Collision damping guardrail for roads and bridges

A technology for guardrails and road bridges, which is applied in the direction of springs/shock absorbers, roads, bridges, etc. It can solve problems such as unfavorable construction and long guardrails, and achieve the effects of avoiding protection failure, buffering impact force, and protecting passenger safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] see Figure 1 to Figure 4 , the present invention provides a technical solution:

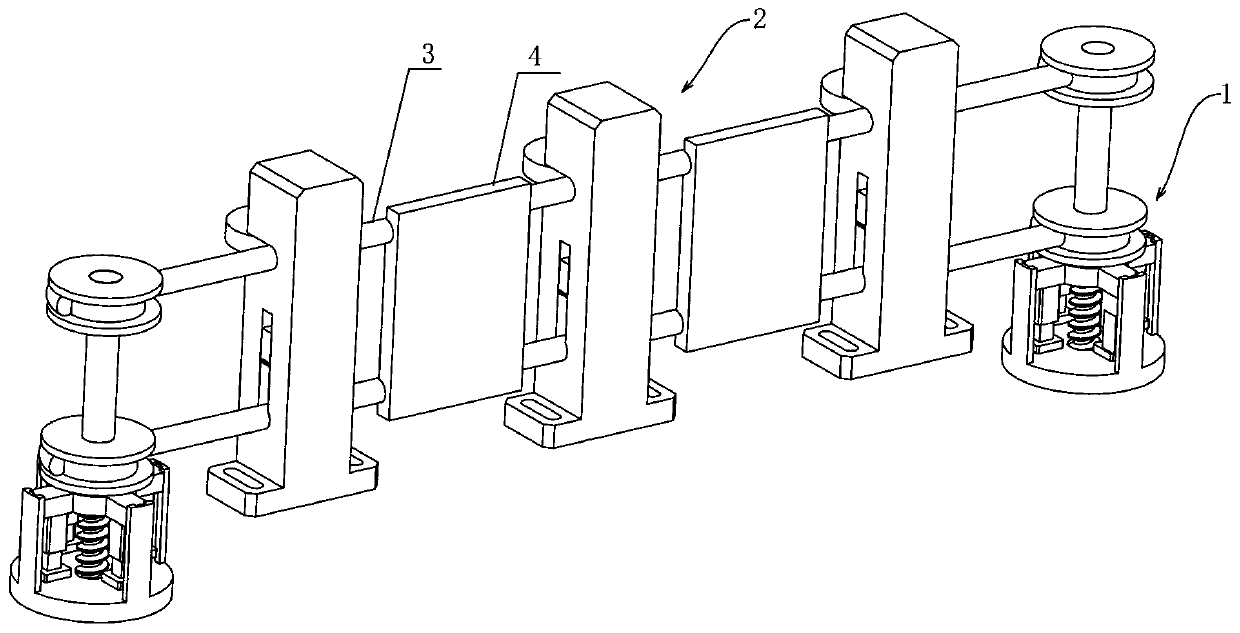

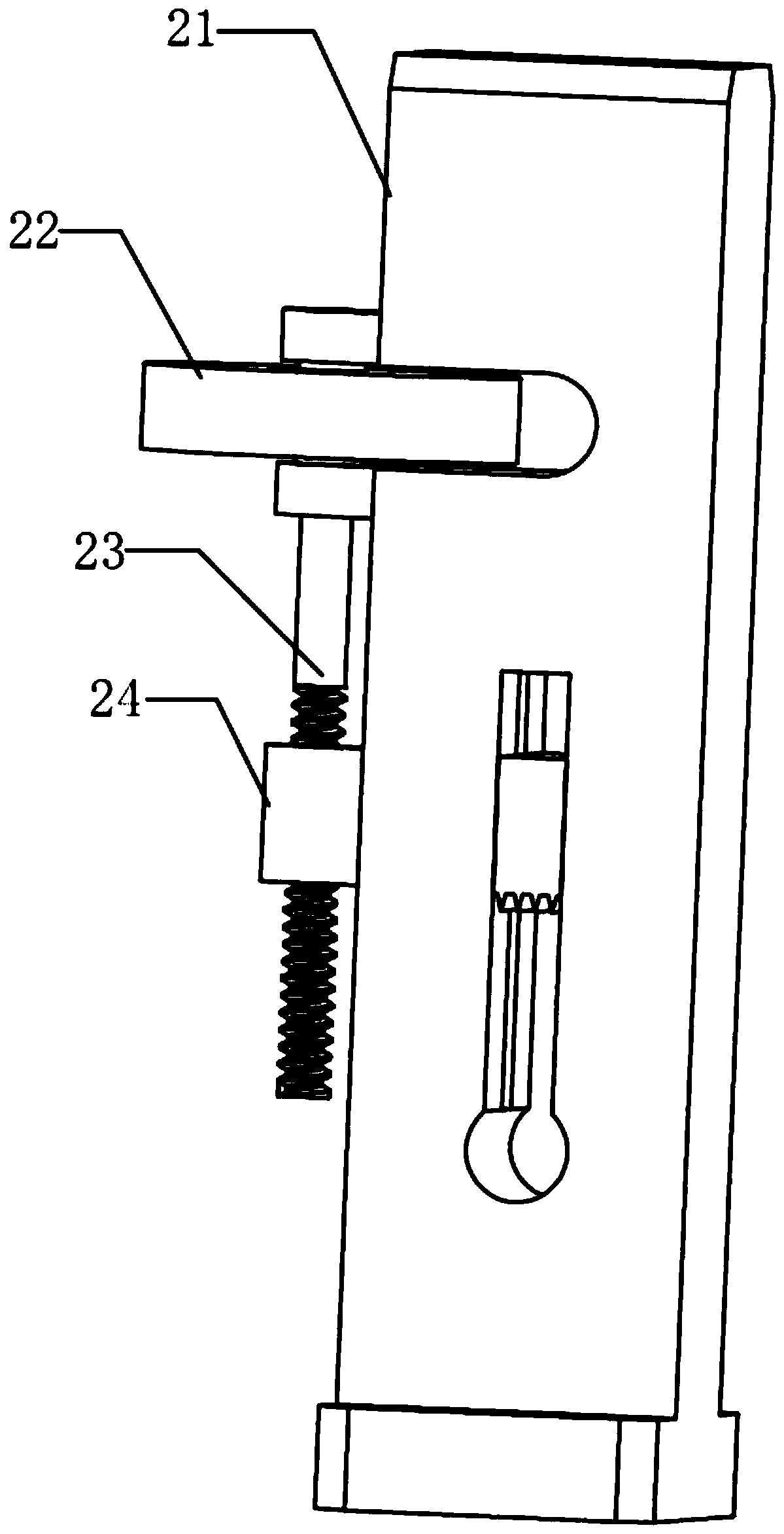

[0022] A collision damping guardrail for a road and bridge, including a buffer mechanism 1, a column assembly 2, a steel cable 3 and a guard plate 4, wherein:

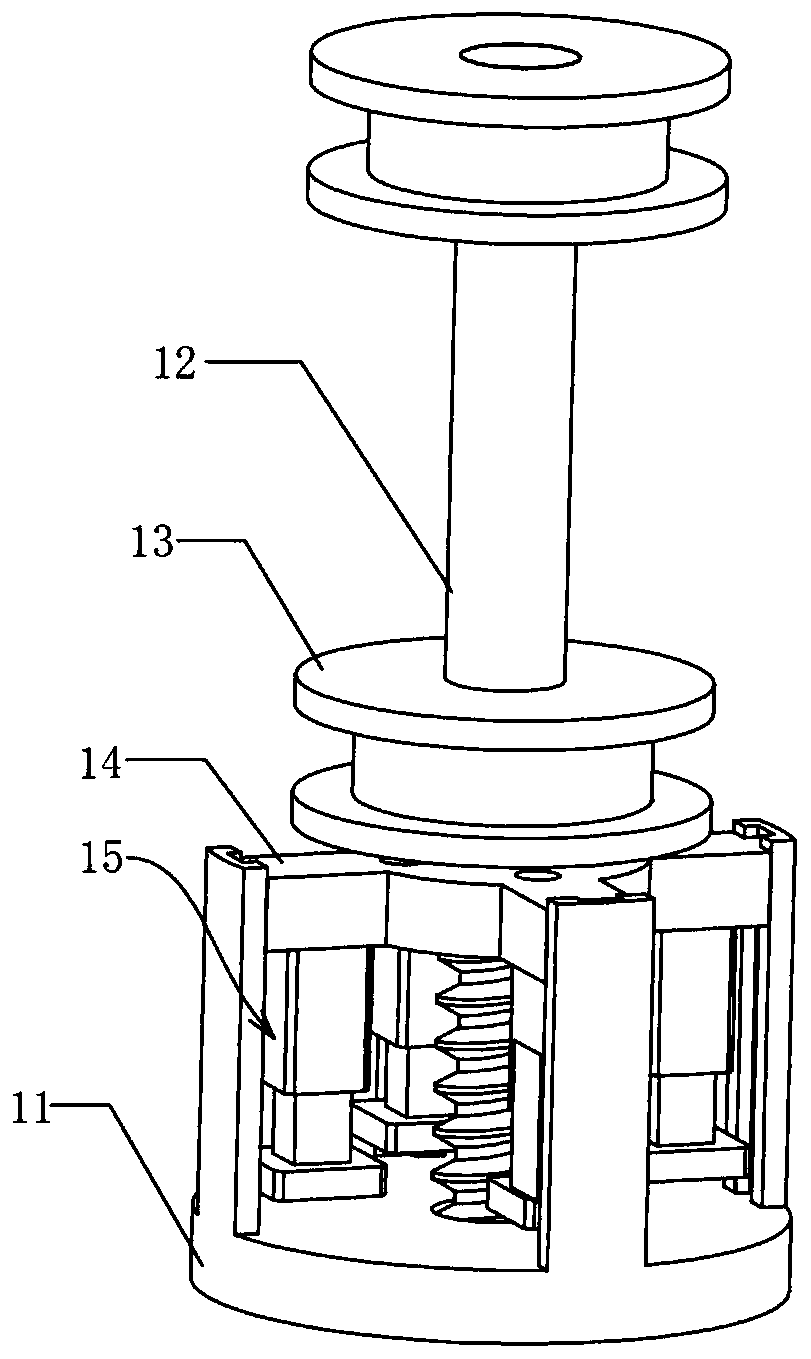

[0023] At least two column assemblies 2 are arranged side by side, and the number of column assemblies 2 is selected according to the construction distance. Two buffer mechanisms 1 are respectively located on both sides of the column assemblies 2 arranged side by side. The buffer mechanism 1 includes a bottom plate 11, a rotating shaft 12, a steel cable The disc 13, the movable disc 14 and the telescopic rod assembly 15, the base plate 11 is used to be fixedly installed on the ground or the bridge surface, the rotating shaft 12 is installed on the base plate 11 through bearings, and the two cable discs 13 are fixedly sleeved on the rotating shaft 12 respectively, The movable disc 14 is movably installed on the baffle plate on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com