A method for controlling the stroke action of an electron gun isolating valve

An action control, electron gun technology, applied in electron beam welding equipment, valve devices, manufacturing tools, etc., can solve the problems of gun isolation valve stuck, control motor burnout, etc., to extend service life, prolong service life, and easy to maintain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for controlling the stroke action of an electron gun gun isolation valve, characterized in that it comprises the following steps:

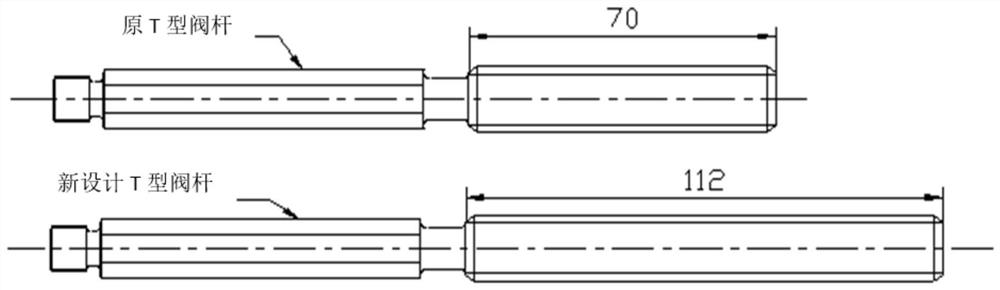

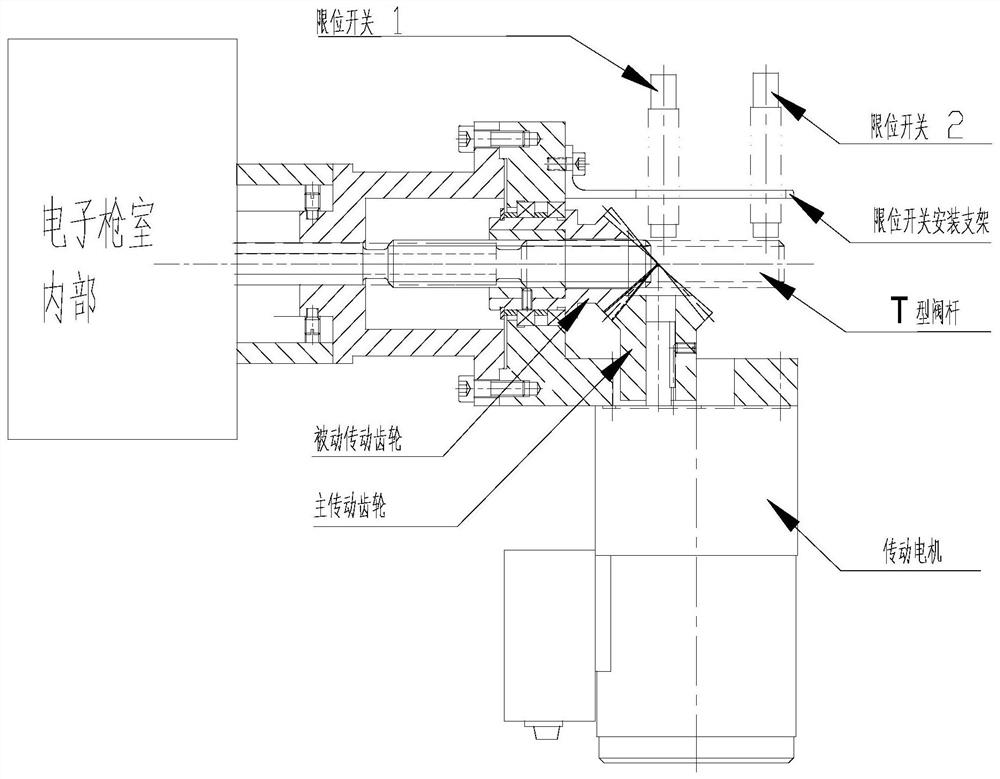

[0025] 1) According to the actual installation position of the gun isolating valve of the electron gun on site, without changing the original installation frame around the gun isolating valve, check the maximum amount that the valve stem of the gun isolating valve can be extended (the valve stem can extend up to 42mm) , redesign the T-shaped valve stem with thread length to meet the mechanical travel needs. Such as figure 1 As shown, the newly designed T-shaped valve stem is compared with the original valve stem: the T-shaped threaded part is 42mm longer than the original one, and the rest of the T-shaped valve stem structure remains unchanged. At the same time, design a fixed bracket that can hold two travel control detection limit switches, such as figure 2 shown. Compared with the original switch bracket, the new detection l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com