A garden artificial lawn laying device

A technology of artificial turf and laying device, which is applied in roads, buildings, road repairs, etc. It can solve the problems of limited turf size and inability to lay turf at one time, and achieve the effect of accurate laying position, normal laying and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

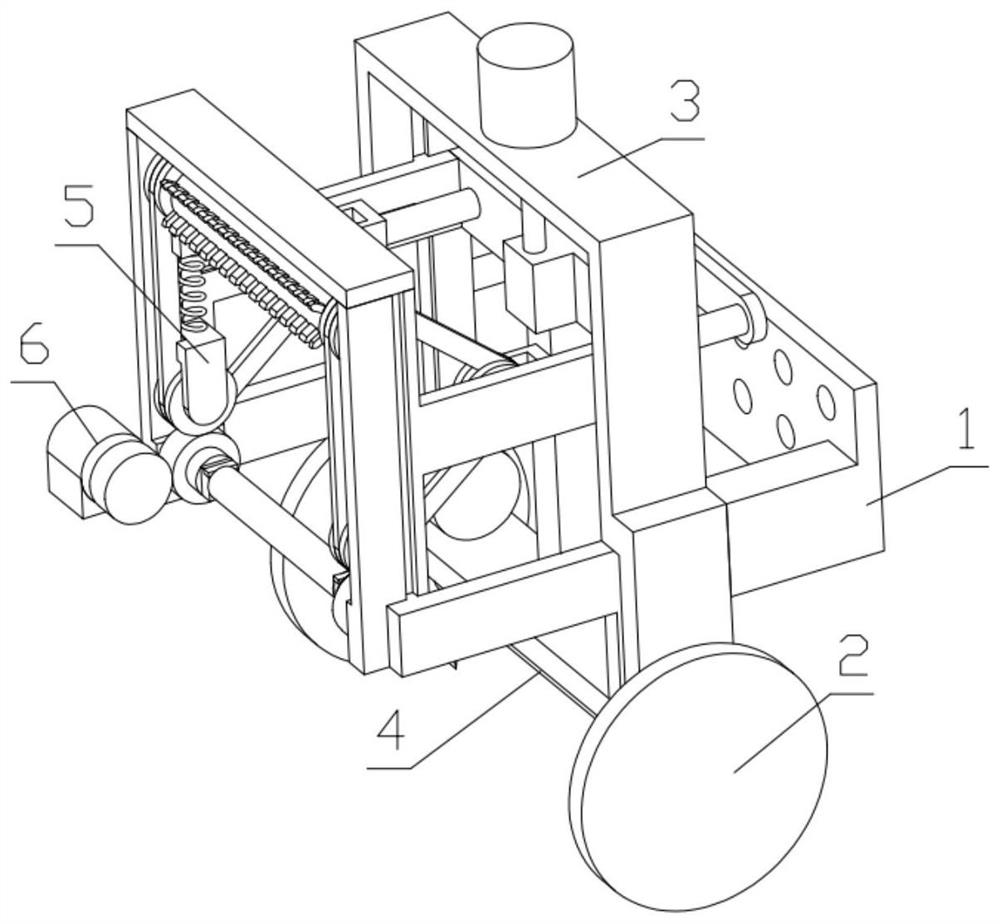

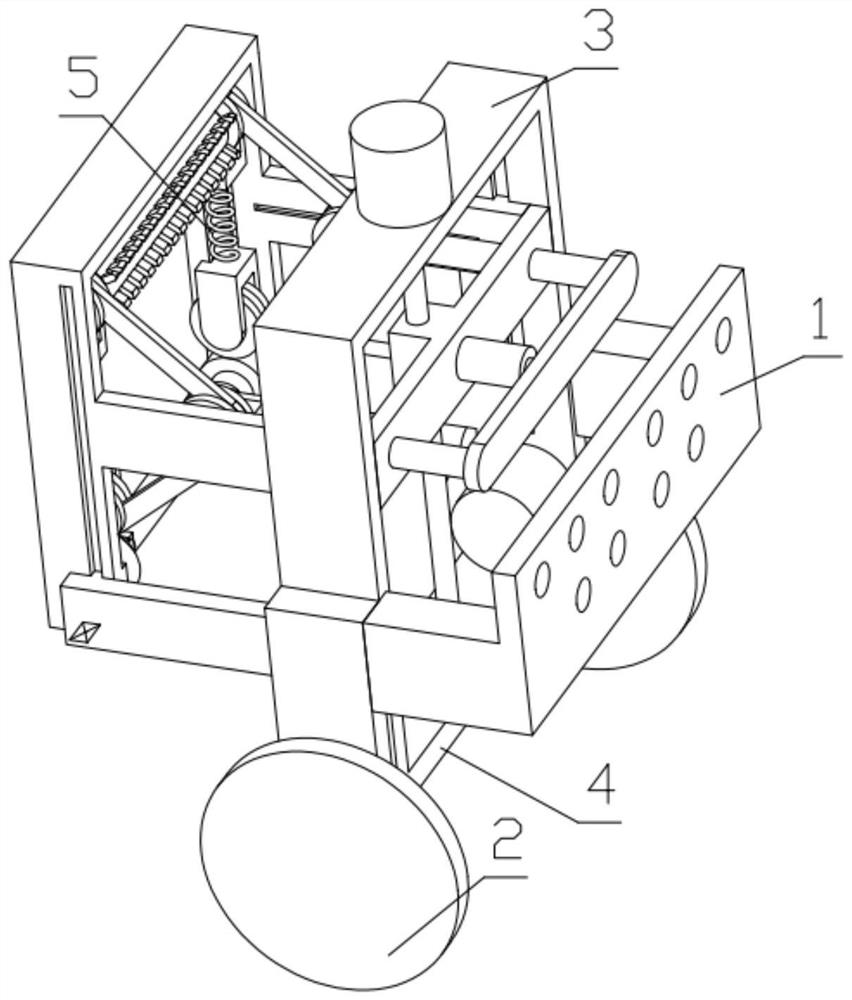

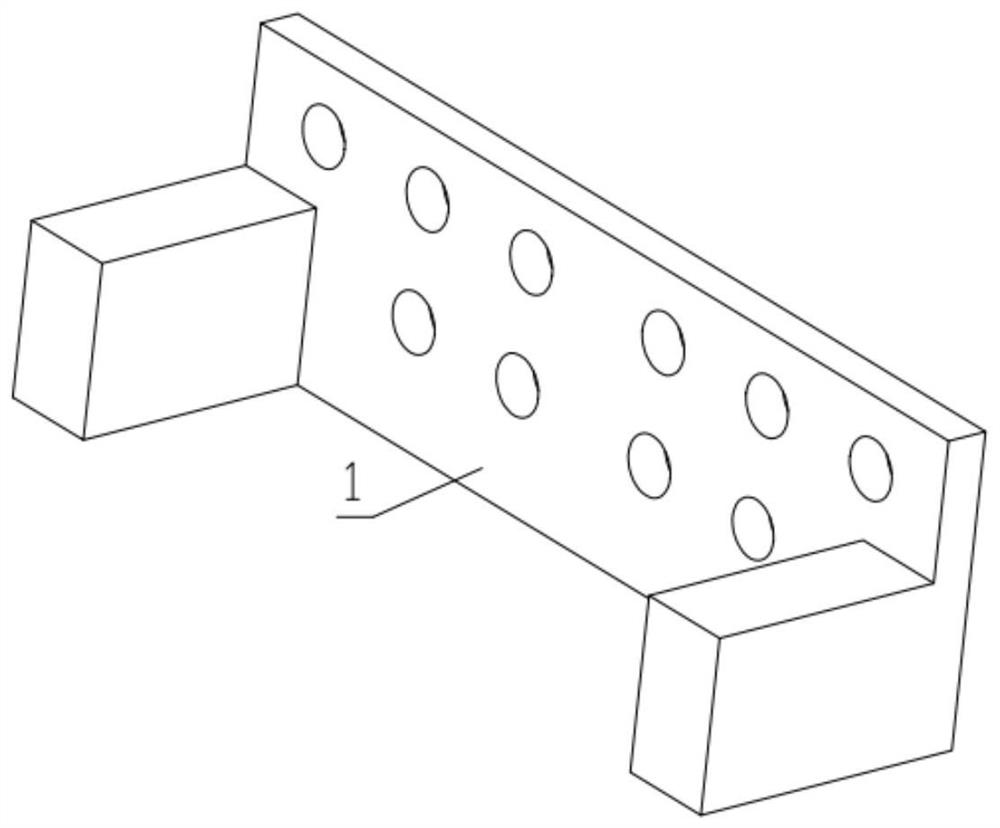

[0034] Combine below Figure 1-15 Description of this embodiment, a garden artificial lawn laying device, including an agricultural locomotive connecting plate 1, a moving wheel 2, and a device mounting frame 3, the agricultural locomotive connecting plate 1 is fixedly mounted on the device mounting frame 3, and the moving wheel 2 is rotatably mounted on the device On the installation frame 3 , the cutting mechanism 4 is installed on the device installation frame 3 , and the unwinding mechanism 5 is installed on the device installation frame 3 .

specific Embodiment approach 2

[0035] Combine below Figure 1-15 This embodiment will be described. This embodiment will further explain the first embodiment. The device installation frame 3 includes a frame main body 3-1, a lift adjustment motor 3-2, and a threaded column 3-3. The lift adjustment motor 3-2 passes through the The through hole provided on the frame main body 3-1 is fixedly installed on the frame main body 3-1, and one end of the threaded post 3-3 is rotatably installed on the groove provided on the frame main body 3-1, and the other end of the threaded post 3-3 One end is fixedly installed on the output end of the lifting adjustment motor 3-2, and the gear motor 6 is fixedly installed on the unwinding mechanism 5, and the lifting adjustment motor 3-2 is started to rotate the threaded column 3-3, and then the connecting beam 5-2 Driving the unwinding mechanism 5 to move downward as a whole will shorten the distance between the lawn roll and the ground, so that the lawn can be laid accurately....

specific Embodiment approach 3

[0036] Combine below Figure 1-15Describe this embodiment, this embodiment will further explain the second embodiment, the cutting mechanism 4 includes a threaded rod 4-1, a cutter 4-2, a threaded moving part 4-3, a driven gear 4-4, a driving Gear 4-5, motor 4-6, motor 4-6 passes through the through hole provided on the frame main body 3-1 and is fixedly installed on the frame main body 3-1, and driving gear 4-5 is fixedly installed on the motor 4-6 output end, the driving gear 4-5 meshes with the driven gear 4-4, the driven gear 4-4 is fixedly installed on one end of the threaded rod 4-1, and the other end of the threaded rod 4-1 is rotatably mounted on the frame main body 3-1 On the groove provided above, the threaded rod 4-1 is threadedly connected with the threaded moving part 4-3, the threaded moving part 4-3 is fixedly equipped with a cutter 4-2, and the threaded moving part 4-3 is slidably installed on the frame main body 3 On the groove provided on -1, since the lawn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com