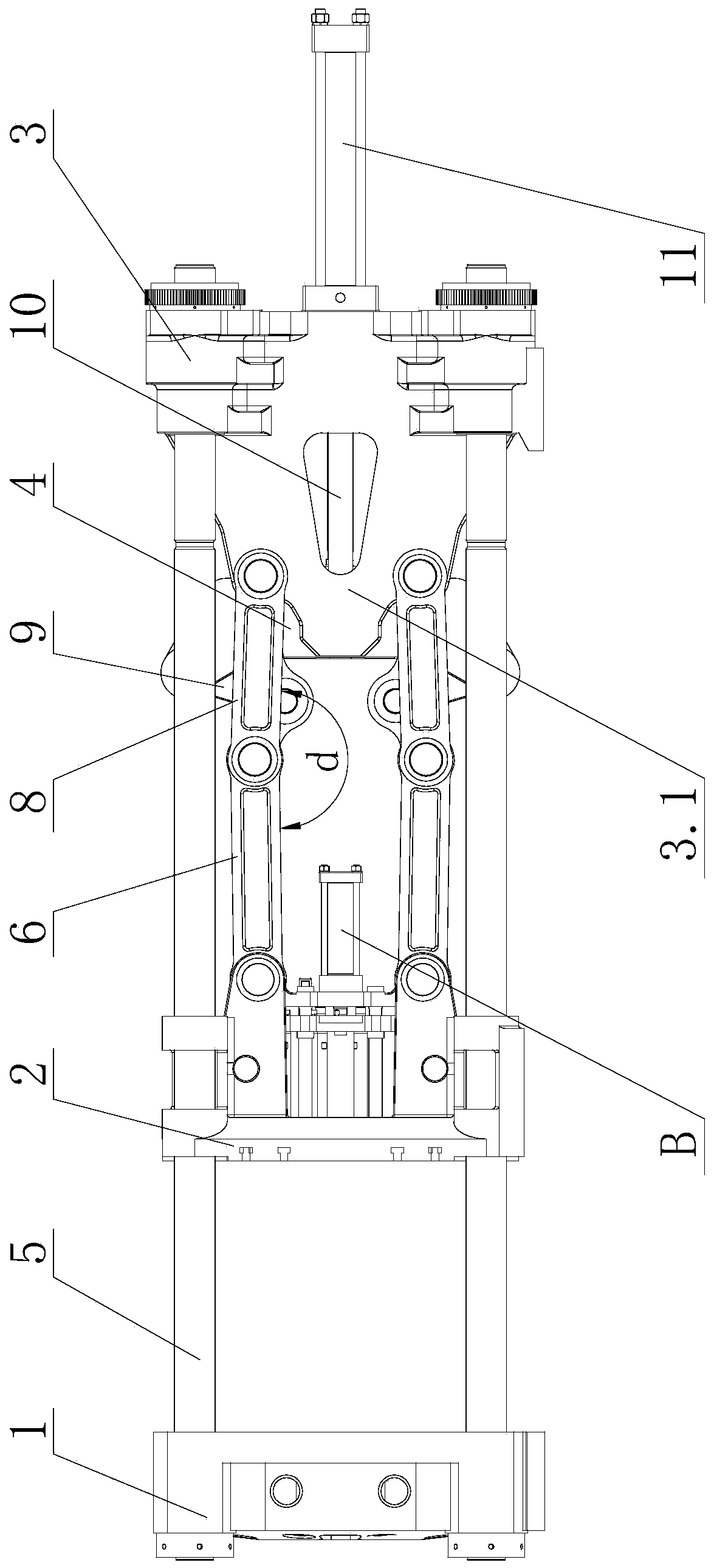

[0026] see Figure 1-Figure 9 , this toggle lever eversion type clamping mechanism includes a fixed platen 1, a movable platen 2, a tail plate 3 and a push plate 4, and the fixed platen 1, the movable platen 2, the tail plate 3 and the push plate 4 are all located on the same central axis, The movable formwork 2 is located between the fixed formwork 1 and the tail plate 3, four tie rods 5 are fixedly arranged between the fixed formwork 1 and the end plate 3, the tie rods 5 pass through the movable formwork 2, and the movable formwork 2 can move axially along the tie rods 5, Also comprise front toggle lever 6, first rear toggle lever 7, second rear toggle lever 8 and connecting toggle lever 9, connecting toggle lever 9 is a small toggle lever, one end of the first rear toggle lever 7 and the second rear toggle lever 8 Both are hinged to the tail plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com