Continuous label printing machine operated on surface of insole

A marking machine and insole technology, applied in printing, stamping, etc., can solve problems such as low work efficiency and frequent operations, and achieve the effects of improving practicability, ensuring the effect of marking, and ensuring the quality of marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

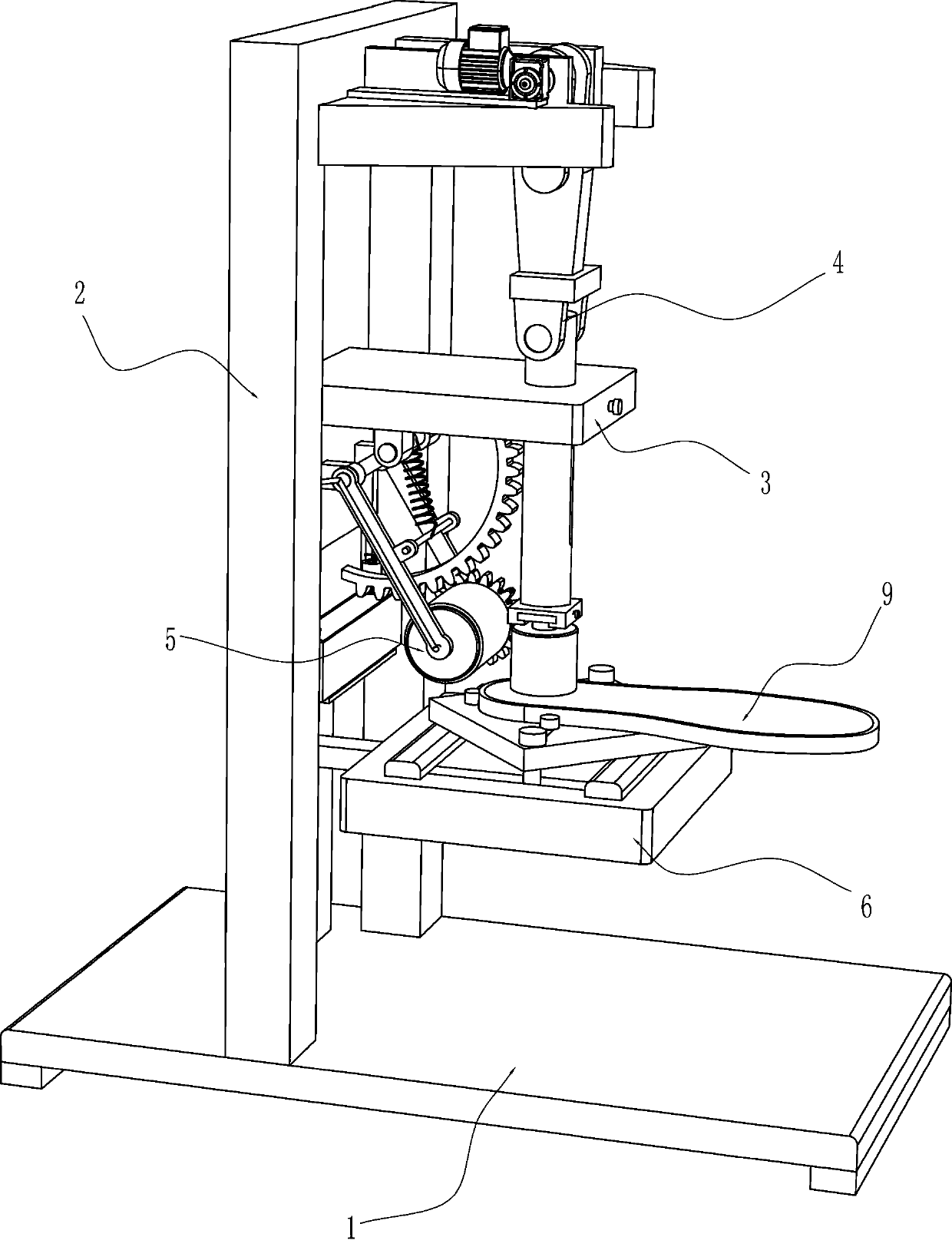

[0023] A continuous marking machine on the surface of insoles, such as Figure 1-4 As shown, it includes a base 1, a frame 2, an L-shaped mounting frame 3, a marking mechanism 4 and a feeding mechanism 5, the top of the base 1 is connected with a frame 2, and the middle part of the frame 2 is provided with an L-shaped mounting frame 3. The marking mechanism 4 is installed on the frame 2 top, and the L-shaped installation frame 3 is provided with a feeding mechanism 5, and the marking mechanism 4 and the feeding mechanism 5 contact and cooperate.

[0024] Marking mechanism 4 comprises decelerating motor 41, fork 42, sliding column 43, connecting rod 44 and marking mold 45, and frame 2 top is equipped with decelerating motor 41 by the mode of bolt connection, and the output shaft of decelerating motor 41 is connected There is a swing bar 42, and the L-shaped installation frame 3 is slidably provided with a slide column 43, the slide column 43 is vertically arranged, and a connec...

Embodiment 2

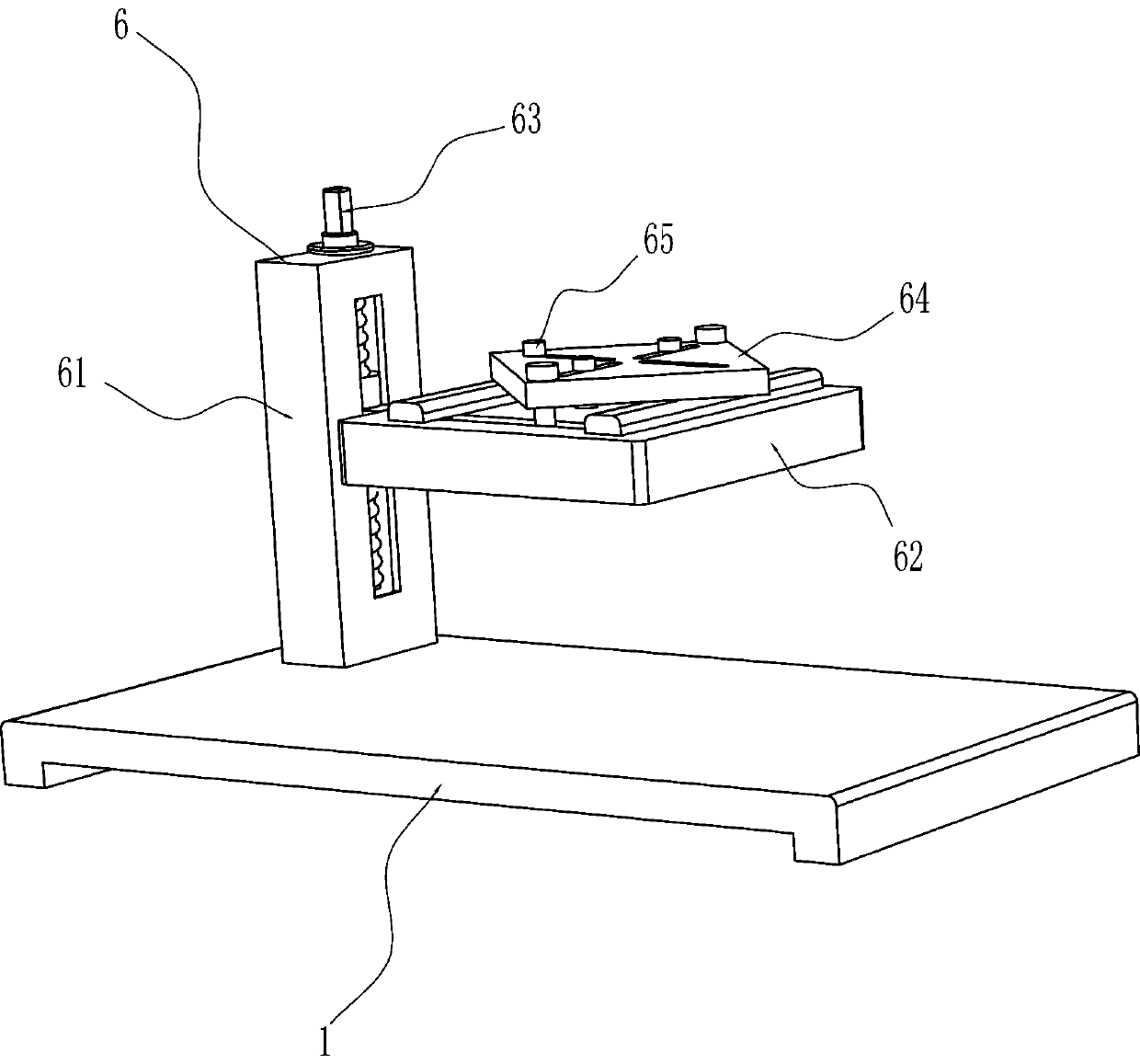

[0028] On the basis of Example 1, as Figure 5 As shown, a support assembly 6 is also included. The support assembly 6 includes a support frame 61, a support platform 62, an adjustment screw 63, a positioning plate 64 and a positioning column 65, and the top left side of the base 1 is connected with a support frame by means of bolts. 61, the support frame 61 is slidably provided with a support platform 62, the support frame 61 is rotatably connected with an adjustment screw 63, the adjustment screw 63 is threaded with the support platform 62, and the support platform 62 is connected with a positioning plate 64 in a detachable manner , The positioning plate 64 is provided with three positioning columns 65 with adjustable distances.

[0029] When the insole 9 is marked, the insole 9 is placed on the positioning plate 64 and positioned at the inside of the three positioning columns 65, so that the positioning plate 64 and the positioning columns 65 can position and support the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com