Fuel gas water boiler

A water boiler and gas technology, used in water heaters, lighting and heating equipment, fluid heaters, etc., can solve problems such as waste, hot surface, ineffective utilization, etc., to prevent shaking, improve work efficiency, and prevent water vapor. burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

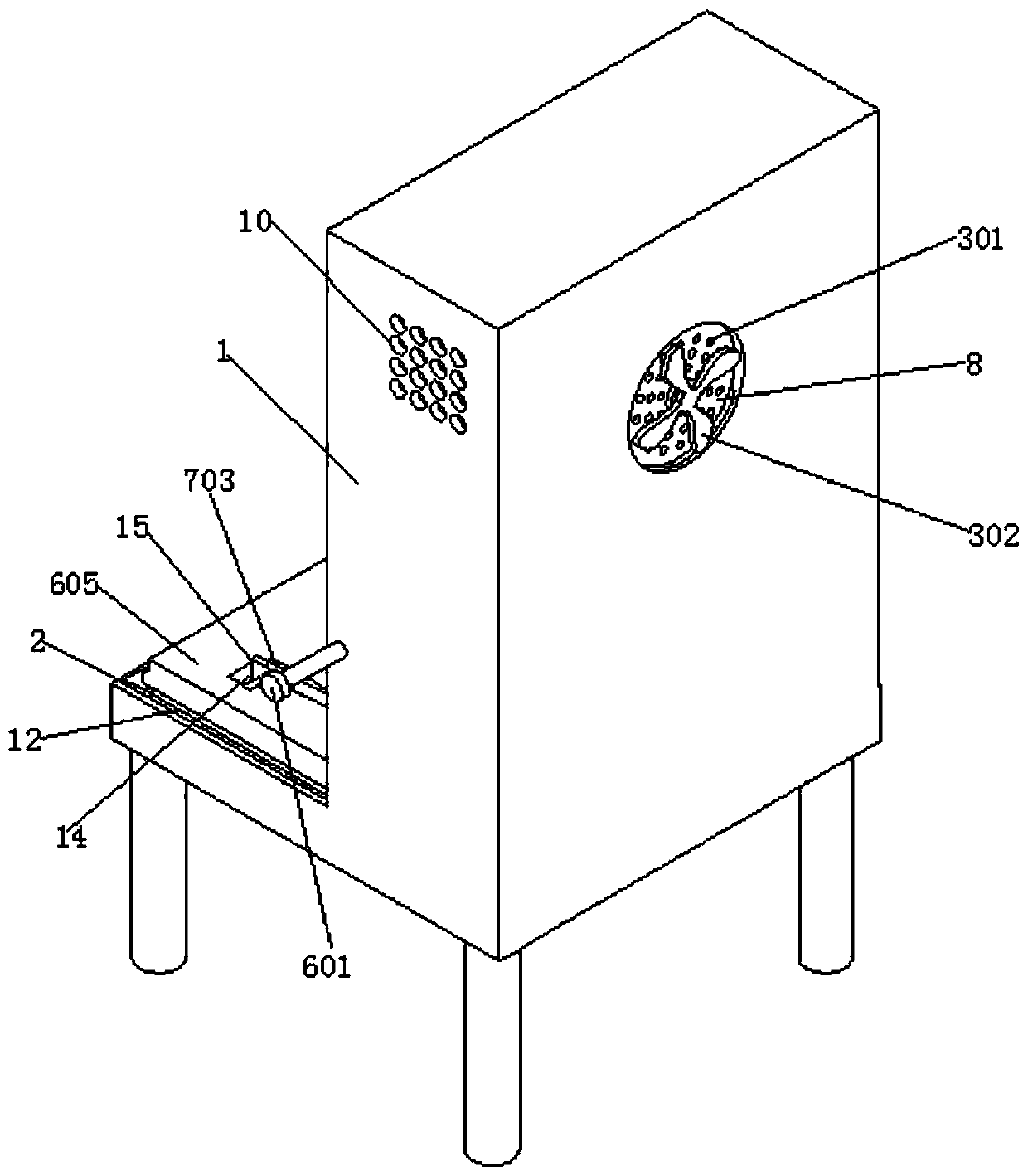

[0034] refer to Figure 6 and Figure 7 , the exhaust device 3 includes a mounting plate 301, fan blades 302 and a condensed water tray 303, the mounting plate 301 is fixed to the back side wall of the box body 1, and a plurality of cooling ports 8 are provided on the mounting plate 301, and the fan blades 302 pass through The rotating shaft is rotatably connected to the center of the mounting plate 301. The inner wall of the box body 1 is provided with a water storage channel 9. The condensed water pan 303 is located inside the box body 1, and the condensed water pan 303 communicates with the top of the water storage channel 9 through a pipeline. When the gas When the water boiler is working, the exhaust device 3 is started, and the air flow is accelerated through the fan blade 302, so that the combustion gas is more fully burned. The condensed water is accelerated to condense it, and the condensed water flows from the condensed water pan 303 through the pipeline into the wa...

Embodiment 2

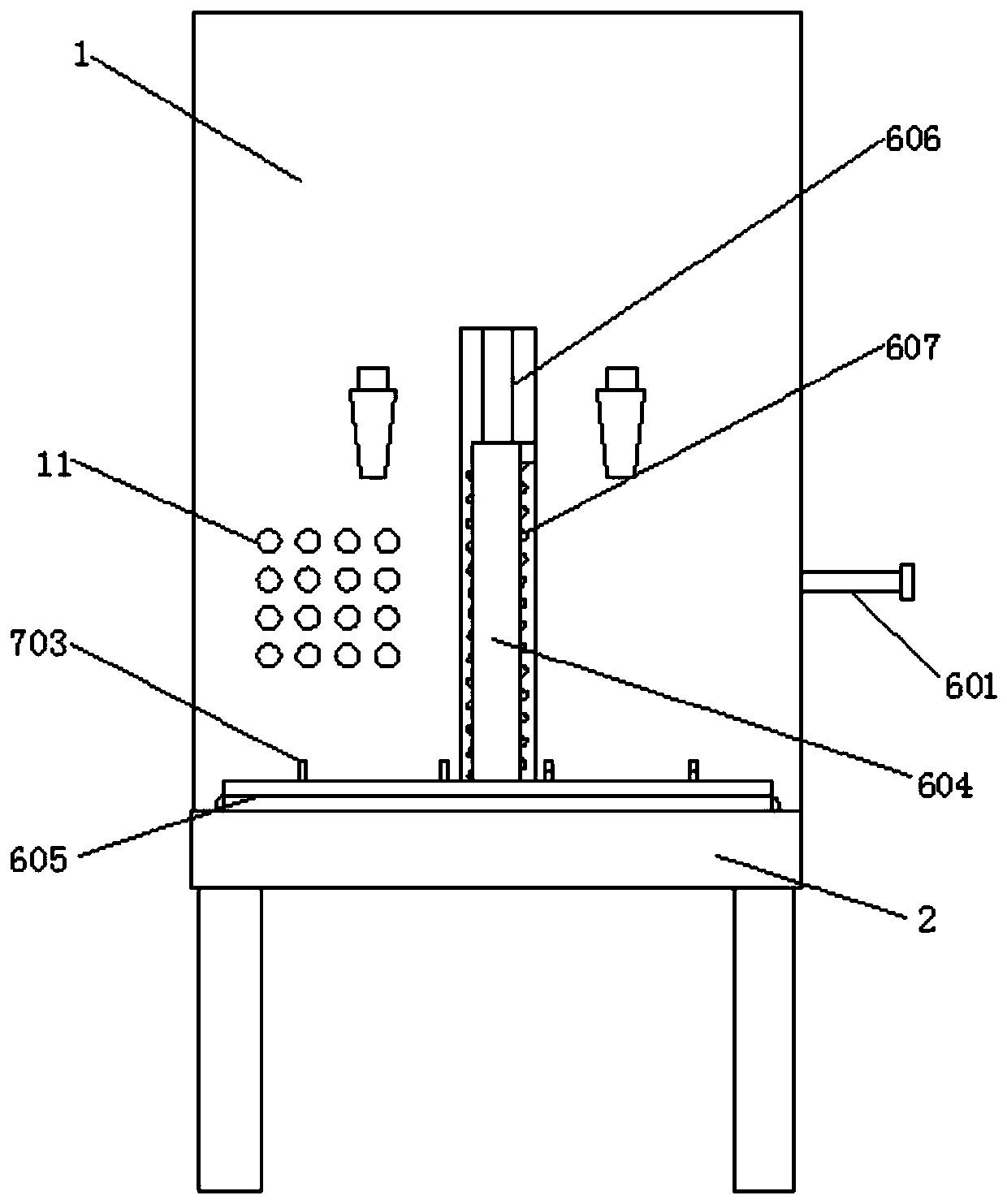

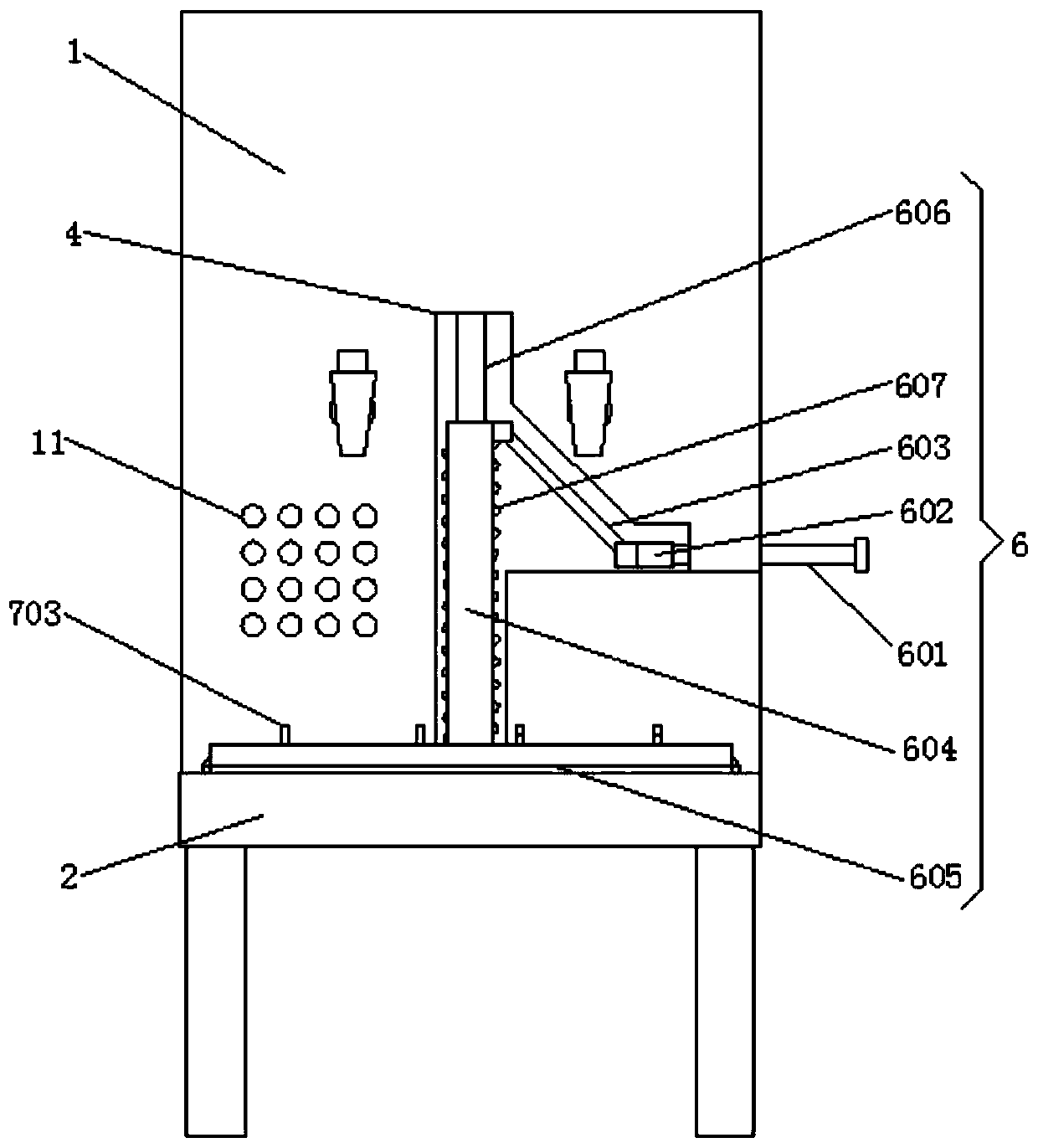

[0037] refer to Figure 1-5, the height adjustment device 6 includes a push rod 601, a connecting block 602, a rotating rod 603, an L-shaped plate 604, a water receiving panel 605, a fixed rod 606 and an ejection spring 607. One end is fixed, and is slidably connected with the inner wall of the sliding groove 5, and the two ends of the rotating rod 603 are respectively connected with one end of the connecting block 602 and one end of the L-shaped plate 604 through the pin shaft, and the bottom of the L-shaped plate 604 is connected with the water receiving panel. 605 is fixed, the fixed rod 606 is fixed to the inner walls of both ends of the installation groove 4, and one end of the L-shaped plate 604 is sleeved on the outside of the fixed rod 606, and is slidably connected with the fixed rod 606, and the ejection spring 607 is sleeved on the outside of the fixed rod 606, And the two ends of the ejection spring 607 are respectively fixed with the bottom inner wall of the insta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap