Chip packaging structure and chip packaging method

A technology of chip packaging structure and packaging structure, which is applied in the direction of sustainable manufacturing/processing, climate sustainability, semiconductor devices, etc., can solve the problems of single function and inability to realize bidirectional sensing of image sensors, etc., so as to reduce maintenance costs and shrink The effect of device assembly size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

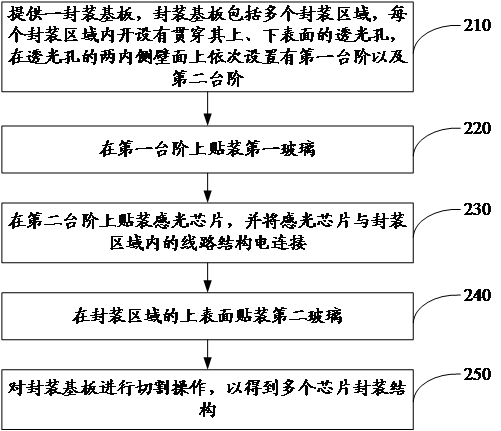

[0049] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

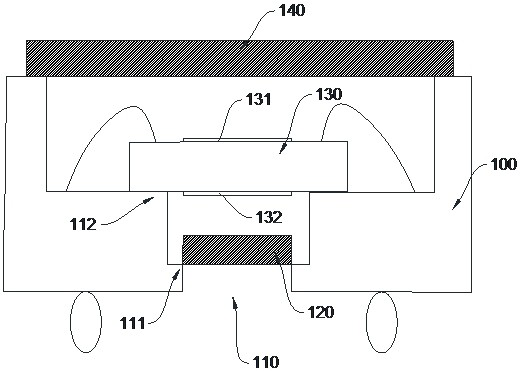

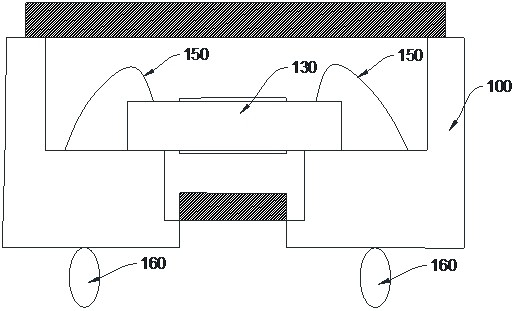

[0050] An embodiment of the present application provides a chip packaging structure, which can realize double-sided imaging of an image sensor. Figure 1~Figure 2 shows a side view of the chip package structure, as Figure 1~Figure 2 As shown, the chip package structure includes:

[0051] A substrate 100, on which there are light-transmitting holes 110 penetrating through its upper and lower surfaces, and a first step 111 and a second step 112 are sequentially arranged on both inner sidewalls of the light-transmitting hole 110;

[0052] The two first steps on the two inner wall surfaces are opposite to each other, and the two second steps on the two inner wall surfaces are opposite to each other.

[0053] A first glass 120, which is arranged on the first step 111;

[0054] A photosensitive chip 130...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com