Anti-counterfeit label making robot assembly line based on expansion and stretching

A technology of anti-counterfeiting labels and robots, which is applied in the field of anti-counterfeiting label production robot assembly line, can solve the problems of not being able to distinguish the authenticity and affect the recognizability of anti-counterfeiting labels, and achieve the elimination of overlapping, better anti-counterfeiting effect and improved recognizability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

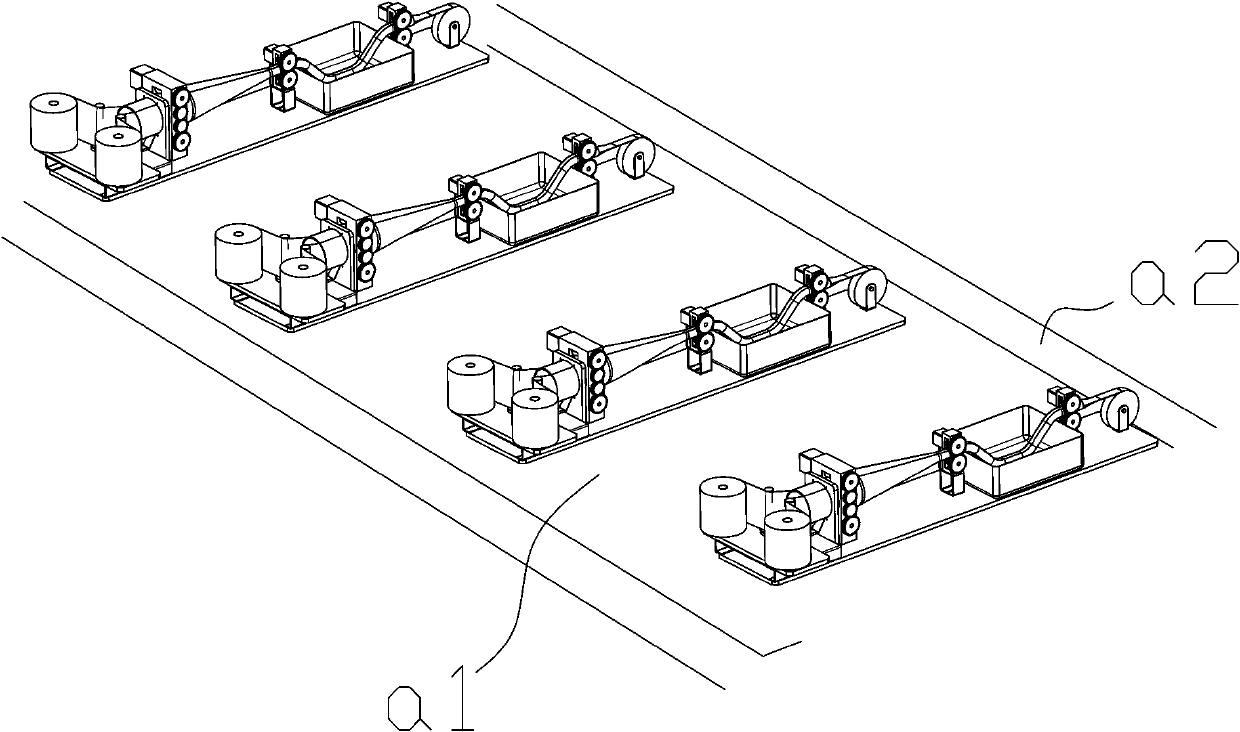

[0026] Such as Figure 1 to Figure 8 As shown, the anti-counterfeiting label production robot assembly line based on expansion and stretching described in this embodiment includes a base platform a1, and a plurality of label production robots are arranged on the base platform, and the output of the multiple label production robots is One side is provided with a conveyor belt a2.

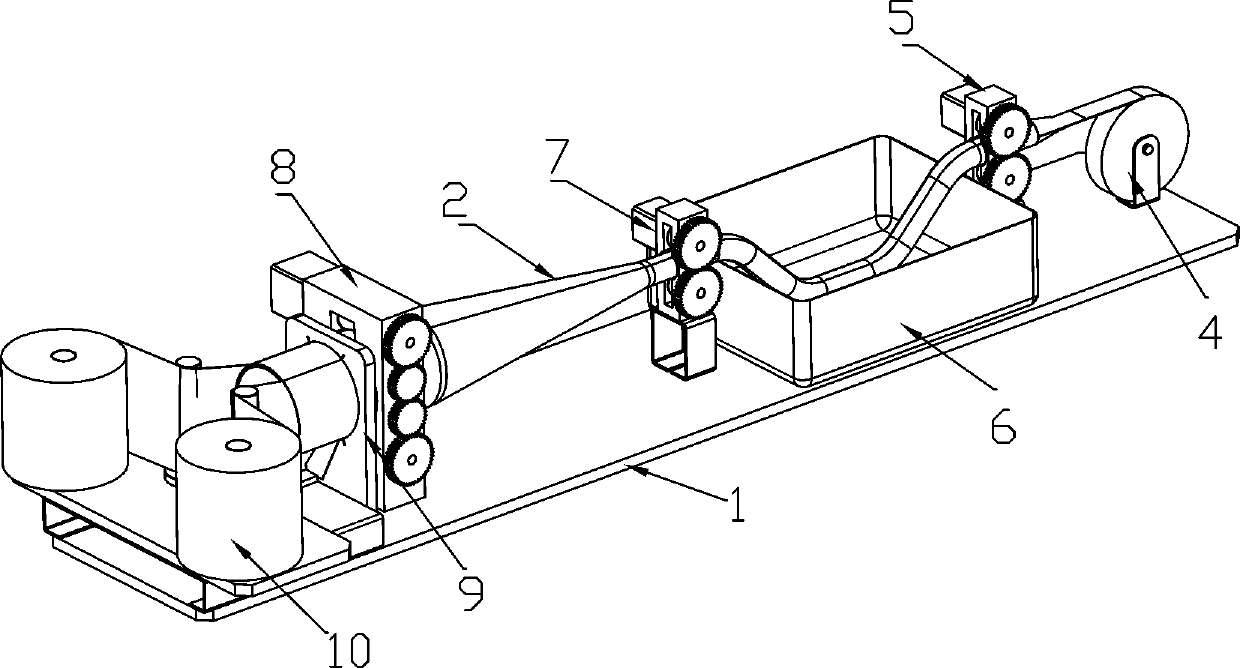

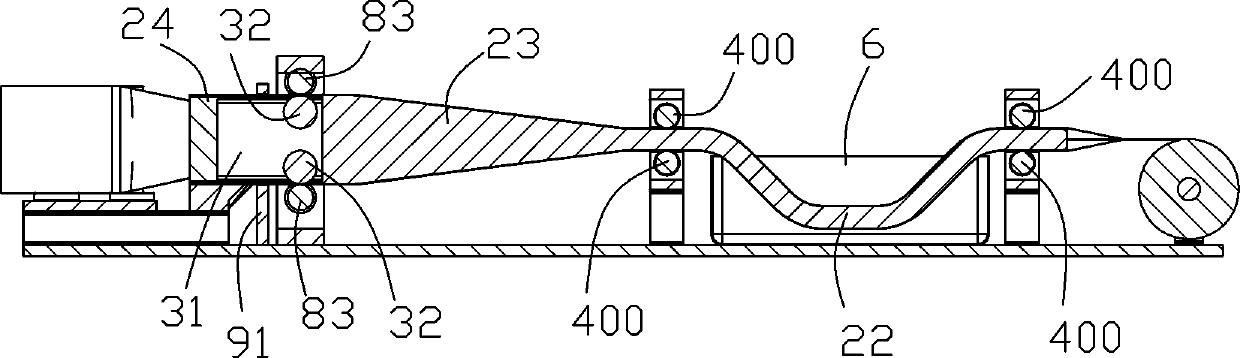

[0027] , each tab makes a bot:

[0028] It includes a bottom plate 1, an expansion mandrel 2, an internal expansion stretching mechanism 3, and a stretch film roll 4 sequentially arranged on the bottom plate 1, a primary pulling mechanism 5, a particle attachment groove 6, a secondary pulling mechanism 7, an outer Expansion and stretching mechanism 8, film layer cutting mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com