Closed oily sewage treatment system

A treatment system and technology for oily sewage, applied in flotation water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of unstable hydraulic state, easy clogging, and poor oil removal effect Good and other problems, to achieve the effect of easy management and beautification of the ground environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, characteristics and details of the closed oily sewage treatment system proposed according to the present invention will be described below. Its effect is described in detail below.

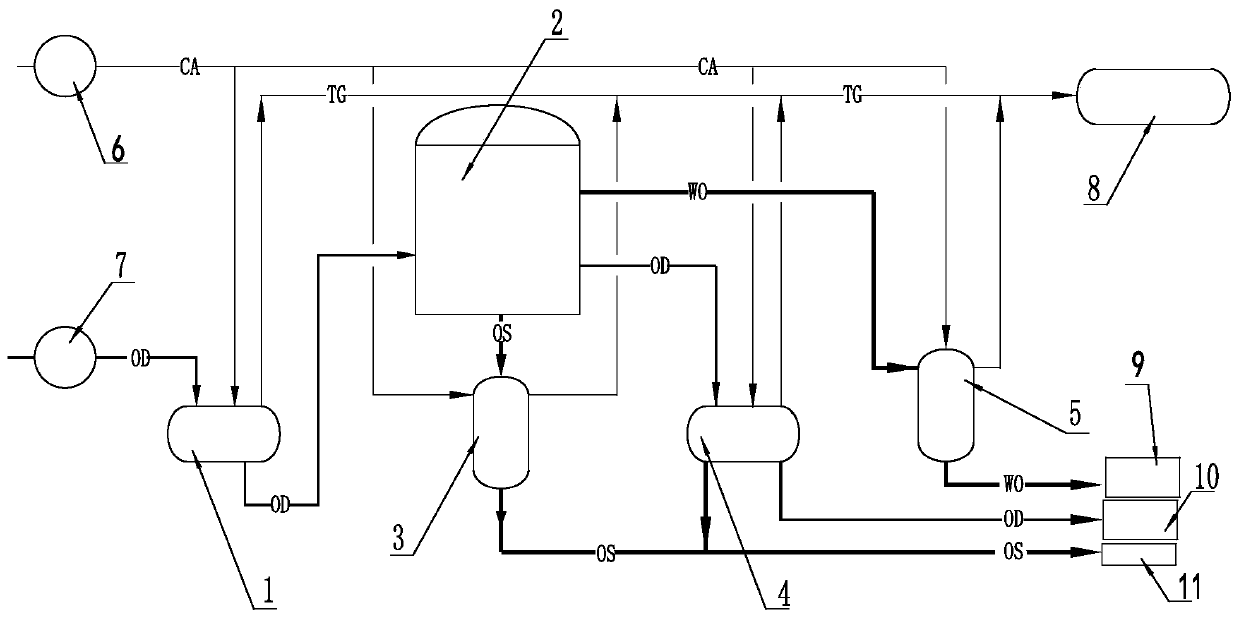

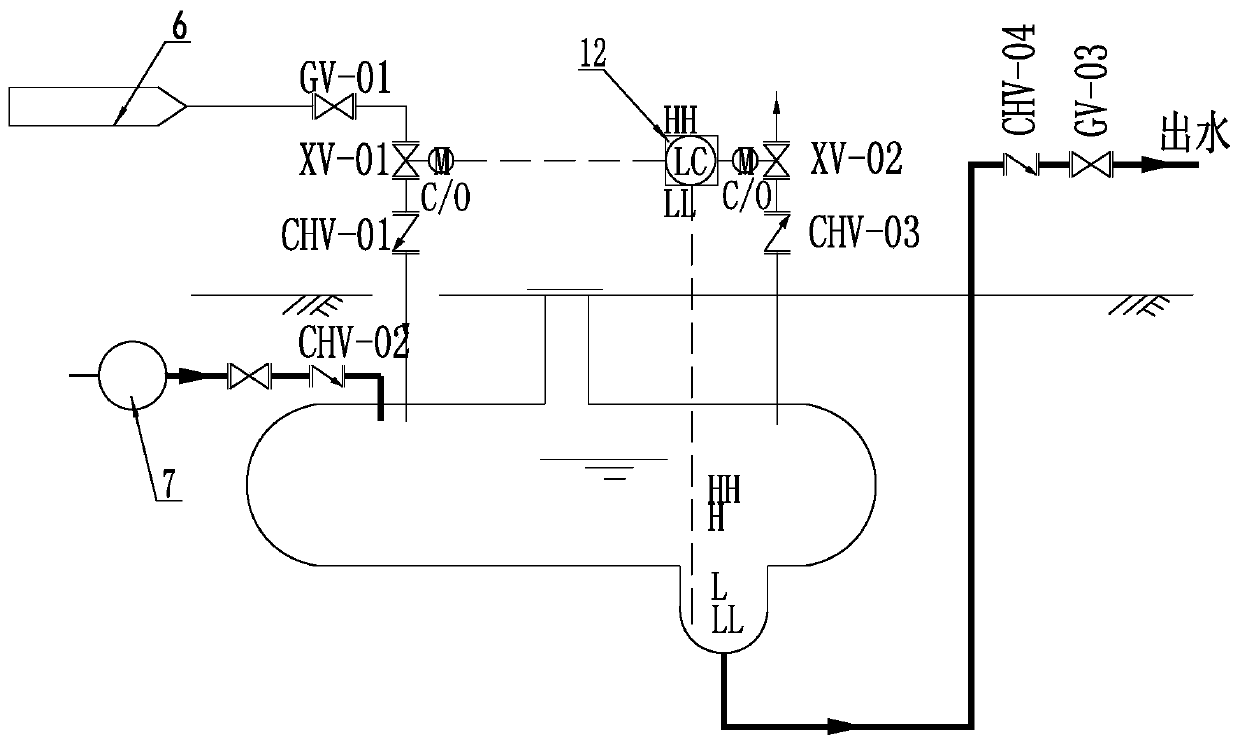

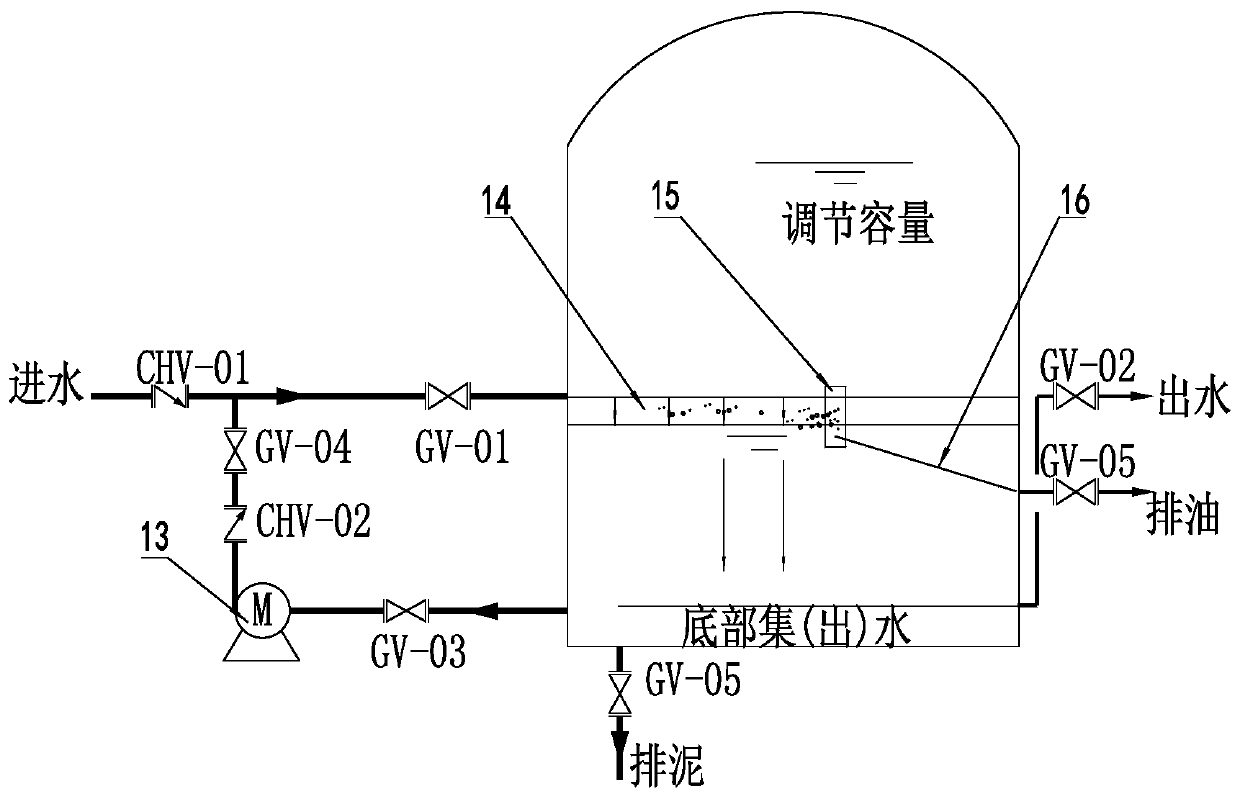

[0047] see Figure 1-3 , which is a structural schematic diagram of each part of the closed oily sewage treatment system of the present invention, the system includes a closed sewage lifting tank 1 for collecting and transporting oily sewage, and the water outlet at the bottom of the sewage lifting tank is removed through a pipeline and a closed equalizer The water distributor 14 on the oil tank 2 is connected to the water inlet, and the equalized oil removal tank 2 transports the dirty oil to the dirty oil lifting tank 5 through the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap