Efficient evaporator of separated gravity assisted heat pipe

A gravity heat pipe, separated technology, applied in the field of heat pipes, can solve the problems of large size, large surface area, large difference in condensate mass flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Below in conjunction with the embodiment of accompanying drawing, the present invention will be further described:

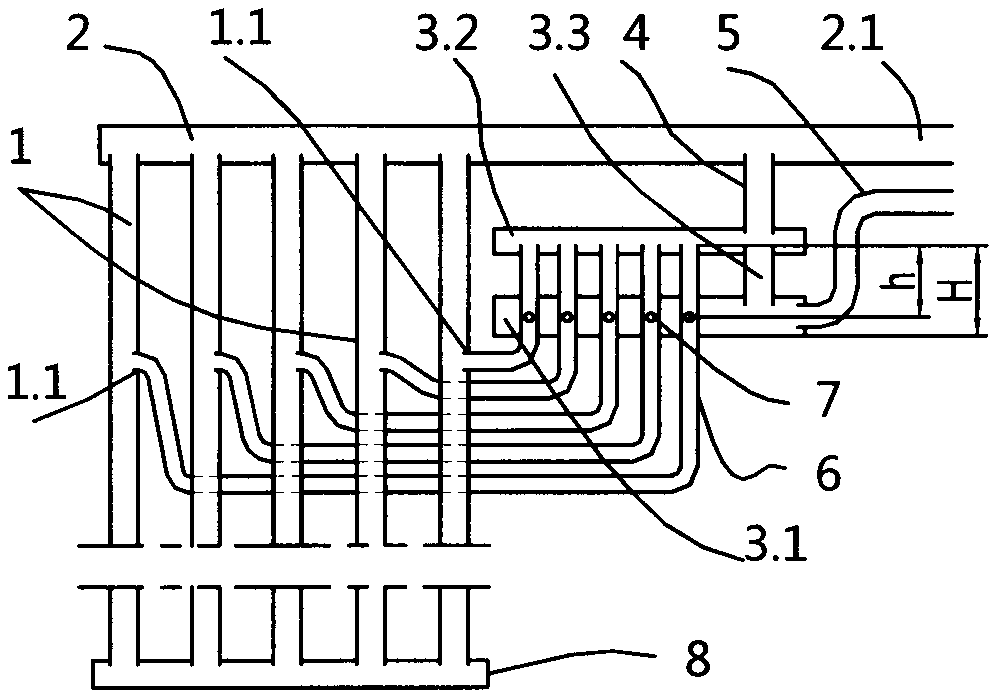

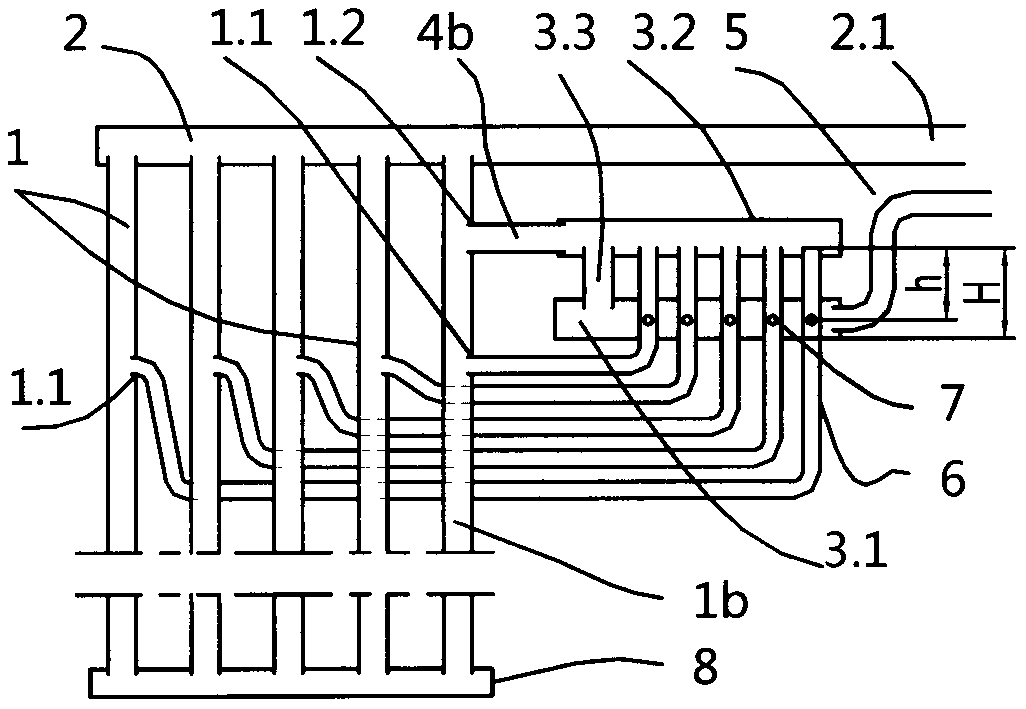

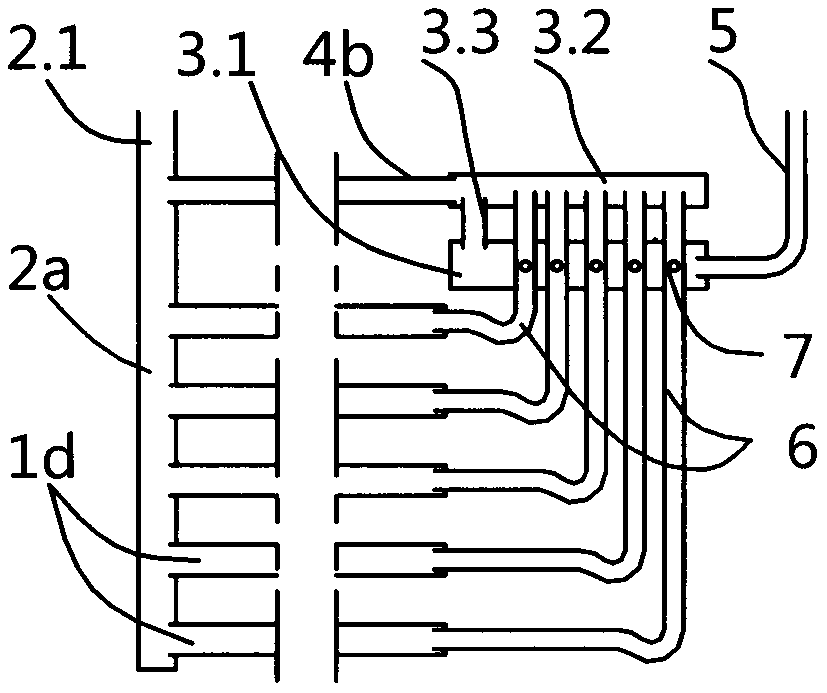

[0089] attached figure 1 It is the first embodiment of the present invention, one of the first preferred pipeline principles of the technical solution: including a horizontal steam header 2, including two or more vertical or oblique evaporation tubes 1, A condensate inlet pipe 5; one end of the steam header 2 is sealed and the other end is provided with a steam outlet 2.1; the lower wall of the steam header 2 is provided with a through hole to facilitate the communication between the evaporation pipe 1 and the flash conduit 4; The upper tube wall of the evaporating tube 1 is provided with a liquid inlet hole 1.1, and the upper nozzles of the evaporating tube 1 are connected with the steam manifold 2; the lower nozzles of the evaporating tube 1 are connected with the lower connecting pipe 8; the key is: The uniform distribution of condensate is completed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com