Thermal relay

A thermal relay and installation box technology, applied in the field of thermal relays, can solve the problems of long heat transfer, can only be used as overload protection, thermal relays cannot be short-circuit protection, etc., to shorten the on-off response time, reduce mutual Interfering, increasing sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

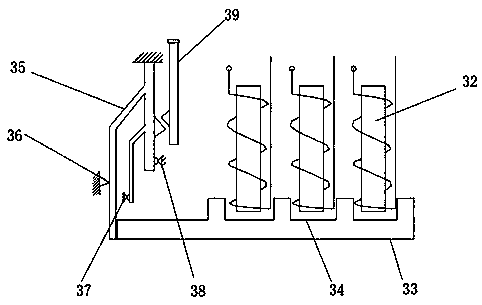

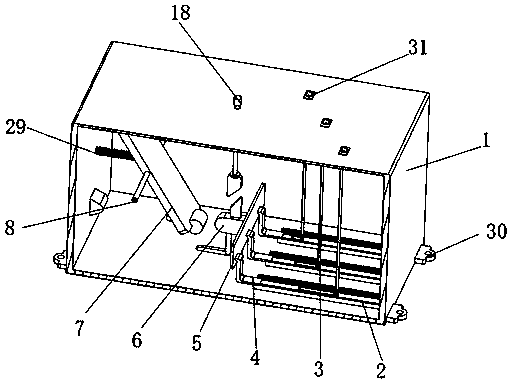

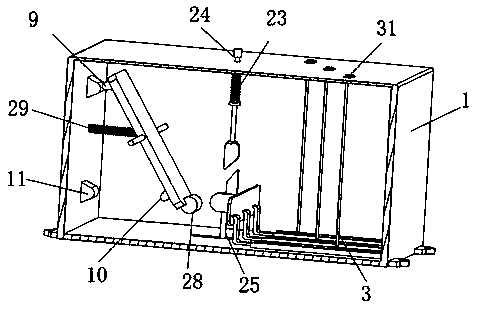

[0027] Specific implementation method: After the load is heated, the metal measuring piece 3 is driven to be heated and deformed. Since the bottom of the metal measuring piece 3 is connected to the fixed connecting plate 15, the metal measuring piece 3 is deformed and drives the fixed connecting plate 15 to slide along the slide rail groove 2 , because the fixed connecting plate 15 is in contact with the conical disc 14, and the conical disc 14 is connected with the telescopic rod 12 at the same time, during the sliding process of the fixed connecting plate 15, the conical disc 14 and the telescopic rod 12 are pushed, and the metal measuring pieces 3 respectively arranged in three groups In between, the heat interference phenomenon of the metal measuring piece 3 is reduced. At the same time, when a group of metal measuring pieces 3 are heated, the metal measuring piece 3 can still push the fixed plate 5 to ensure the working accuracy of the thermal relay. 12 After pushing the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com