Mud scraper for settling pond of water purification plant

A technology of sedimentation tank and mud scraper, which is applied in the direction of sedimentation separation, feeding/discharging device of sedimentation tank, sedimentation tank, etc., which can solve the problems of frequent maintenance, waste of resources, and blockage of mud discharge pipes, etc., to facilitate repeated use , easy to clean and avoid clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

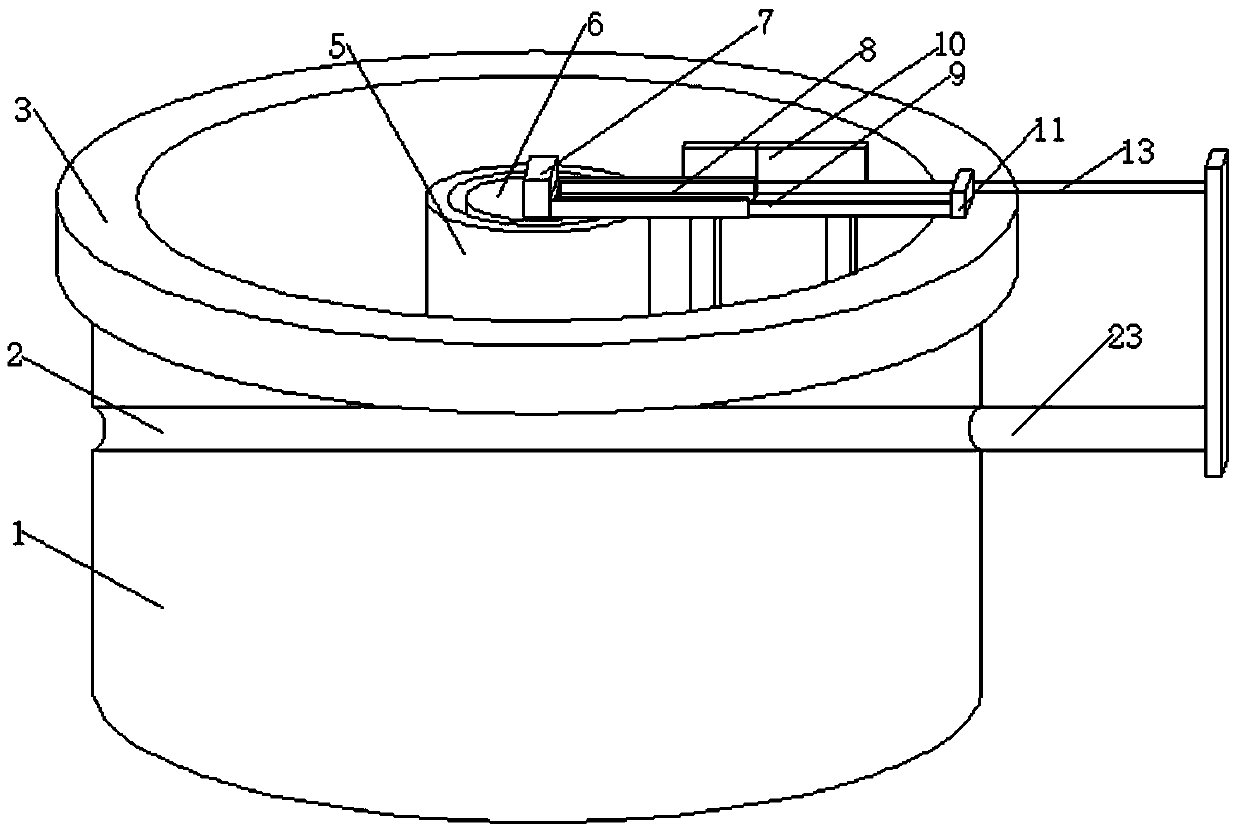

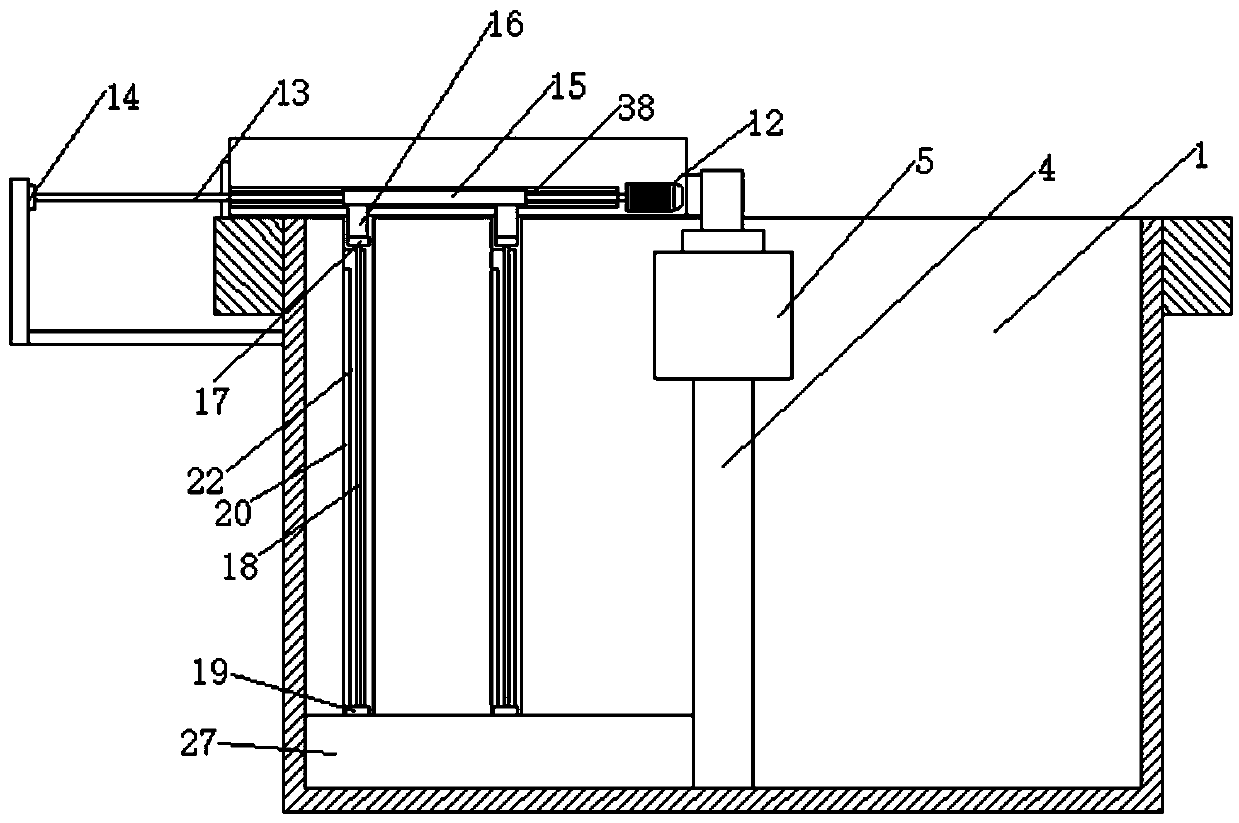

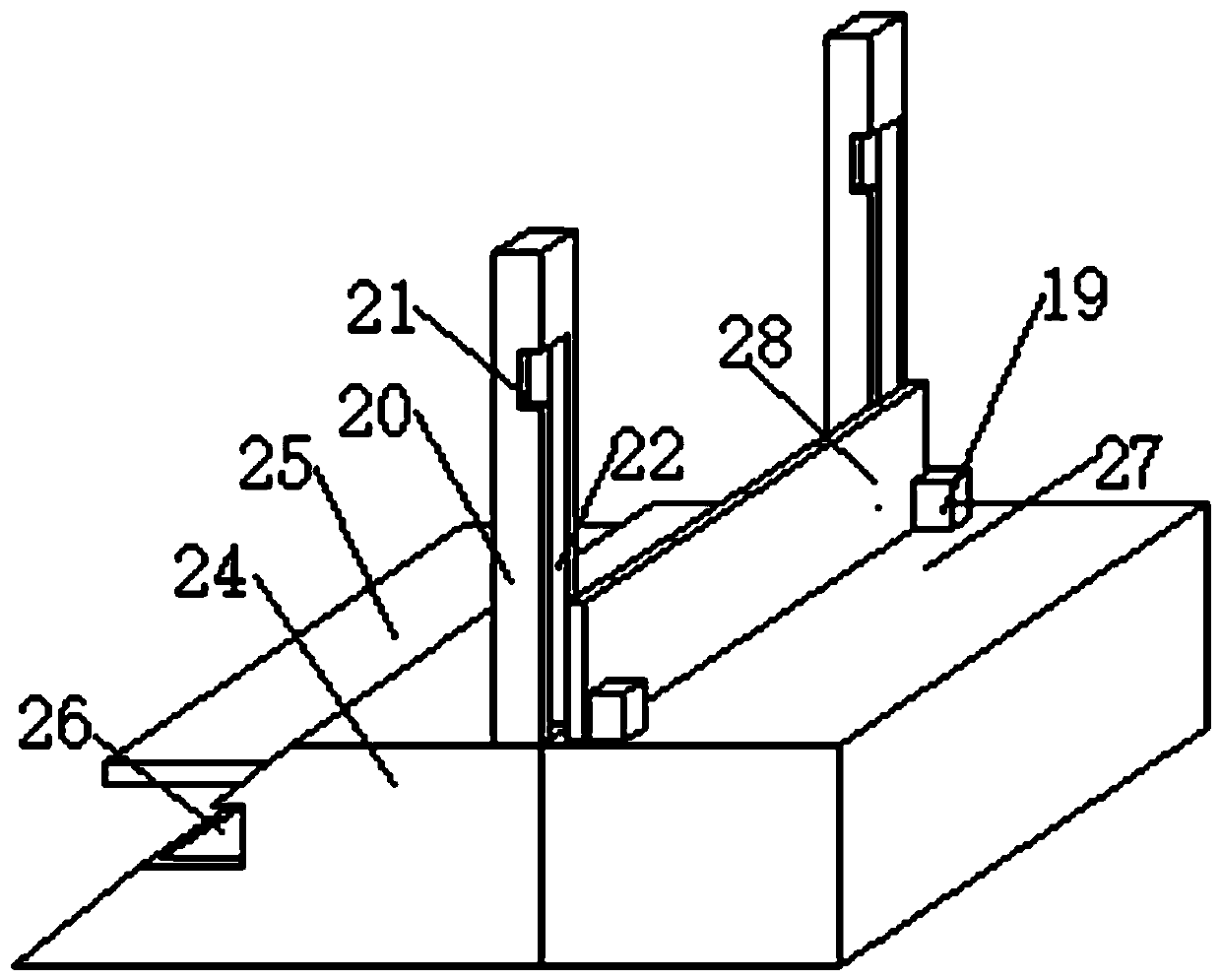

[0031] like Figure 1-6As shown, a mud scraper for the sedimentation tank of a water purification plant, including a sedimentation tank (1), the upper surface of the sedimentation tank (1) is provided with a movable platform (3), and the side of the sedimentation tank (1) is provided with sliding The tank (2), the center of the bottom of the sedimentation tank (1) is provided with a support column (4), the top of the support column (4) is provided with a mounting seat (5), and the interior of the mounting seat (5) is provided with a driving device (6 ), a connecting piece (7) is arranged above the driving device (6), a fixing plate (8) is arranged on one side of the connecting piece (7), and an extension plate (9) is inserted into one end of the fixing plate (8), and the extension plate (9) There are springs on both sides of one end of the fixed plate (8), and the other end of the spring is set on the slider. When the fixed plate (8) rotates, the springs are used to slow down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com