A positioning guide mechanism for cable production and processing

A technology for positioning and guiding cables, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc. It can solve the problems of cable production and processing, cable shaking, etc., and achieve the effect of weakening the shaking force and ensuring stable guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

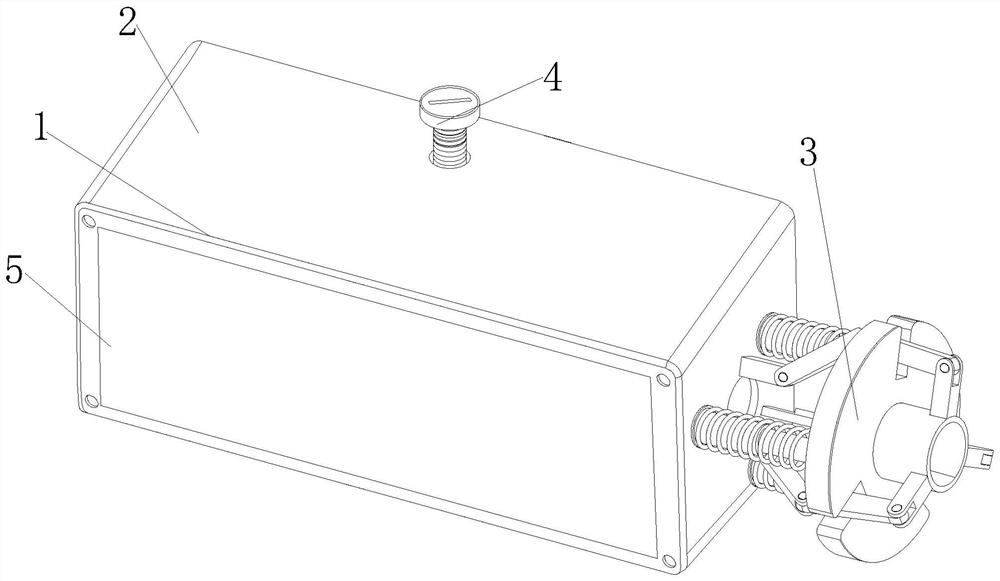

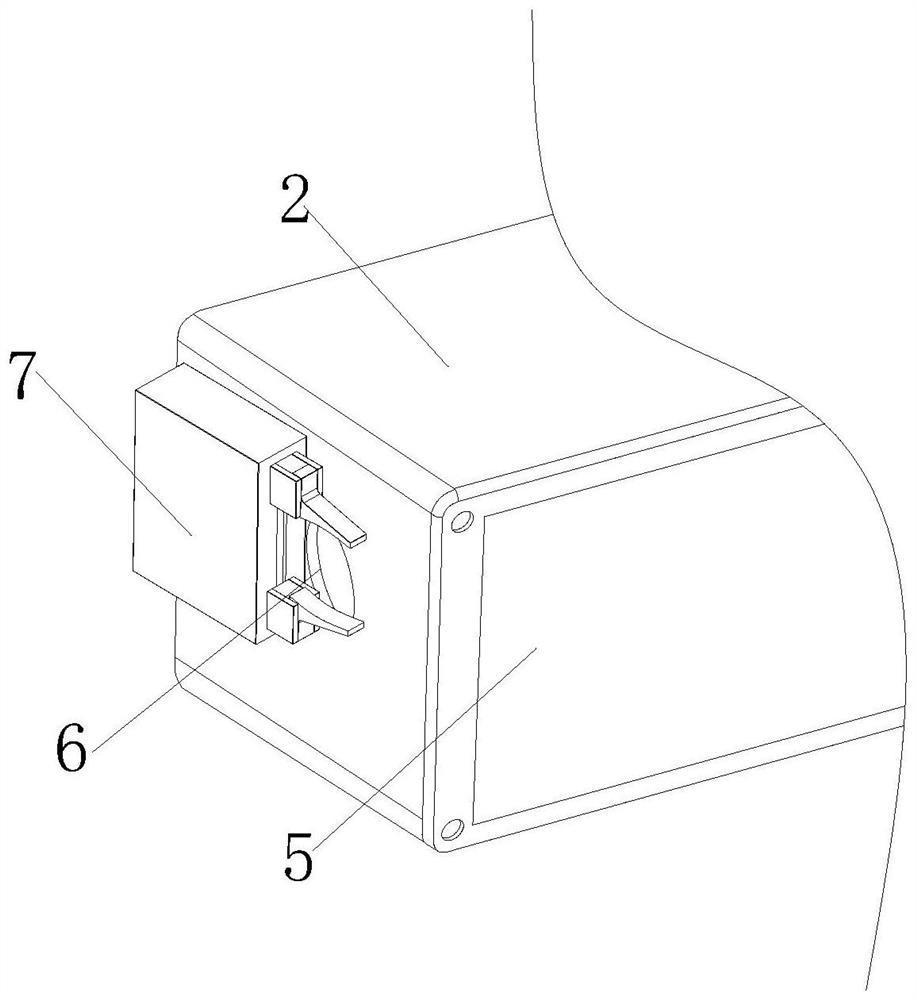

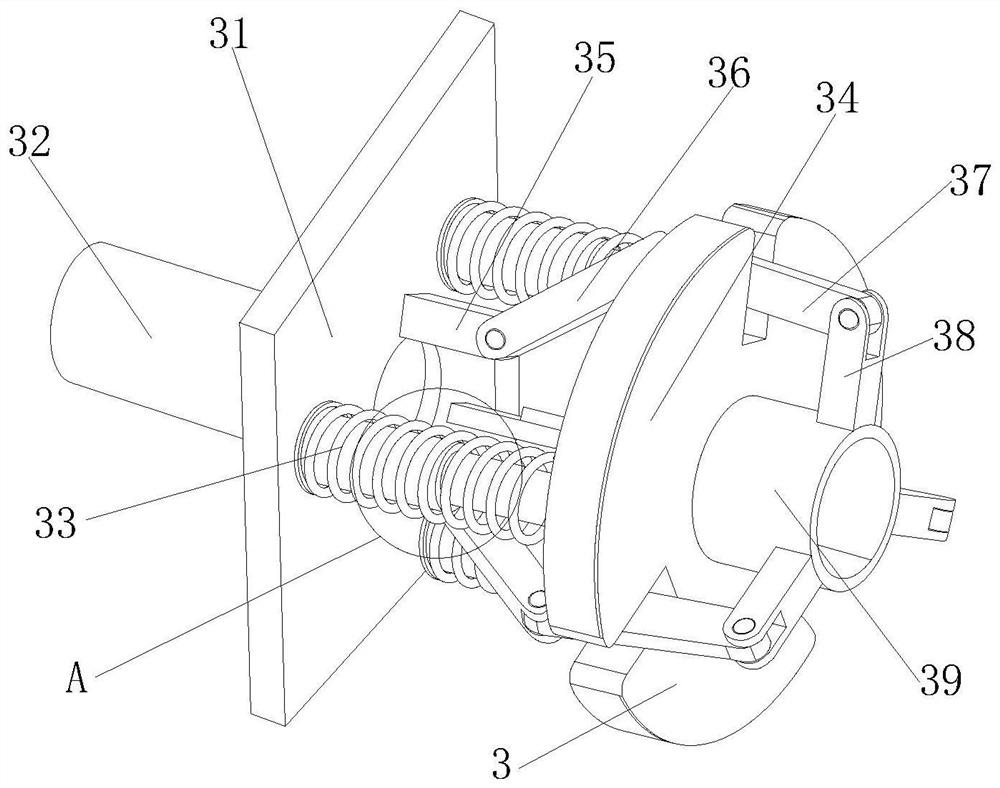

[0027] see figure 1 with figure 2 , a positioning guide mechanism for cable production and processing according to the present invention includes a guide body 1, and the guide body 1 includes a box body 2, an adjustment structure 3, a roller structure 4, a cover plate 5, a circular opening 6 and a positioning structure 7 , the box body 2 has a rectangular structure, the right side of the box body 2 is embedded with an adjustment structure 3 horizontally, the rear side of the inner wall of the box body 2 is locked and fixed with a roller structure 4, and the cable penetration of the adjustment structure 3 and the roller structure 4 is located at the same On the horizontal plane, the four ends of the cover plate 5 are provided with four circular grooves, and the cover plate 5 is fixed with the box body 2 through the four circular grooves by screws, and the left middle part of the box body 2 is provided with a circular opening 6, and the box body 2 The positioning structure 7 i...

Embodiment 2

[0032] In a positioning guide mechanism for cable production and processing of the present invention, there are three bearing struts 33 and three struts 35, and the angles between the three bearing struts 33 and the three struts 35 are all 120 degrees. At the same time, the three bearing struts 33 and the three poles 35 are distributed alternately, which is conducive to fully weakening the shaking force of the cable. The middle part of the inner side of the disc 34 is provided with a port, and the port, the circular pipe 32 and the cylindrical sleeve 39 On the same axis, it is beneficial to pass through the cable. There are three upper rollers 47 and four lower rollers 43, and the three upper rollers 47 and the four lower rollers 43 are distributed in a staggered manner, which is convenient for guiding the cables. The block 74 is provided with two pieces, and the two arc-shaped blocks 74 are left and right symmetrical in the middle of the frame body 71, and the center point bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com