A Transformer On-Load Tap-Changer Inspection and Maintenance Operation Platform

A technology of on-load tapping and operating console, which is applied in the field of operating console, can solve problems such as operation quality risk and low efficiency of equipment maintenance, and achieve the effects of shortening maintenance time, avoiding delay or change of power outage time, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

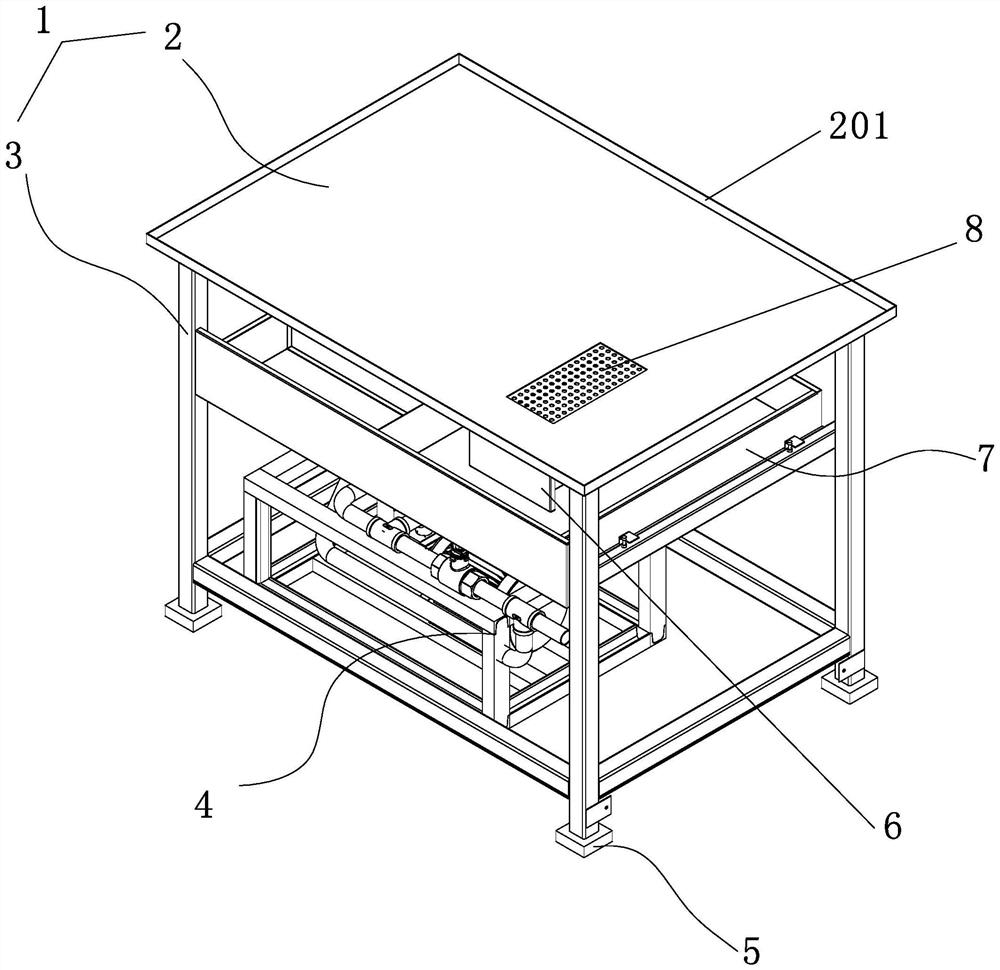

[0041] Such as figure 1 , figure 2 , image 3 In the shown embodiment 1, a transformer on-load tap-changer maintenance operation platform includes an operation platform body 1, and the operation platform body 1 includes an operation platform 2 and a support frame body 3, and the operation platform 2 is provided with waste oil The collection module, the waste oil collection module includes a filter screen 8 arranged on the operation table 2, a waste oil collector 6 slidably connected to the bottom of the operation table 2, wherein the waste oil collector 6 is installed under the filter screen 8; the oil change module 4 , the oil change module 4 is used to clean the device to be overhauled, and the oil change module 4 is fixed on the supporting frame body 3; At the bottom, the motion sensing module 5 includes a ground terminal, a pressure sensor for calculating the load.

[0042]In this technical solution, the console body 1 is used to carry the device to be overhauled, the ...

Embodiment 2

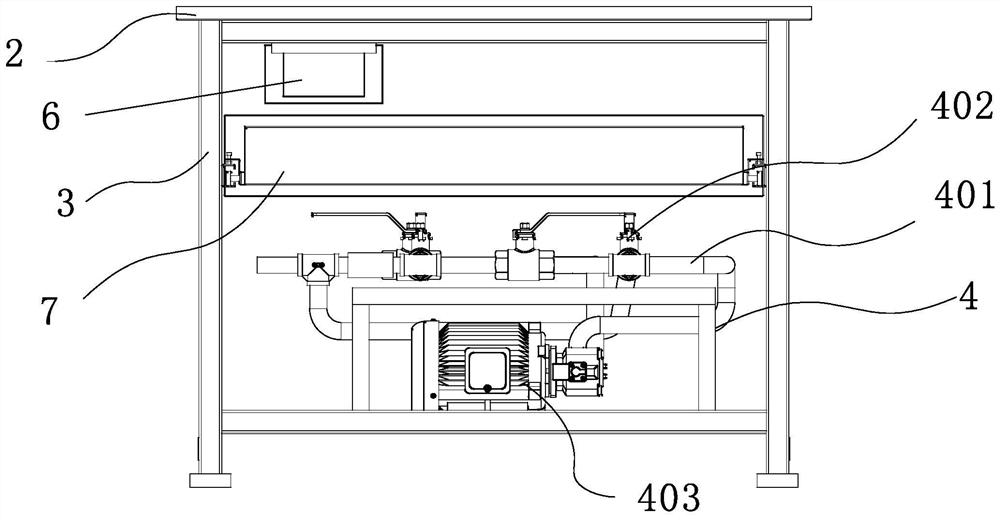

[0047] Such as Figure 5 As shown, the technical solution of embodiment 2 is basically the same as the technical solution of embodiment 1, the difference is that: the oil change module 4 includes a pipeline 401, a pipeline joint for communicating with the pipeline 401, and a switch for controlling oil circuit switching The valve 402, the centrifugal pump 403 and the flow rate controller of the centrifugal pump 403 are controlled, and the pipeline 401 is provided with a first port 405 and a second port 406 respectively. The setting of the oil change module 4 eliminates the work of on-site oil change flushing and replacement of the oil discharge pipe, making the oil change more portable. When the oil change module 4 is used, according to the actual work needs on site, the oil change module is started after the oil pipe of the device to be cleaned is connected 4, drain the remaining oil in the device and flush it with new oil. During this process, the control valve 402 controls t...

Embodiment 3

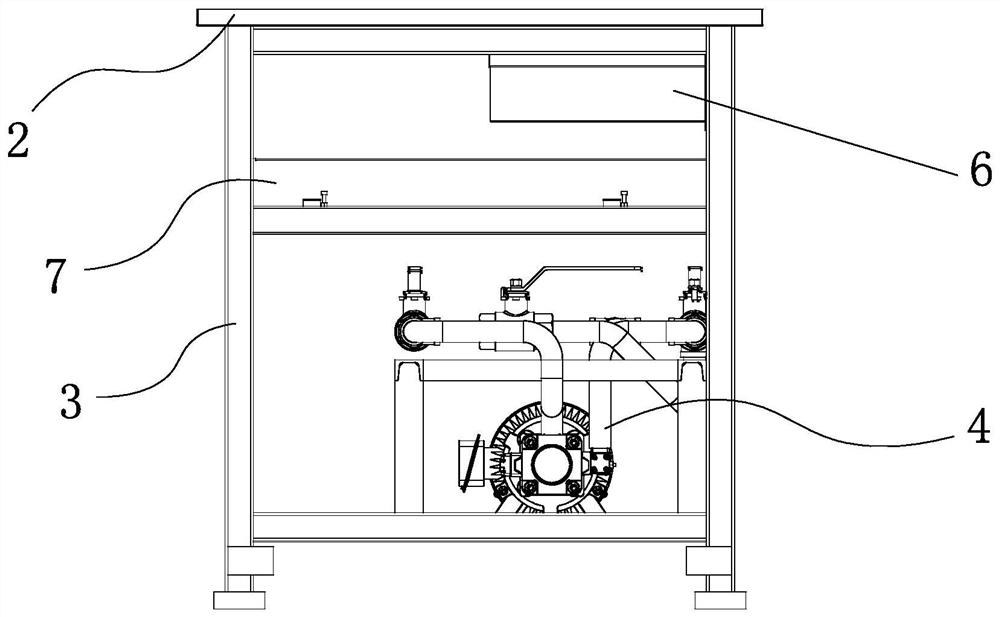

[0051] Such as Figure 4 As shown, the technical solution of embodiment 3 is basically the same as the technical solution of embodiment 1, the difference is that: a transformer on-load tap changer inspection console also includes a storage box 7, and the storage box 7 includes a tool slot 701 and The parts groove 702, the storage box 7 is slidably connected on the support frame body 3, the storage box 7 can be pulled out to take or place the tool parts, and when not in use, the storage box 7 is slid into the support frame body 3, which is convenient storage, saving space; the tool slot 701 is used to place maintenance tools, and the parts slot 702 is used to place maintenance parts, which avoids the mixing of maintenance tools and parts and affects work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com