Seal gasket element for a mixing apparatus and method for obtaining and applying the same

A technology for sealing components and gaskets, which is applied to household components, engine sealing, chemical instruments and methods, etc., can solve the problems of technical labor and high manufacturing costs, and achieve the effect of quick and easy application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

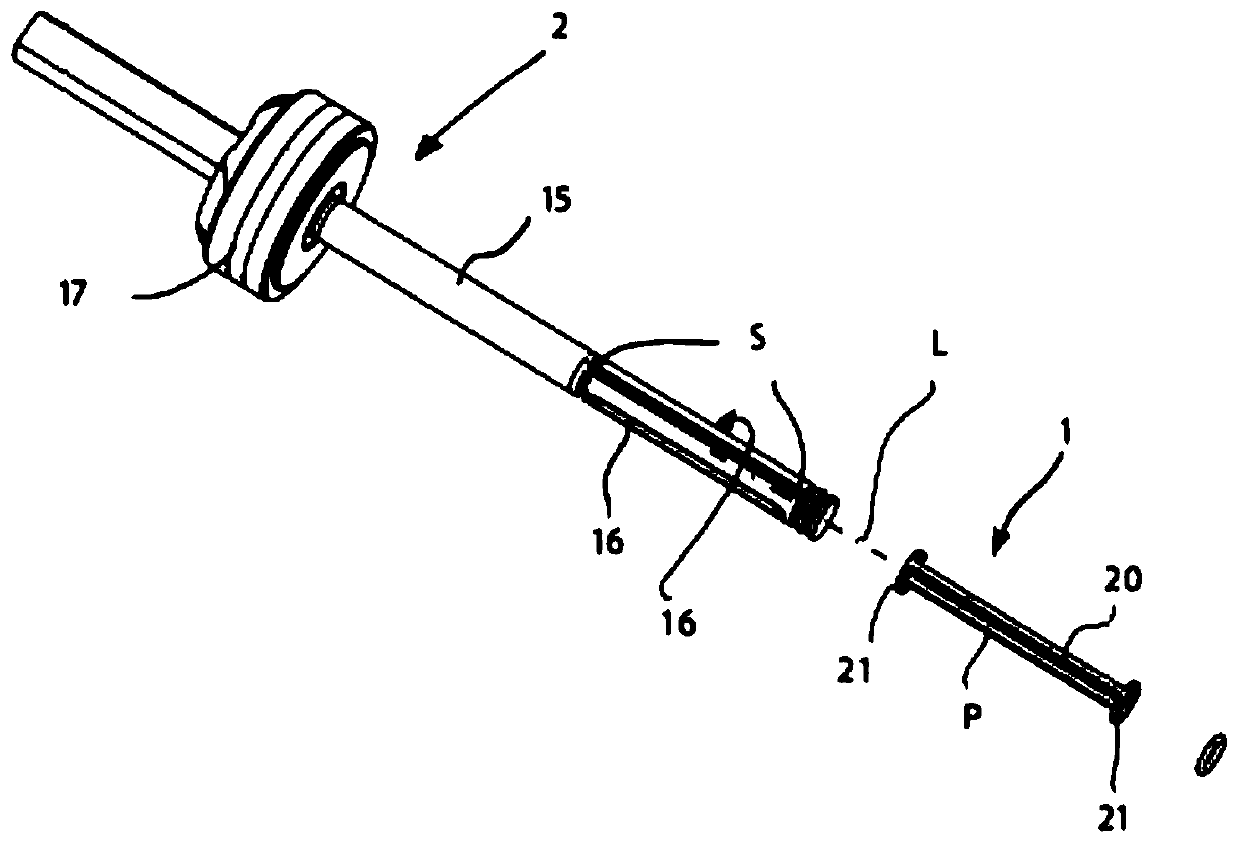

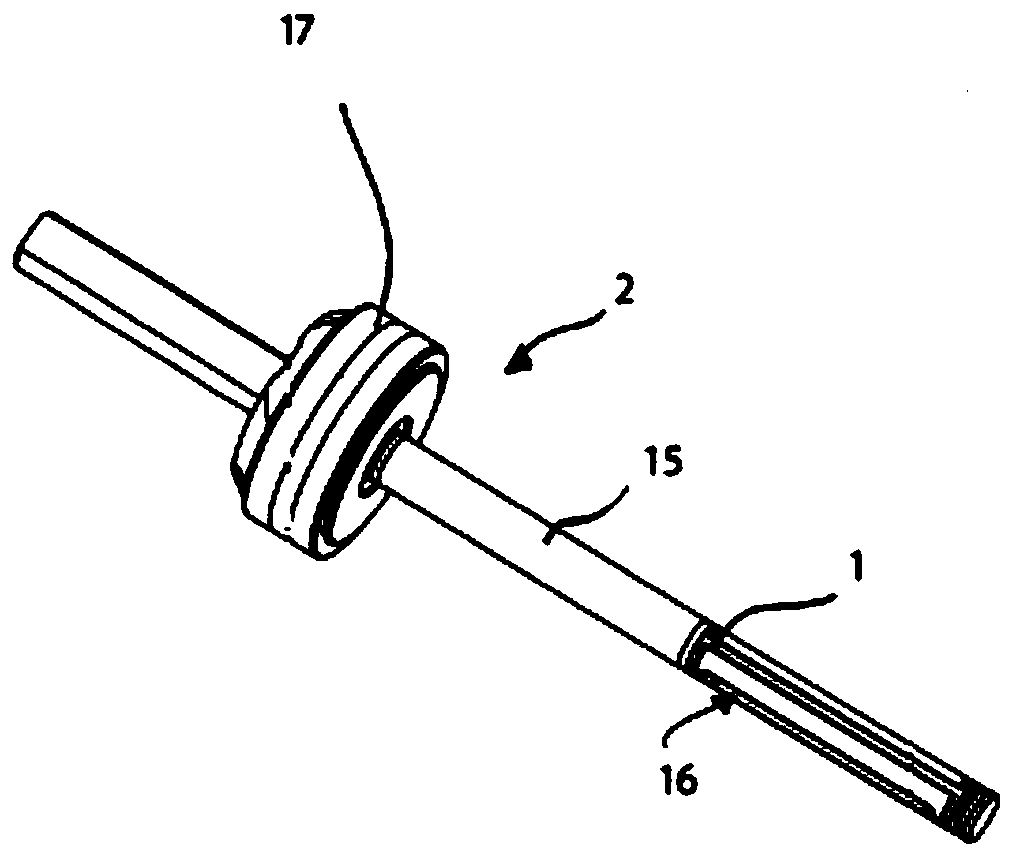

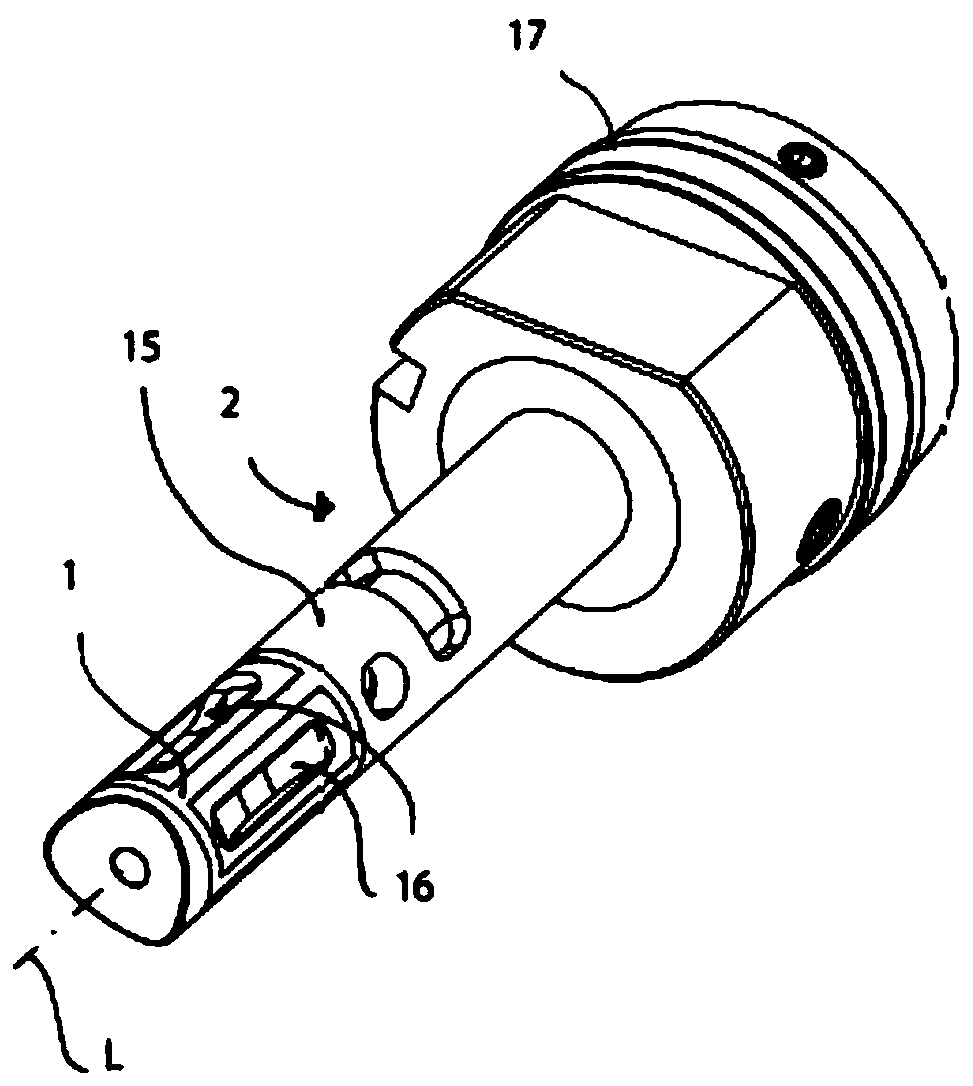

[0111] With reference to the drawings, according to the invention there is described a sealing gasket element 1 to be mounted on a sliding member 2 of a mixing device M, more precisely to be mounted for mixing chemically reactive polymer components for use in On the slide valve 2 of the mixing device M that obtains the mixture to be injected or poured into the mould.

[0112] The mixture may especially be a polyurethane mixture obtained from a first polymer component and at least a second polymer component such as polyol or isocyanate, or a mixture, or epoxy novolac or polyester or vinyl ester or silicone , which consists of at least one reactive resin and at least one reactive curing component.

[0113] It will be apparent from the following description that the invention is directed to a sealing system consisting of a slide valve 2 of a mixing device M and of a sealing gasket element 1 (which is manufactured separately from the slide valve 2) so as to have The mesh structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com