A flat type oxygen sensor for motorcycle

An oxygen sensor, flat-panel technology, which is applied in the field of flat-panel oxygen sensors for motorcycles, can solve problems such as difficult maintenance, low yield, and difficult assembly, and achieve the effects of simple assembly process, improved service life, and stable contact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

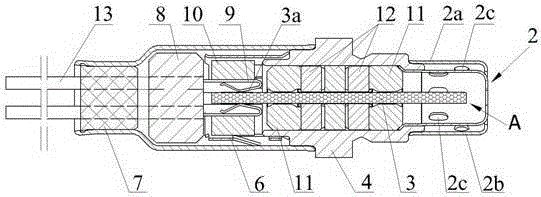

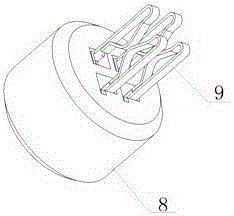

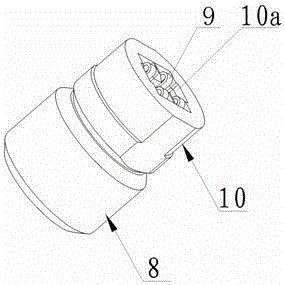

[0022] control figure 1 , the flat-plate oxygen sensor of the present invention, mainly by protective casing 5, protective tube 2, base 4, chip 3, terminal holder 8, electrode terminal 9,: insulating bushing 11, sealing member 12, sealing plug 8 and wire 13. The base 4, the protective tube 2 and the protective sleeve 5 are all made of stainless steel, wherein the protective tube 2 and the protective sleeve 5 are in the shape of a round tube, and the protective tube 2 is provided with a number of air inlets 2a and one end is closed; the protective tube 2 and the protective sleeve 5 are respectively connected to the two ends of the stainless steel base 4, and the inner cavities of the three communicate with each other to form a columnar cavity with one end open, corresponding to the one end of the protective tube as the air intake cavity A. The sealing plug 7 is made of rubber and plugged at the opening end of the cavity; the terminal holder 8, the insulating bushing 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com