A cooling box and a switchgear

A switch cabinet and box body technology, applied in substation/switch layout details, substation/switchgear cooling/ventilation, electrical components, etc., can solve problems such as overheating of electrical components, hazards of electrical components, and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

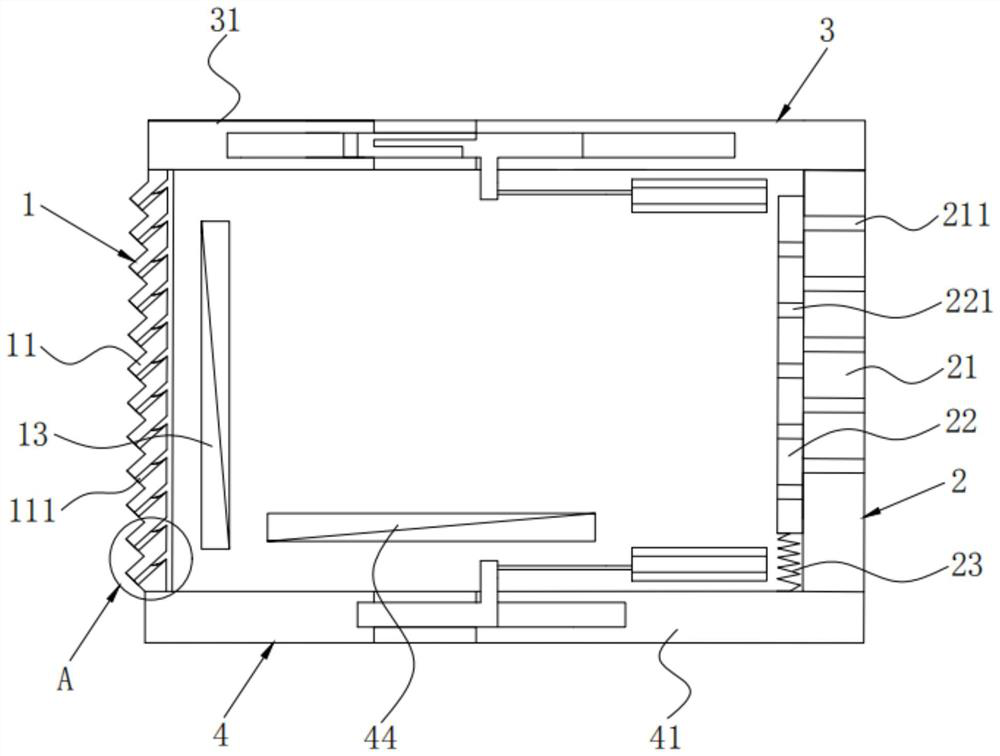

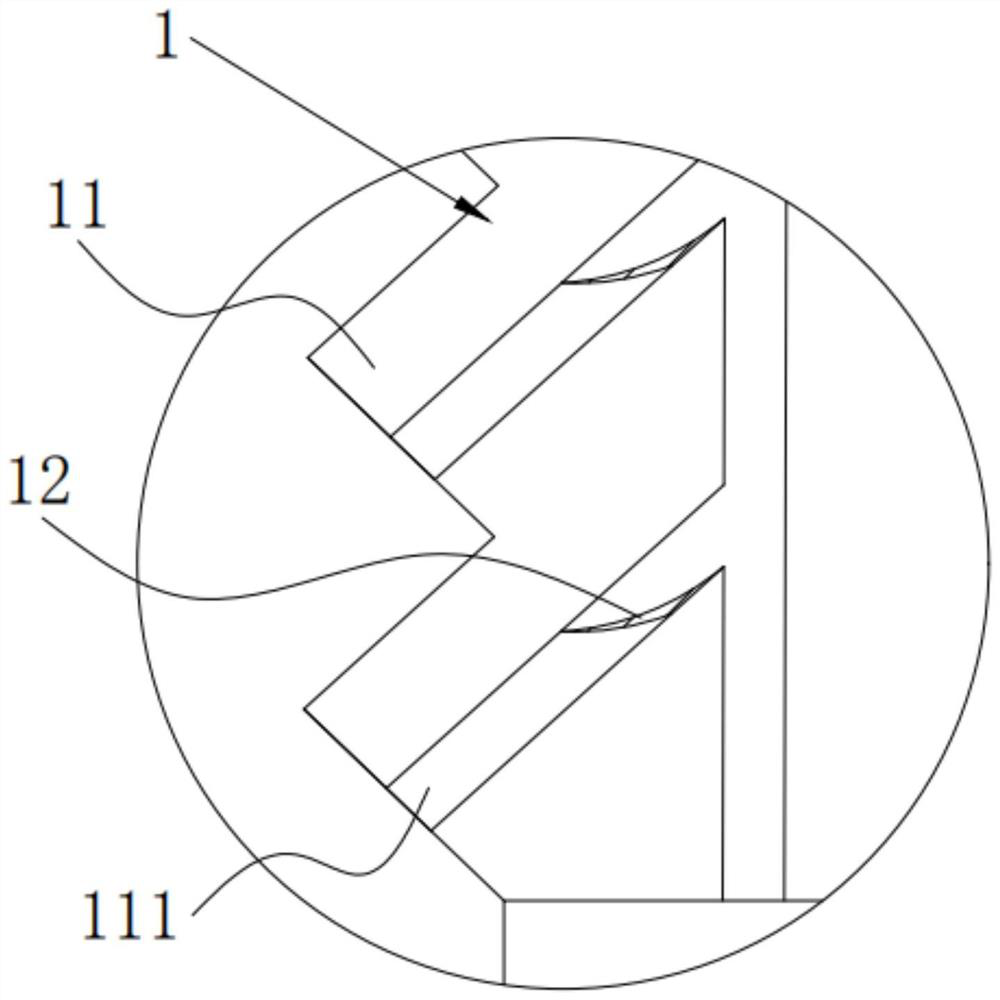

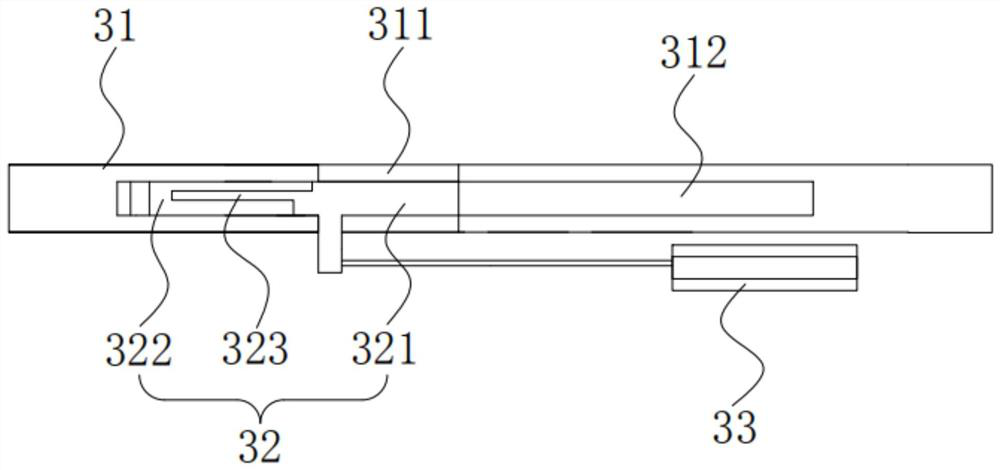

[0037] Such as Figure 1 to Figure 6 The heat dissipation box shown includes a housing, a primary heat dissipation assembly 1 and a secondary heat dissipation assembly 2; the casing is used to accommodate heat generating devices; The heat dissipation assembly 1 includes a first-level heat dissipation plate 11, and the first-level heat dissipation plate 11 is provided with a first-level heat dissipation hole 111, and the first-level heat dissipation hole 111 outputs the heat inside the housing to the outside; the second-level heat dissipation assembly 2 Installed on the housing, the secondary heat dissipation assembly 2 includes a secondary fixed plate 21, a secondary moving plate 22 and a deformation member 23, and the secondary moving plate 22 and deformation member 23 are located on the secondary fixing plate 21 On the inner side, one end of the deformation member 23 is connected to the inner wall of the housing, and the other end of the deformation member 23 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com