Temperature control medium conveying pipeline capable of being quickly assembled

A technology for temperature control media and pipelines, applied in hose connection devices, pipeline heating/cooling, pipes/pipe joints/fittings, etc., can solve the problems of lower heating energy consumption ratio, easy deformation, and inability to heat liquids, etc. To achieve the effect of increasing the heating area, preventing liquid seepage, and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

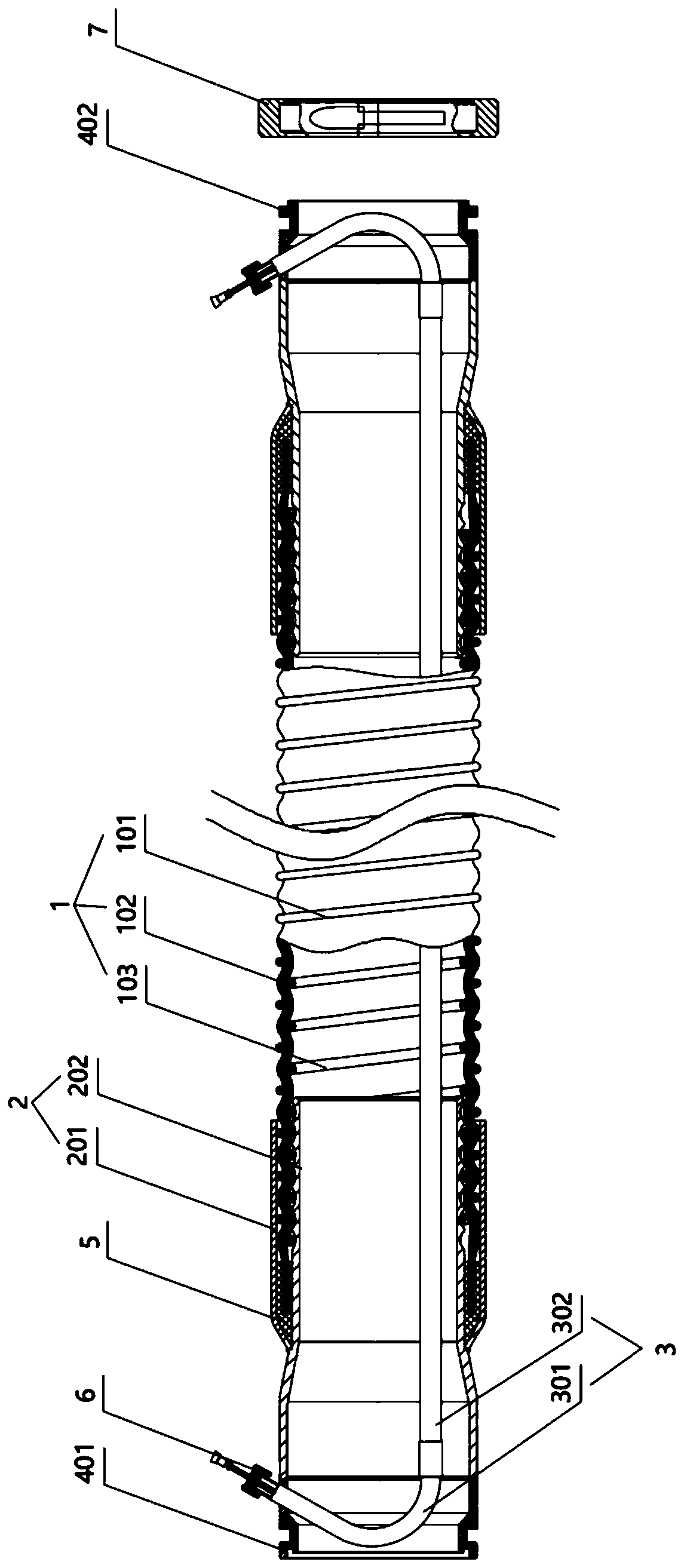

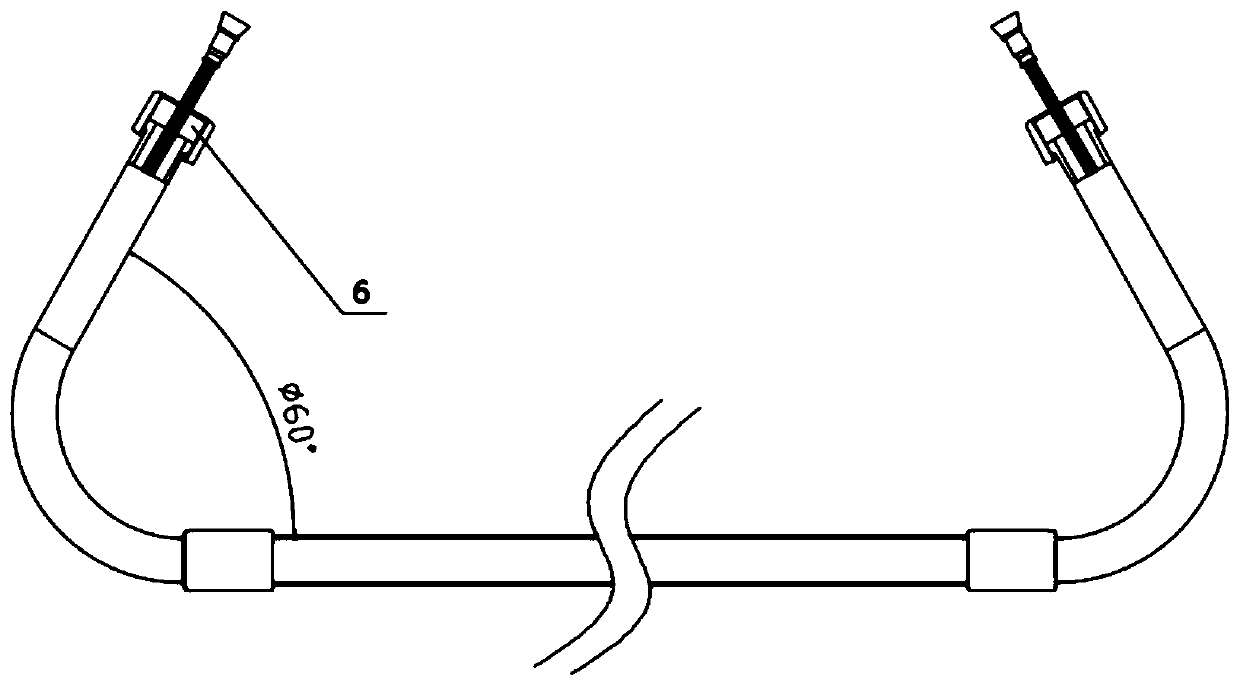

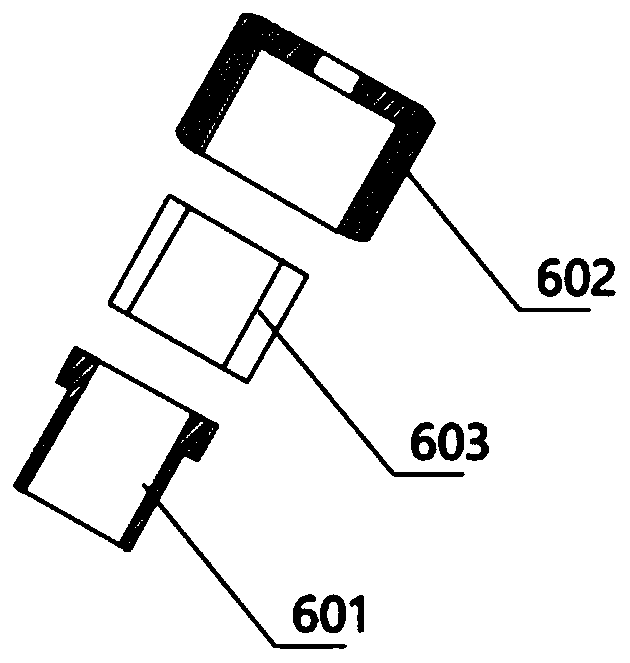

[0019] refer to Figure 1-5 , a temperature-controlled medium delivery pipeline that can be quickly assembled, comprising a plurality of sequentially connected heating composite hoses, the heating composite hoses include connecting sleeves 2 respectively arranged at the left and right ends of the composite hose 1, and arranged through The heating device 3 of the composite hose 1, the heating device 3 is connected to a power supply through a power cord, and the composite hose 1 includes an outer steel wire 101, a tensile layer 102, and an inner steel wire 103 arranged in sequence from outside to inside,

[0020] The connecting sleeve 2 includes the left and right ends respectively socketed on the composite hose 1, and the connecting sleeve 2 is respectively fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com