A municipal road surface isolation guardrail cleaning device

A cleaning device and guardrail technology, applied in road cleaning, cleaning methods, construction, etc., can solve the problems that both sides of the guardrail cannot be cleaned at the same time, it is not easy to promote and implement, and the guardrail cannot be cleaned, etc., so as to achieve strong applicability, avoid dead ends, and improve The effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

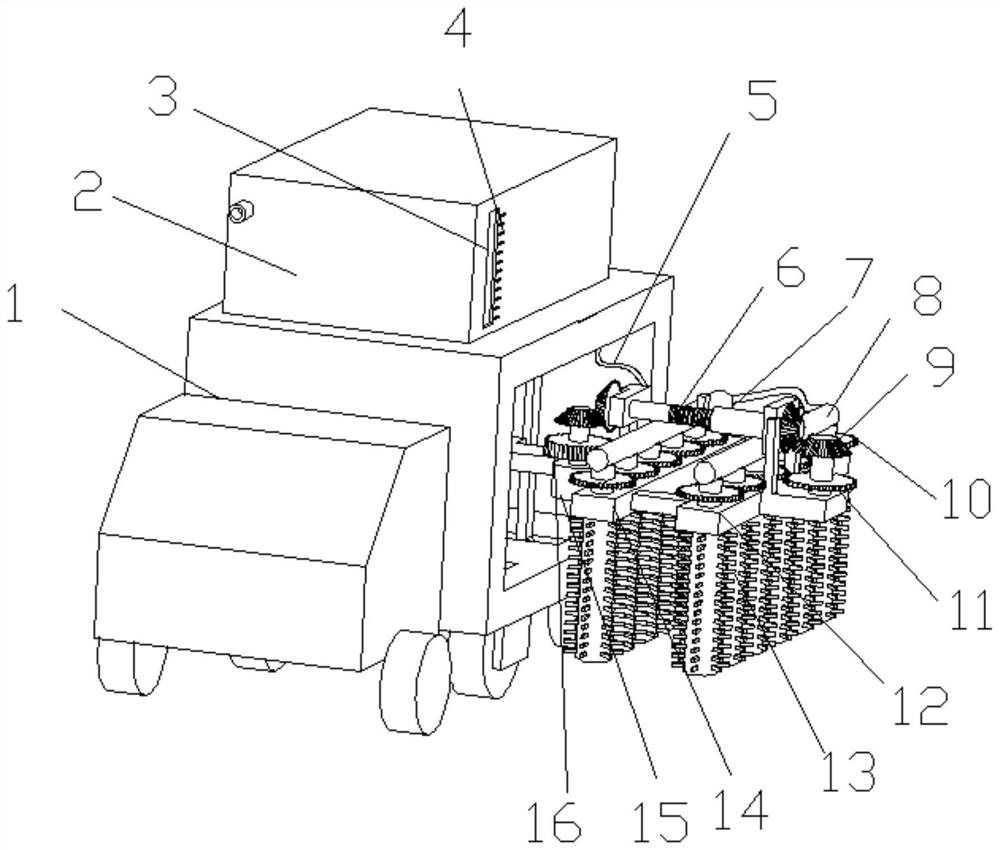

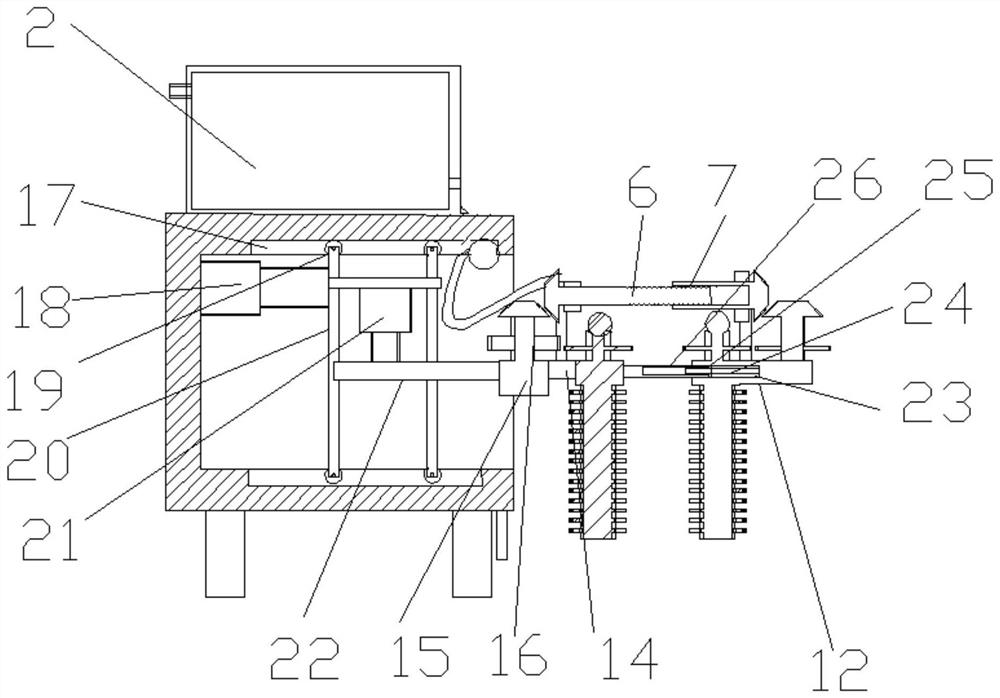

[0026] see Figure 1-4 , a municipal road surface isolation guardrail cleaning device, including a compartment 1, a brush roller 13 and a first mounting frame 12. The interior of the compartment 1 is slidingly provided with a horizontal moving frame 20, the inner side wall of the compartment 1 is fixedly connected to one end of the first hydraulic rod 18, and the other end of the first hydraulic rod 18 is fixedly connected to the horizontal moving frame 20. Telescoping, drive the horizontal moving frame 20 to slide inside the compartment 1, the top and bottom of the horizontal moving frame 20 are rotated and provided with pulleys 19, and the upper and lower sides of the horizontal moving frame 20 are provided with sliding grooves 17 and pulleys 19 at the inner bottom and top of the compartment 1 Nested inside the sliding groove 17, thereby reducing the frictional force between the horizontal moving frame 20 and the carriage 1, and making the sliding of the horizontal moving fr...

Embodiment 2

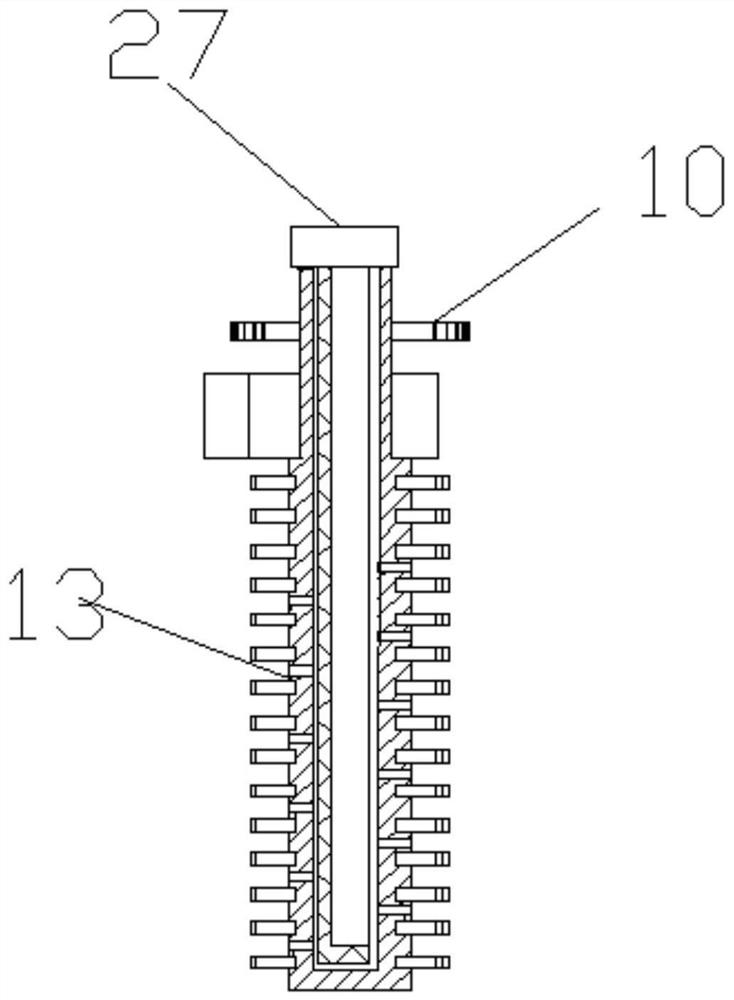

[0031] On the basis of Embodiment 1, a water tank 2 is arranged on the compartment 1, and a water pump is fixedly arranged inside the compartment 1. The water tank 2 communicates with the water pump, and the water pump communicates with the water pipe 8 through the hose 5. The brush roller 13 is a hollow structure and is provided with a spray The water hole, the internal rotation of the brush roller 13 is provided with an inner sleeve 27, the inner sleeve 27 is a C-shaped structure in cross section and the opening is towards the guardrail position, and the water pipe 8 is fixedly communicated with the inner sleeve 27. Under the action of the water pump, the water inside the water tank 2 enters the inside of the brush roller 13 and sprays out from the spray hole, thereby facilitating the cleaning of the guardrail. Under the action of the inner casing 27, the water is sprayed toward the guardrail in a directional manner, which prevents the water from spraying in other directions,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com