Abutting joint device of two-stage engine combustion chamber

An engine and combustion chamber technology, applied in the field of docking devices for two-stage engine combustion chambers, can solve problems such as the assembly process of two-stage engine combustion chambers, solve labor intensity problems and manual operation safety problems, improve docking accuracy, Quick and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described, it should be noted that the present invention is not limited to the following specific examples, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

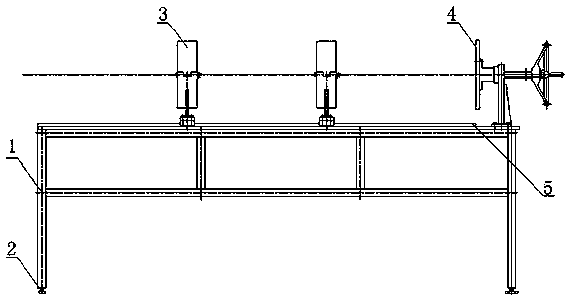

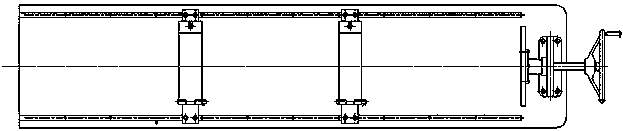

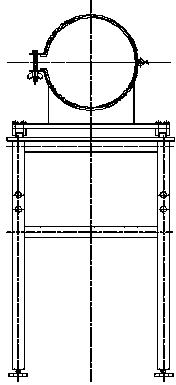

[0014] as follows Figure 1-3 As shown, a docking device for a two-stage engine combustion chamber with a diameter of less than 600mm is assembled.

[0015] The height of the support platform 1 is 820mm, and two sets of holes are drilled in parallel on the two support legs on the left side of the support platform 1 to connect two sets of the same devices; the bottom of the support platform 1 is equipped with an adjustment block 2, which is supported by the thread and the support platform The legs are connected to adjust the levelness of the support platform 1; two linear guide rails 5 are installed above the support platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com