An oil storage tank oil inlet device

An oil storage tank and oil inlet technology, which is applied in packaging, transportation and packaging, and large containers, etc., can solve the problem of large friction area between oil products and gas in the oil storage tank, strong impact force on the side plate of the oil storage tank and the floating plate, Problems such as large oil evaporation can reduce the risk of chucking and sinking, reduce investment, and reduce the frictional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

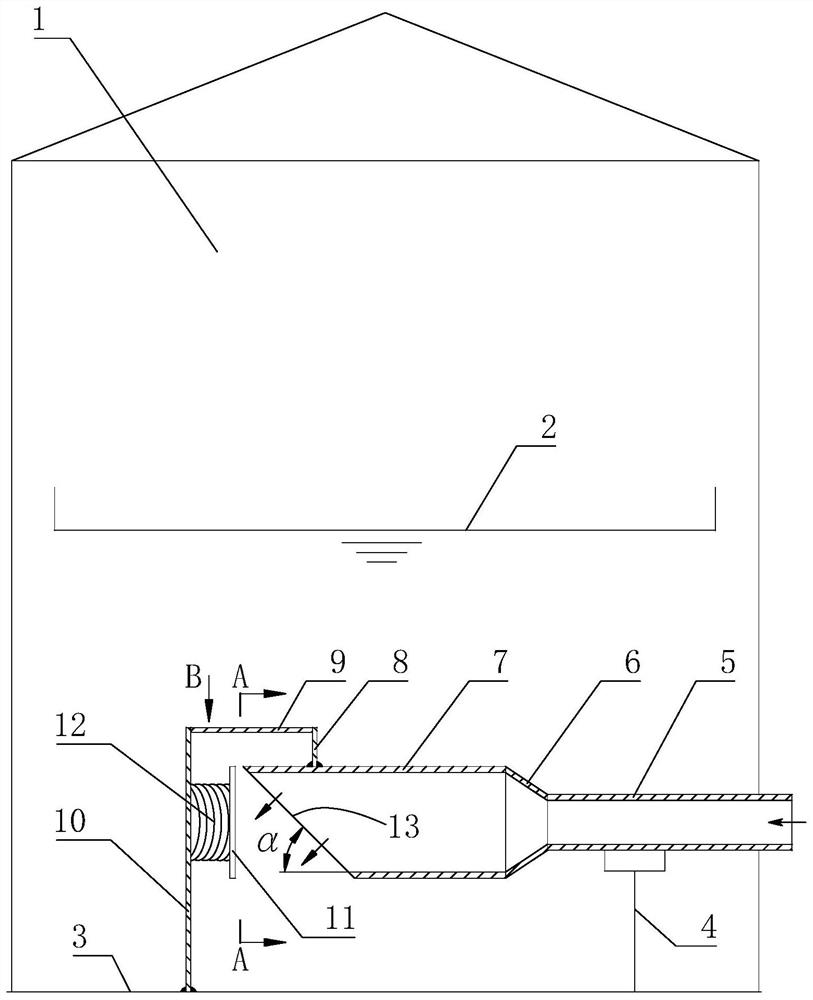

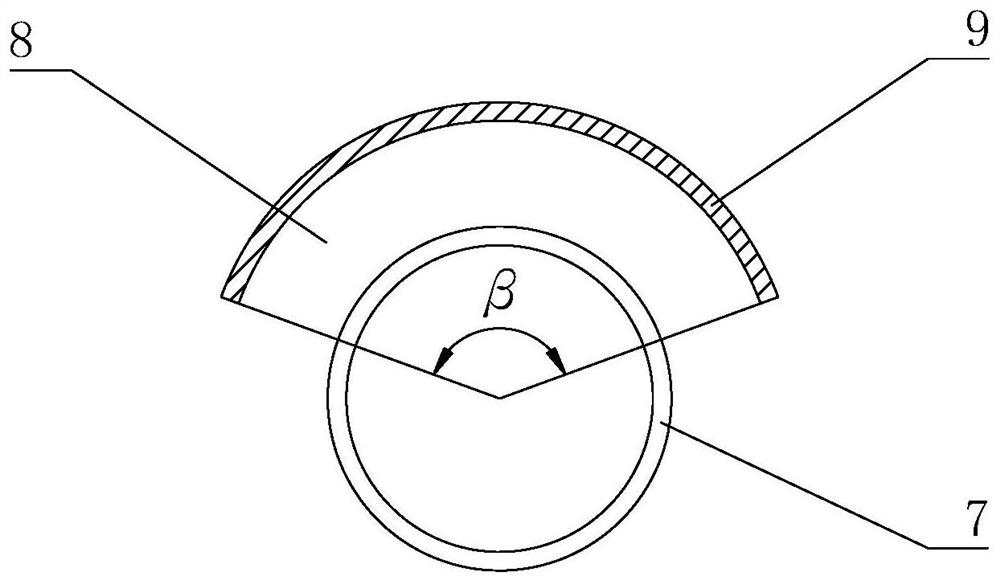

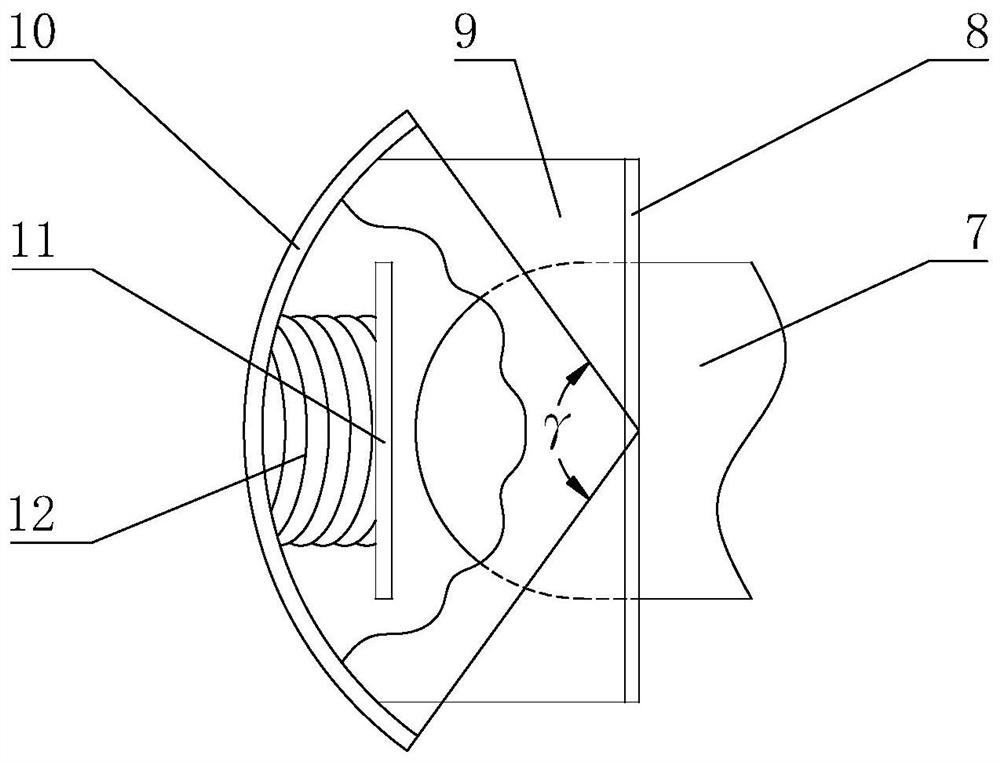

[0012] see figure 1 , figure 2 with image 3 , The oil inlet device of the oil storage tank of the present invention is arranged in the oil storage tank 1, and the oil storage tank 1 is a vertical steel oil storage tank with a floating plate 2. The oil inlet device of the oil storage tank includes a horizontally arranged oil inlet pipe 5 and a diameter-expanding pipe 7; The oil inlet pipeline 5 is connected with the expansion pipe 7 through a small head 6, and the outlet of the expansion pipe 7 is an oil outlet 13. The cross-sectional shape of the oil inlet pipeline 5 and the expansion pipe 7 is circular, and can be coaxially arranged (such as figure 1 Shown), can also be different axis settings (figure omitted). The inner diameter of the expanding pipe 7 is generally 1.5 to 3 times the inner diameter of the oil inlet pipeline 5 .

[0013] Such as figure 1 As shown, the oil outlet 13 is arranged obliquely downward relative to the horizontal plane. The angle α between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com