Throttling hydraulic system of excavator

A technology for hydraulic systems and excavators, which is applied to earth movers/shovels, fluid pressure actuators, mechanical equipment, etc., and can solve problems such as high cost, high strength of the main shaft of the pump body, and large space occupied by the pump body. Achieve the effect of reducing quantity, reducing weight and cost, and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

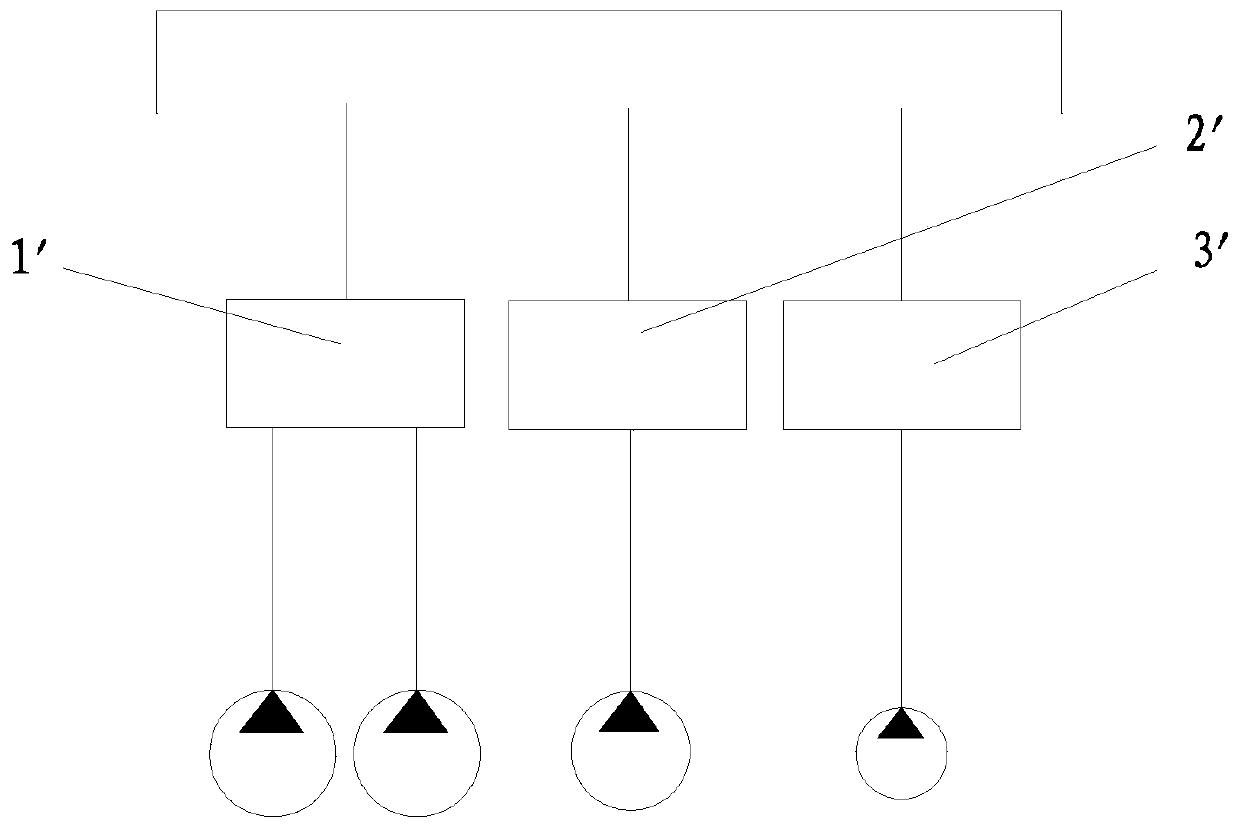

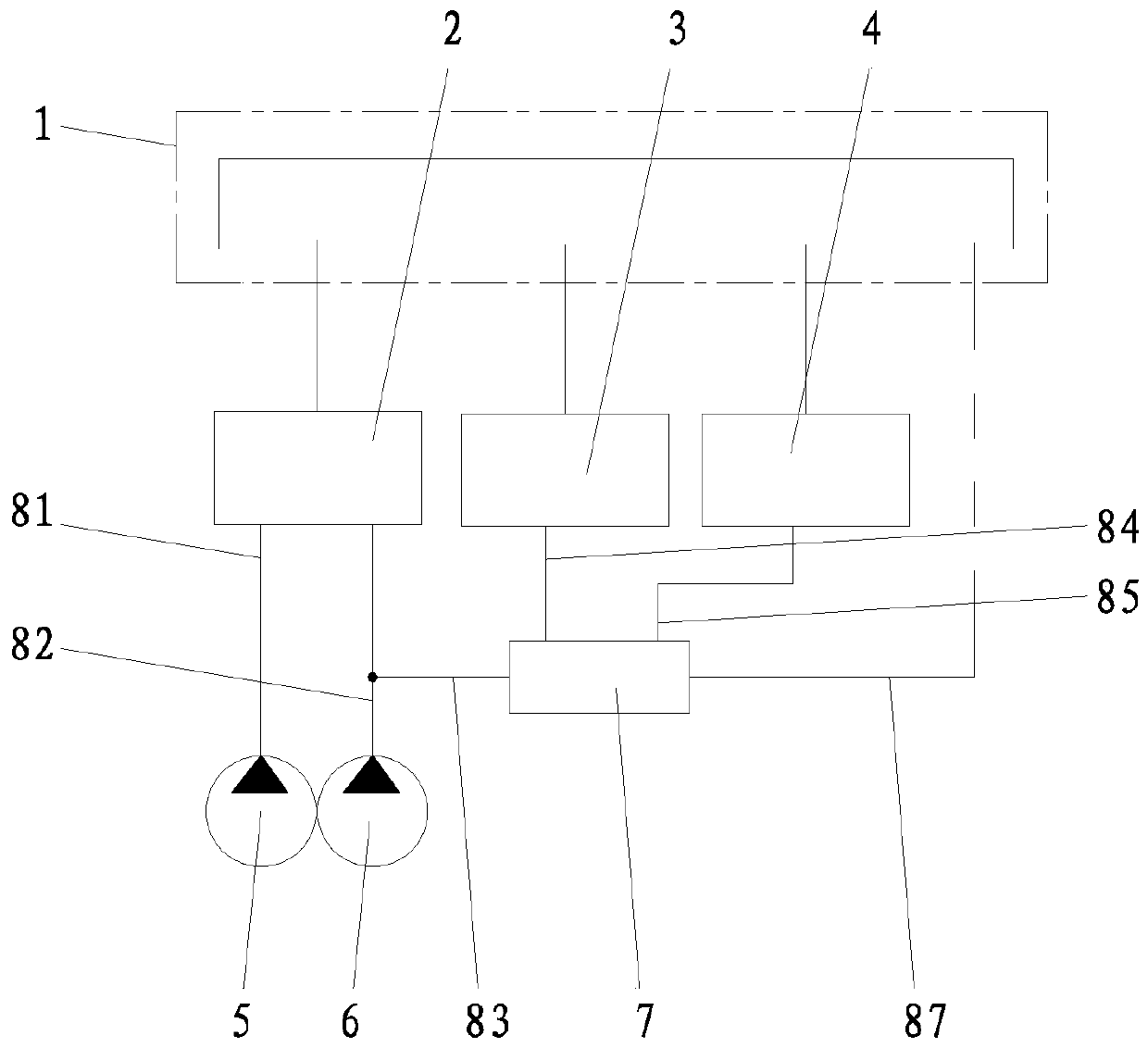

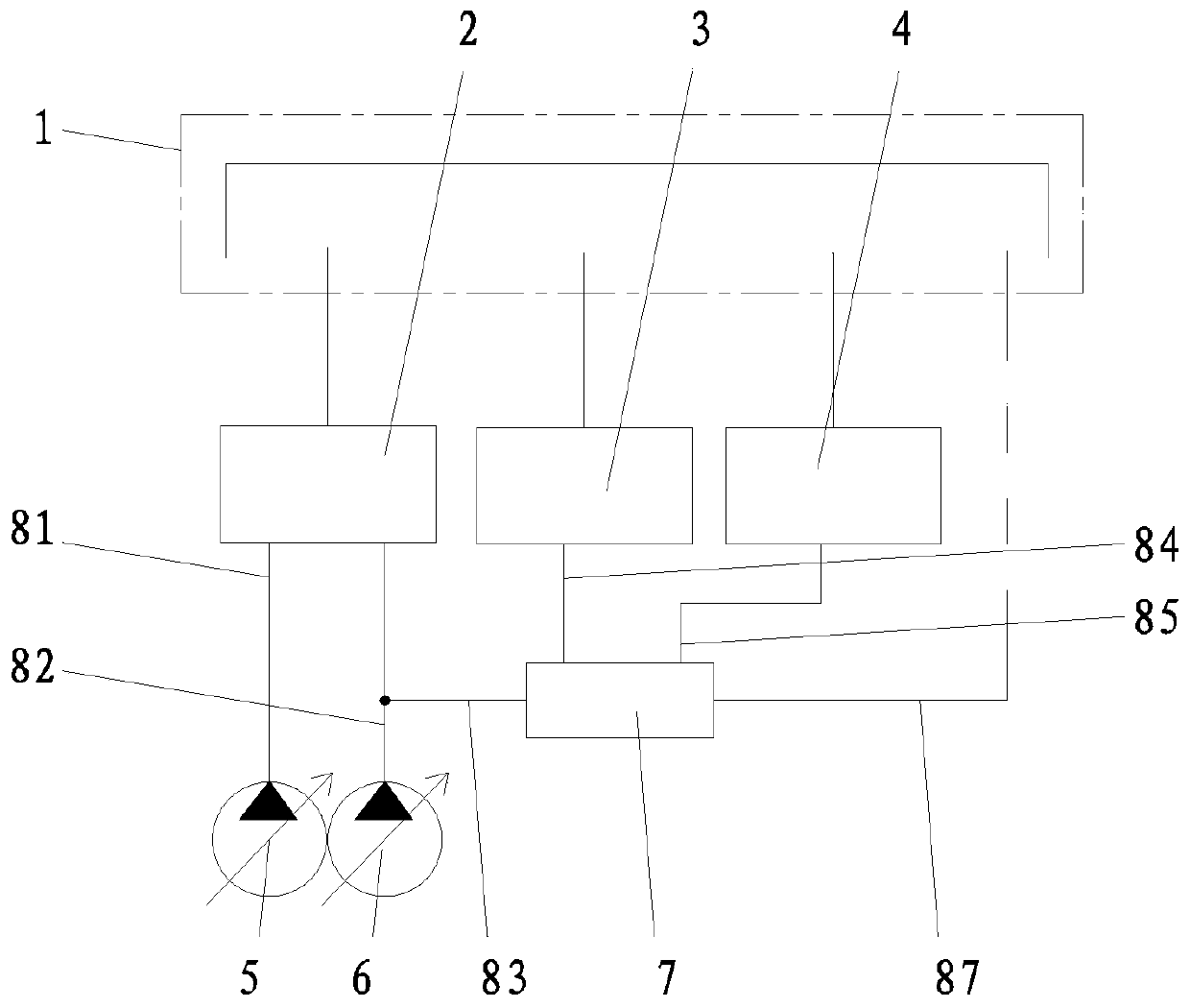

[0030] Such as Figure 2-5 As shown, an excavator throttling hydraulic system includes a hydraulic oil tank 1, and a multi-way valve 2, a steering gear 3 and a hydraulic pilot system 4 that are respectively communicated with the hydraulic oil tank 1, wherein it also includes a first pump body 5, a second The second pump body 6 and the secondary pressure reducing valve 7; the oil outlet end of the first pump body 5 has a main oil supply circuit 81 for supplying main working oil pressure to the oil inlet end of the multi-way valve 2 . The oil outlet end of the second pump body 6 has an auxiliary oil supply passage 82 for supplying oil to the oil inlet end of the multi-way valve 2, and the first oil supply passage 82 that divides the outflow part of the oil pressure from the auxiliary oil supply passage 82 to supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com