Tire structure design method and application thereof

A design method and tire technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as difficulty in obtaining material stress and strain values, lack of tire dynamic equilibrium state, poor tire durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

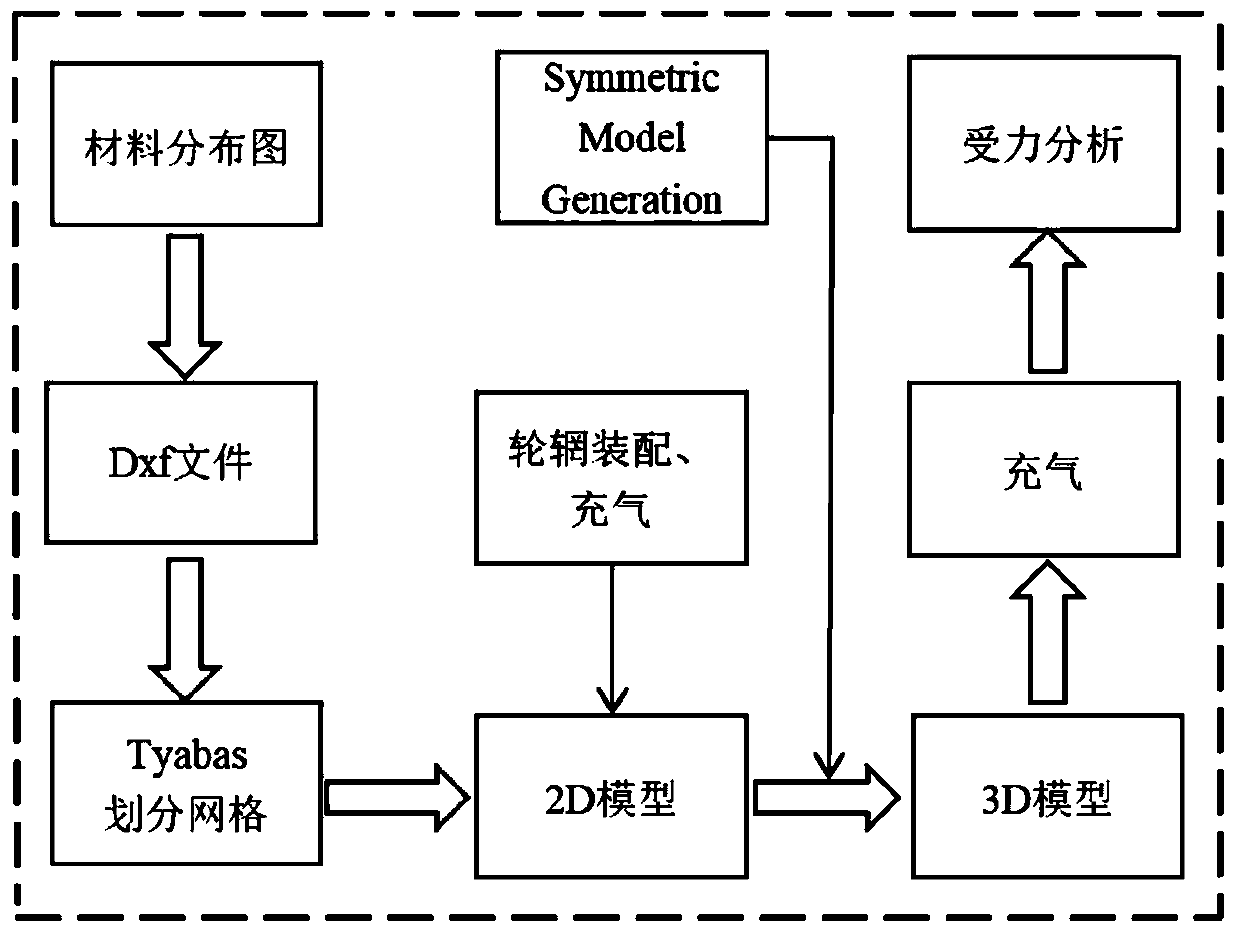

[0032] Preliminary establishment of the overall tire performance simulation analysis process as follows: figure 1 shown.

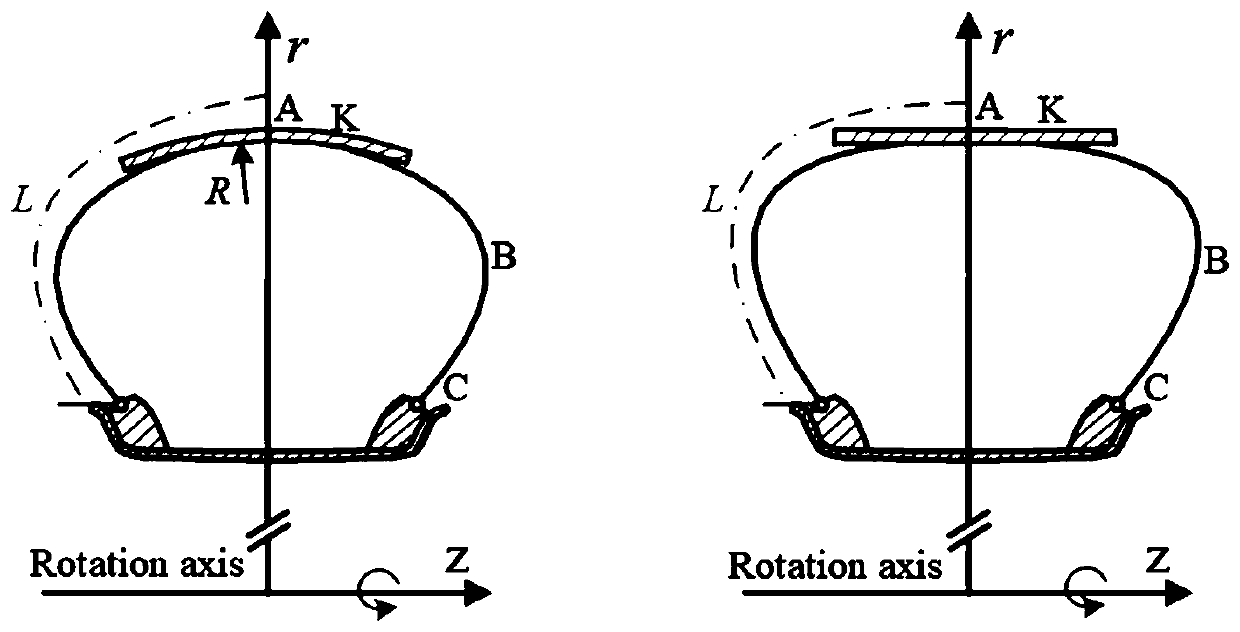

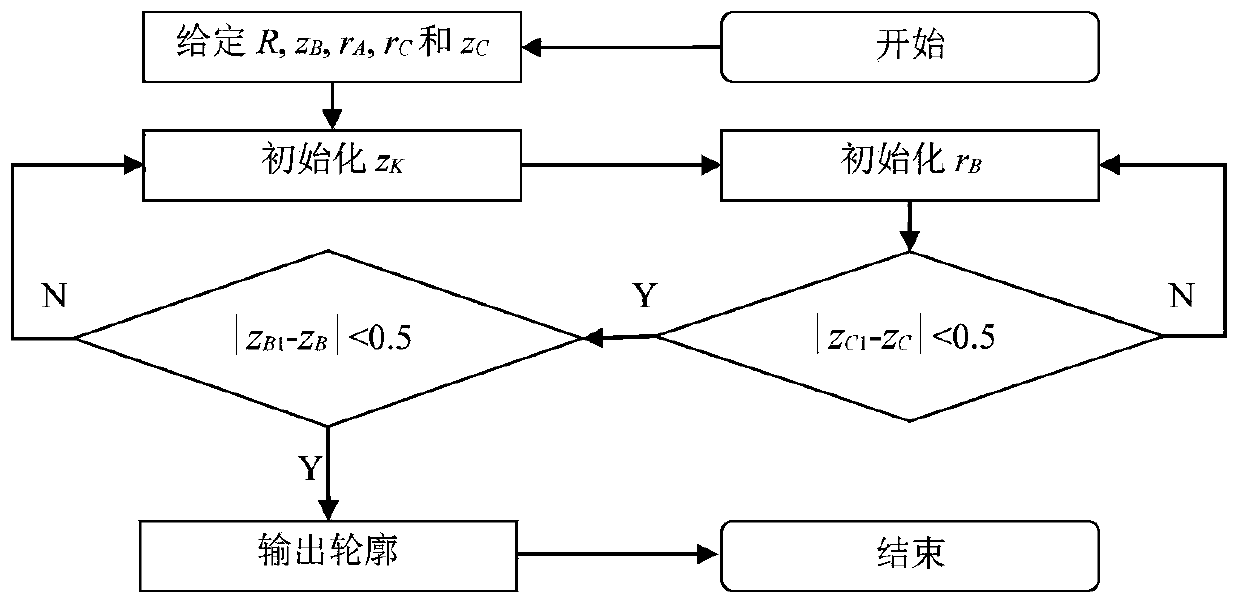

[0033] The material distribution diagram of the initial design of the tire is as follows: Figure 4 As shown, it is completed in the AutoCAD geometric drawing software, and the mesh is manually divided in the AutoCAD software, and the meshed tire geometry is imported into the tire-specific pre-processing software TYABAS 3.0 developed by Harbin Institute of Technology. Boundary conditions are set, mainly including the ground contact boundary (the boundary between the tire and the road surface), the inner surface boundary (the boundary of the inflation pressure inside the tire), and the rim contact boundary (the boundary between the tire and the rim). Set the tire material properties, the rubber material adopts the linear elastic constitutive model, the element type is C3D8R, the steel wire material is simulated using the Rebar element, and the linear elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com