Non-standard part machining clamp for precision machine tool

A technology of parts processing and precision machine tools, which is applied in the field of non-standard parts processing fixtures, can solve the problems of affecting tool positioning accuracy, machining accuracy, difficulty in achieving high-precision positioning and clamping, and low positioning accuracy, so as to solve the problem of poor positioning accuracy. High, achieve accurate positioning, improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

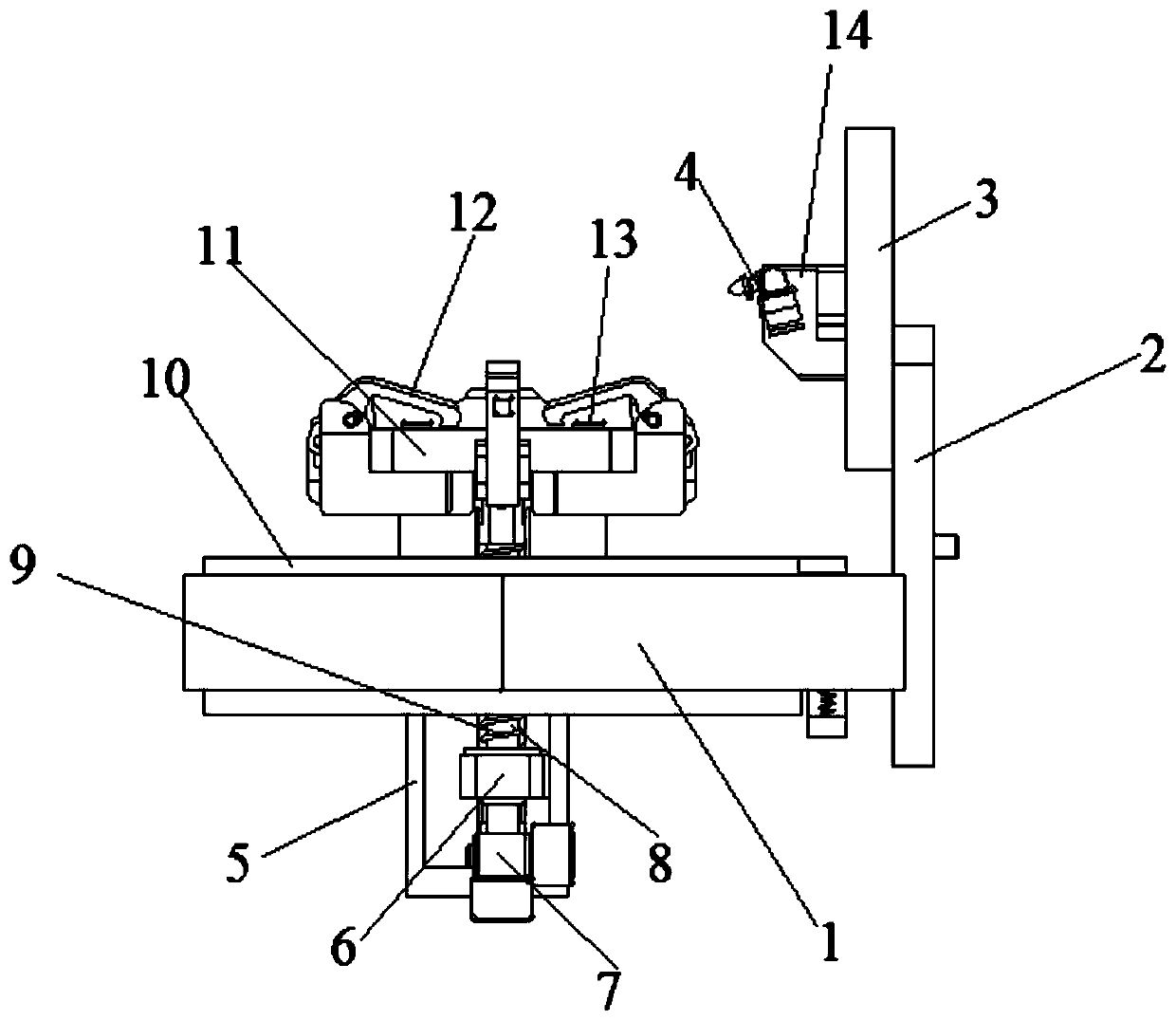

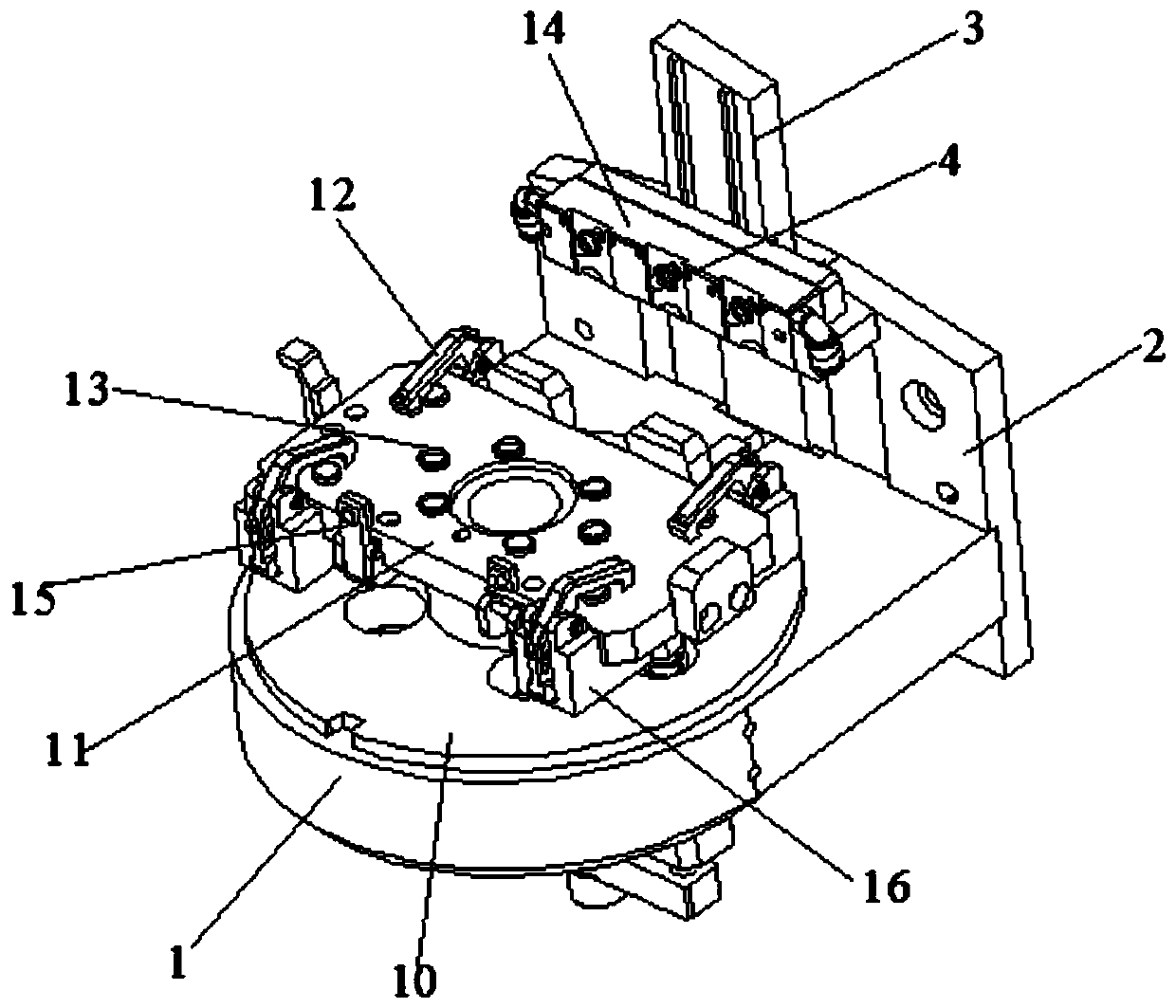

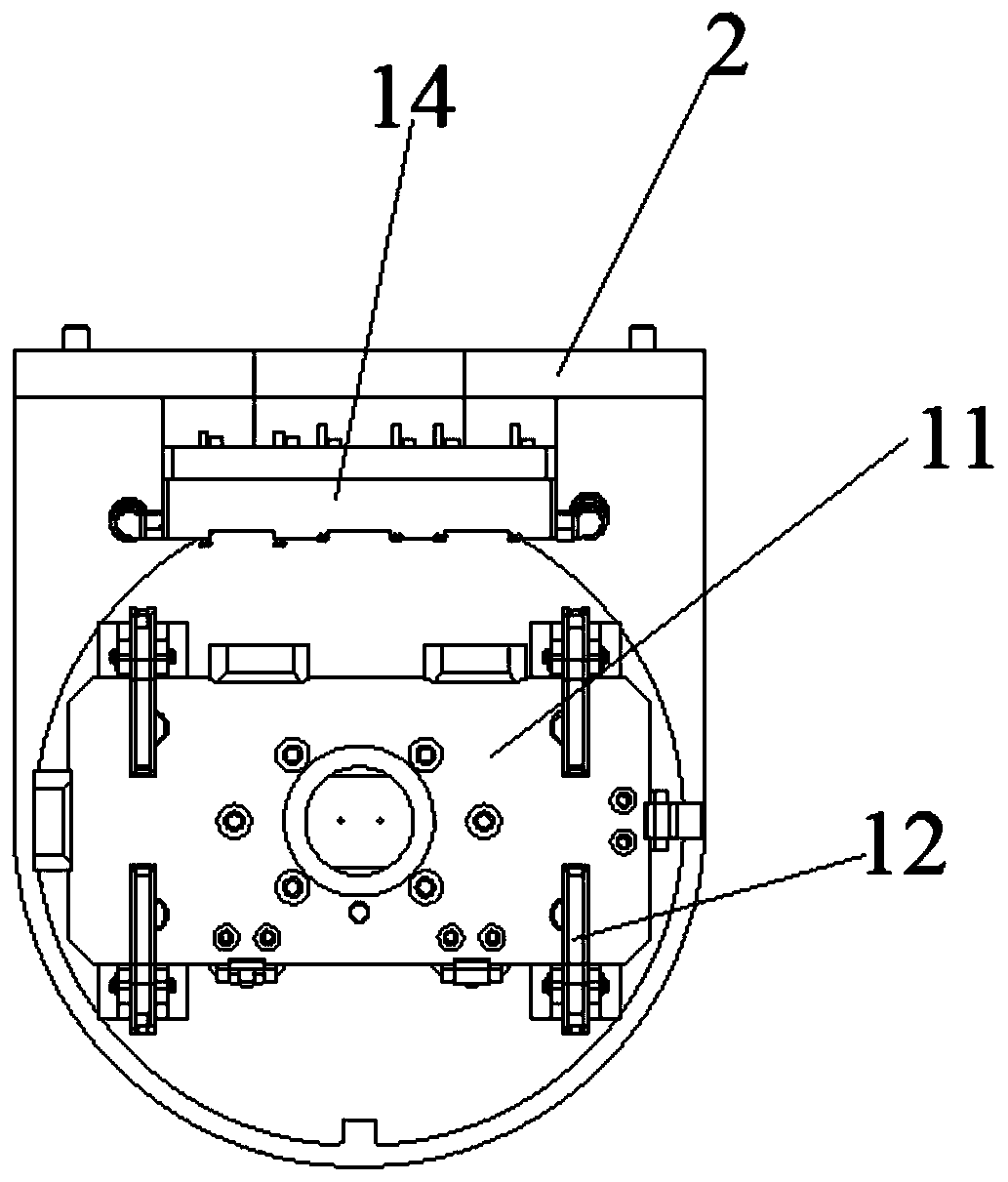

[0026] see Figure 1-6 , in an embodiment of the present invention, a non-standard part processing fixture for precision machine tools, which includes a base 1, a column 2, a visual inspection mechanism 14, a turntable 10, a positioning clamp seat 16, a clamping table 11, a compensation support adjustment Mechanism 13 and pressing mechanism, wherein, one side of the horizontally arranged base 1 is provided with the vertically extending column 2, and the top of the base 1 is provided with a rotatable turntable 10, which is characterized in that, The visual detection mechanism 14 is arranged on the upright adjustable position on the column, the positioning holder 16 is fixedly arranged on the turntable 10, and the clamping table 11 is positioned on the positioning holder 16, The pressing mechanism is arranged around the clamping platform, and a plurality of compensation support adjustment mechanisms protruding upward from the top table of the clamping platform are arranged insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com