Method for operating tamping assembly of track construction machine, tamping device for compacting track bed, and track construction machine

A unit and machine technology, applied in the field of track construction machines, can solve problems such as time-consuming and costly control and maintenance, damage to the tamping unit, insufficient compaction of the ballast bed, etc., and achieve high reliability and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

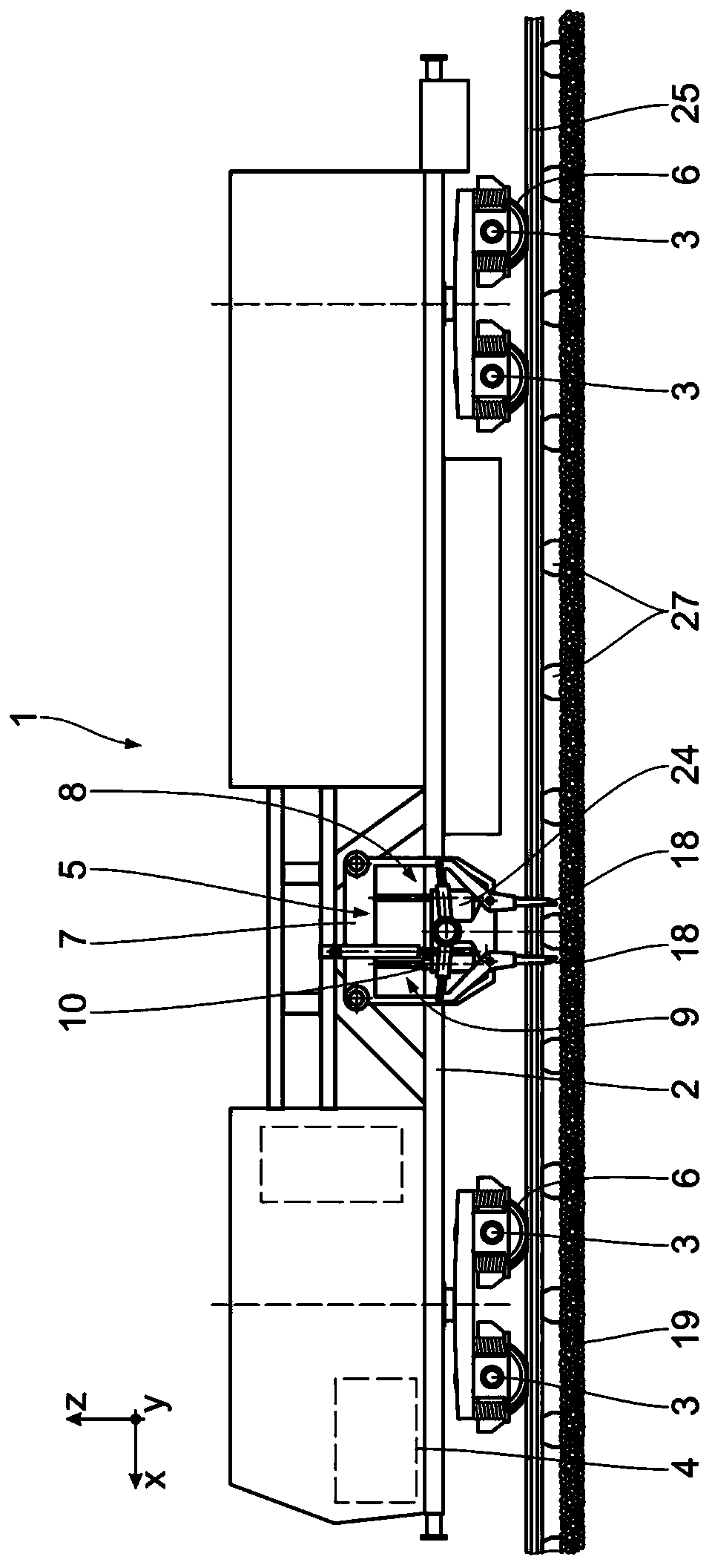

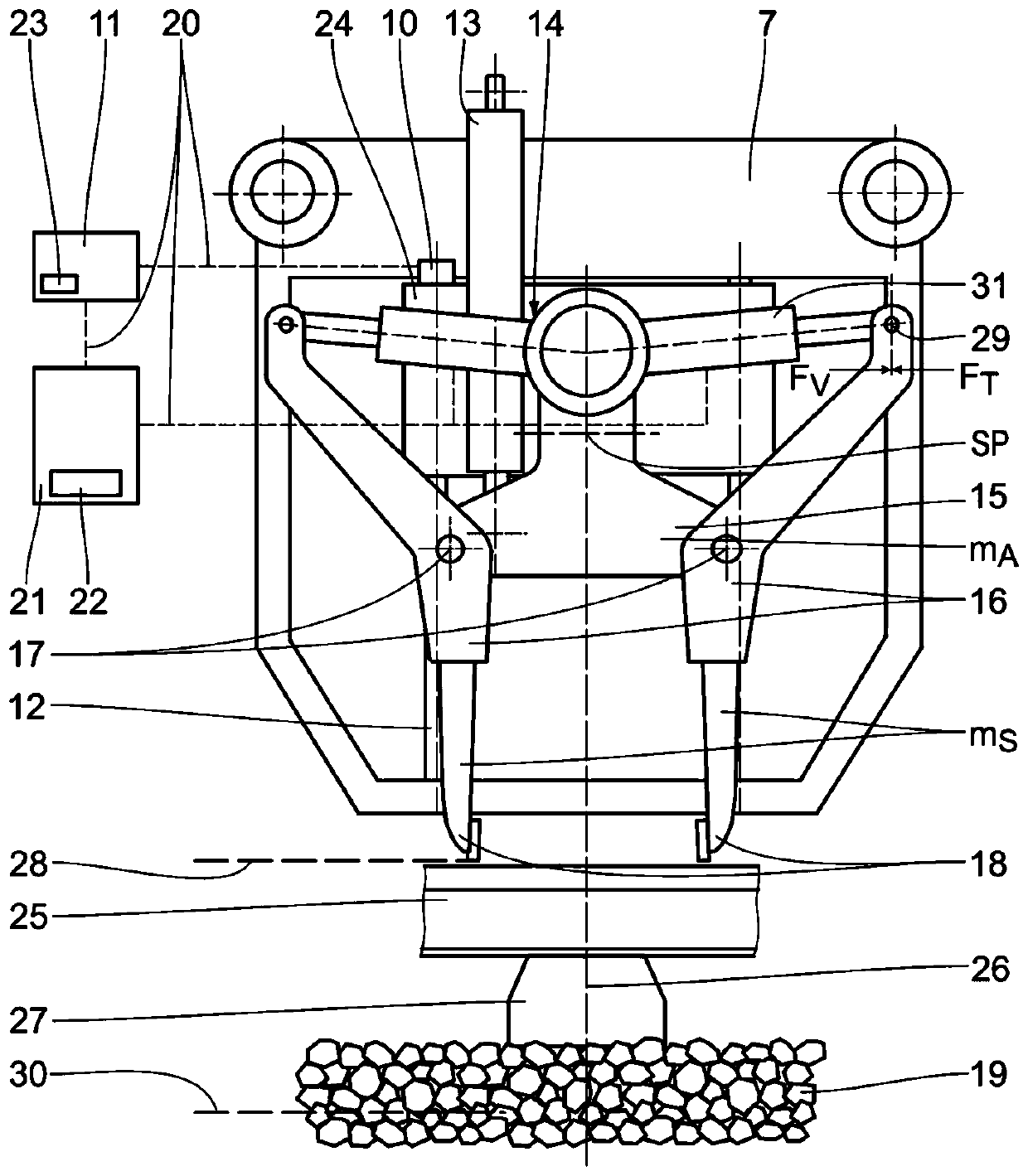

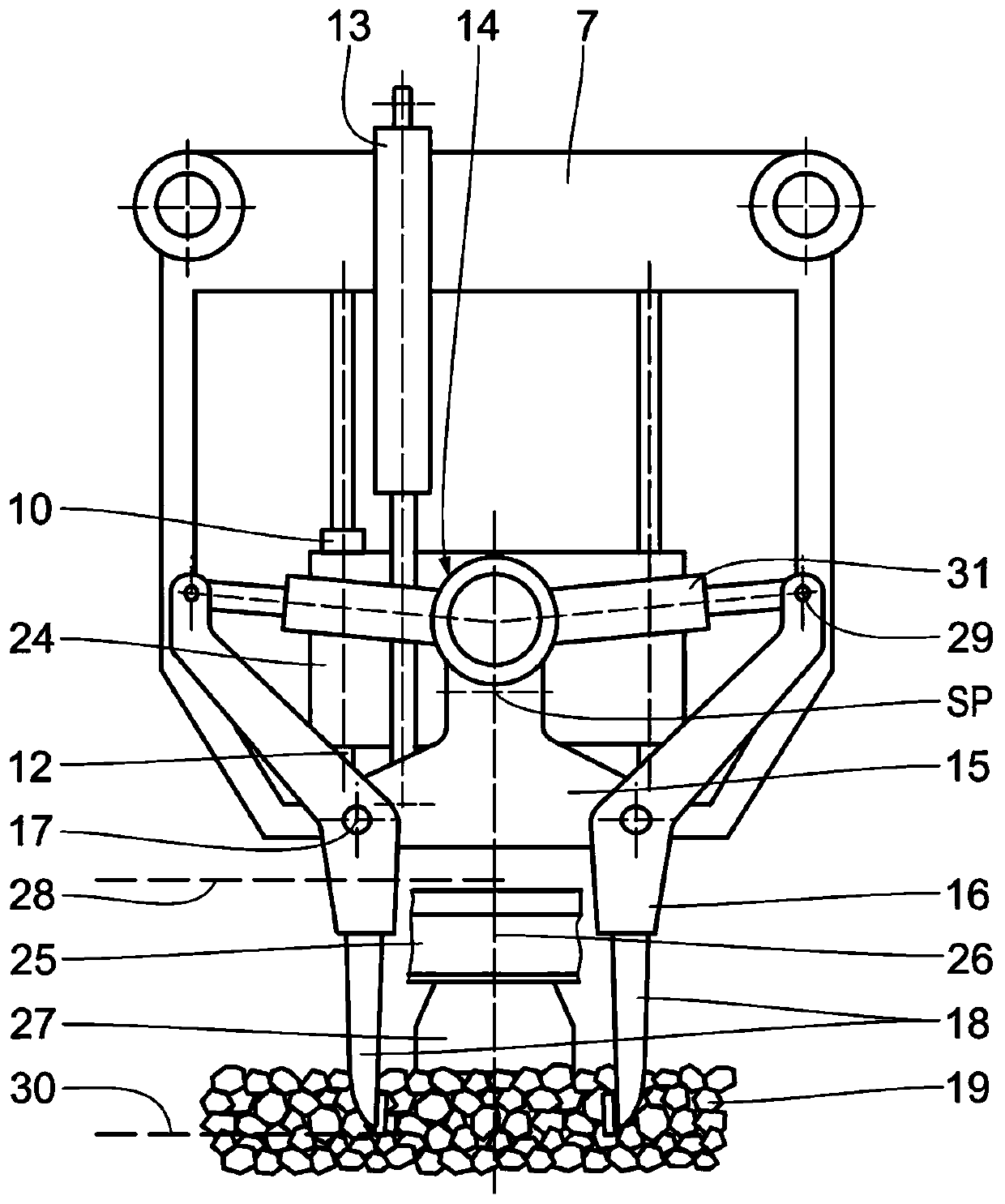

[0052] The track construction machine 1 has a machine frame 2 , at least two shafts 3 mounted on the machine frame 2 , a machine drive 4 and a tamping device 5 for compacting the track bed. The shafts 3 are arranged at a distance from one another in the horizontal x-direction on the track construction machine 1 . The x-direction and the vertical z-direction and the horizontal y-direction together form a coordinate system that is fixed relative to the machine. Wheels 6 , which can be guided by guide rails, are rotatably mounted on the shaft 3 . The machine drive 2 is designed to drive a wheel 6 of at least one of the shafts 3 in rotation.

[0053] The tamping device 5 has a unit carrier 7 , a tamping unit 8 mounted on the unit carrier 7 , a drive unit 9 , a sensor 10 and an evaluation unit 11 . A linear guide 12 is arranged between the unit carrier 7 and the tamping unit 8 . The tamping unit 8 is displaceably movable in the z-direction relative to the unit carrier 7 via line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com