Ball mill tube, ball mill with ball mill tube and manufacturing method of ball mill

A ball mill and cylinder technology, applied in the field of mining machinery related technical equipment, can solve the problems of difficult processing, poor concentricity of the horizontal cylinder, and high construction cost, and achieve the effects of reducing production cost and difficulty, small driving force, and improving precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

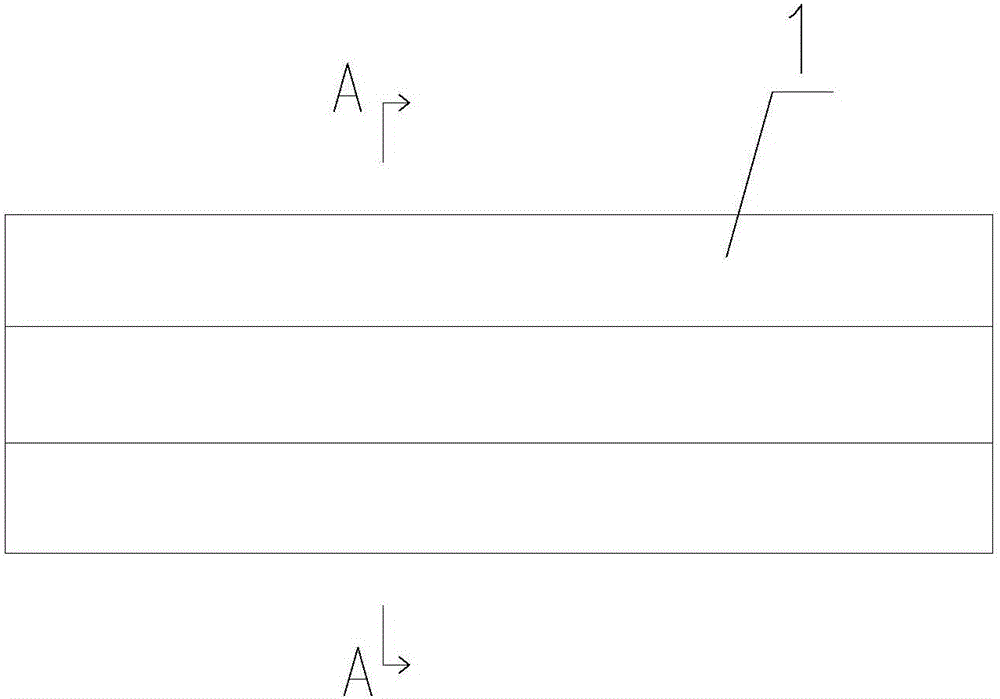

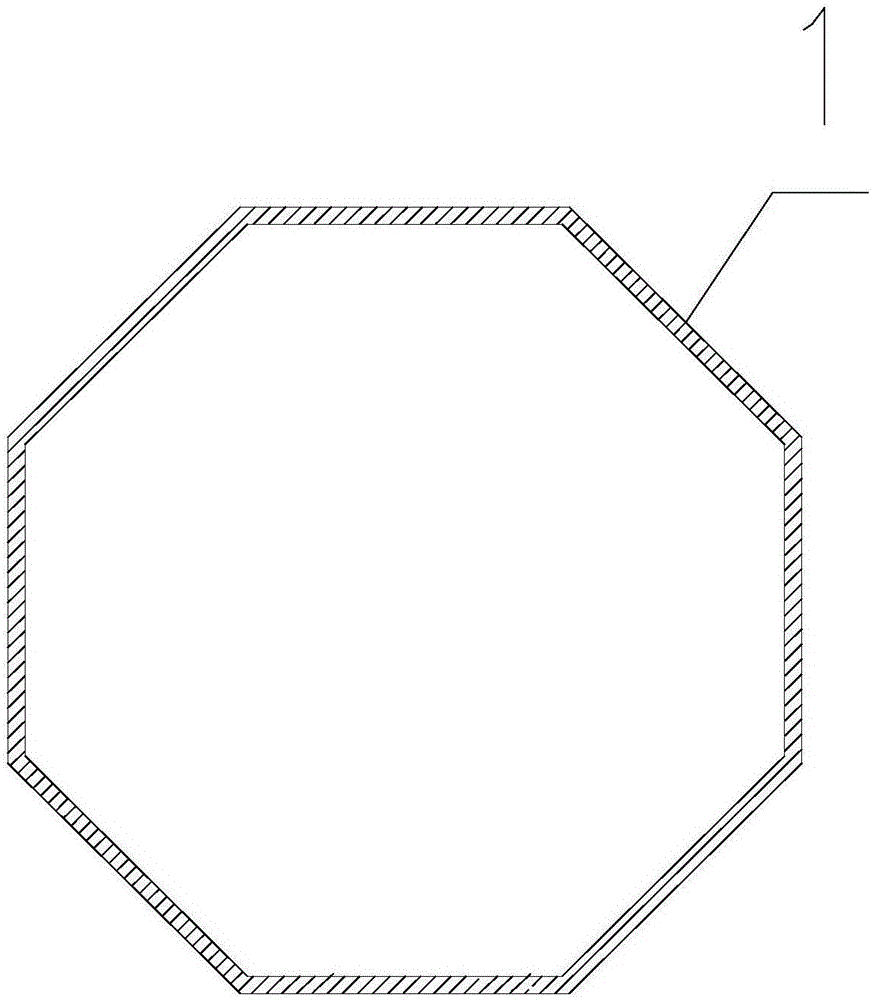

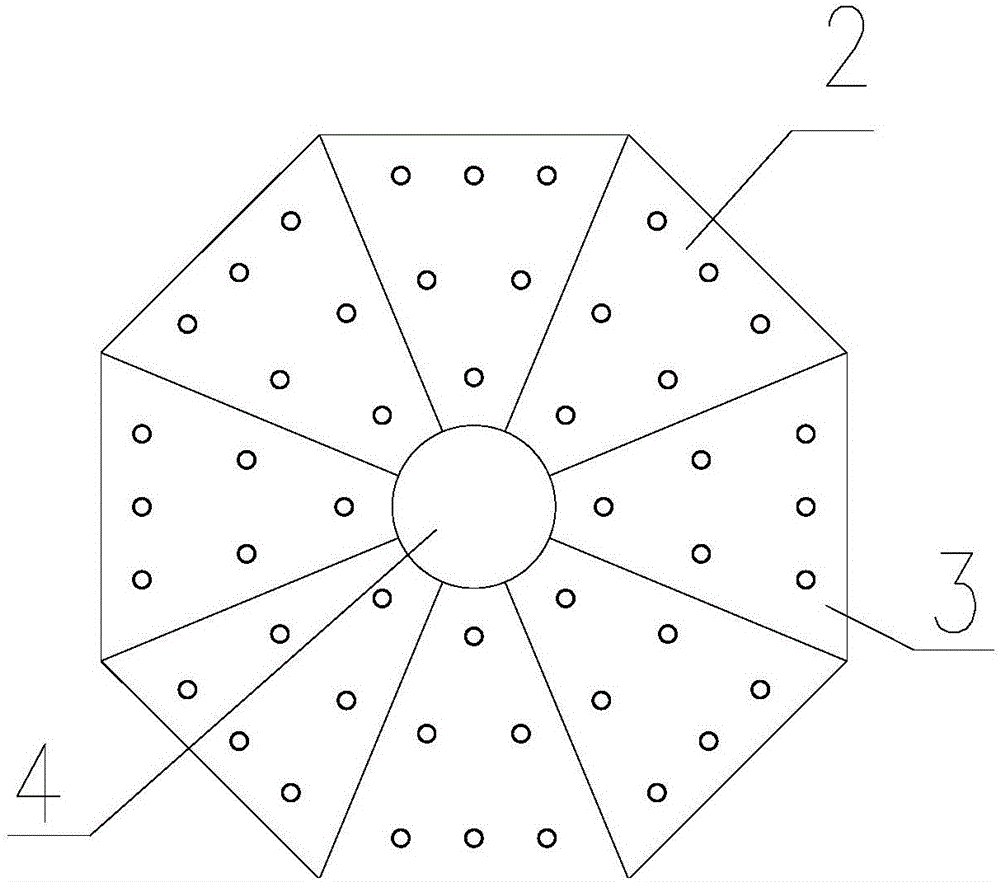

[0040] Embodiment: a kind of ball mill barrel, its structure reference Figure 1-3 As shown, it includes an end liner 2 and a plurality of cylinder liner 1 fixedly connected to the edge of one side of the end liner 2;

[0041] The end liner 2 has a polygonal structure, and the space formed by the end liner 2 and the cylinder liner 1 is a ball mill for materials; the end liner 2 is welded by a plurality of base plates 3 with the same structure.

[0042] Preferably, the barrel of the ball mill is a regular polygonal structure. Such as regular hexagonal, regular octagonal or regular dodecagonal structures.

[0043] The best choice is that the ball mill and the barrel have an octagonal structure. That is: the outer edges of the end linings 2 at both ends are octagonal structures, and the eight sides of the end linings 2 are respectively fixedly connected with a rectangular cylinder lining 1, and the adjacent cylinder linings 1 are welded to form confined space. Wherein, there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com