Constant-tension pay-off device

A wire pay-off device and constant tension technology, applied in the field of railway guide erection, can solve the problems of reducing the quality of the bearing wire, affecting the quality of the bearing wire, complex structure of the bracket, etc., and achieving simple and convenient installation and disassembly, high degree of automation, and stable tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

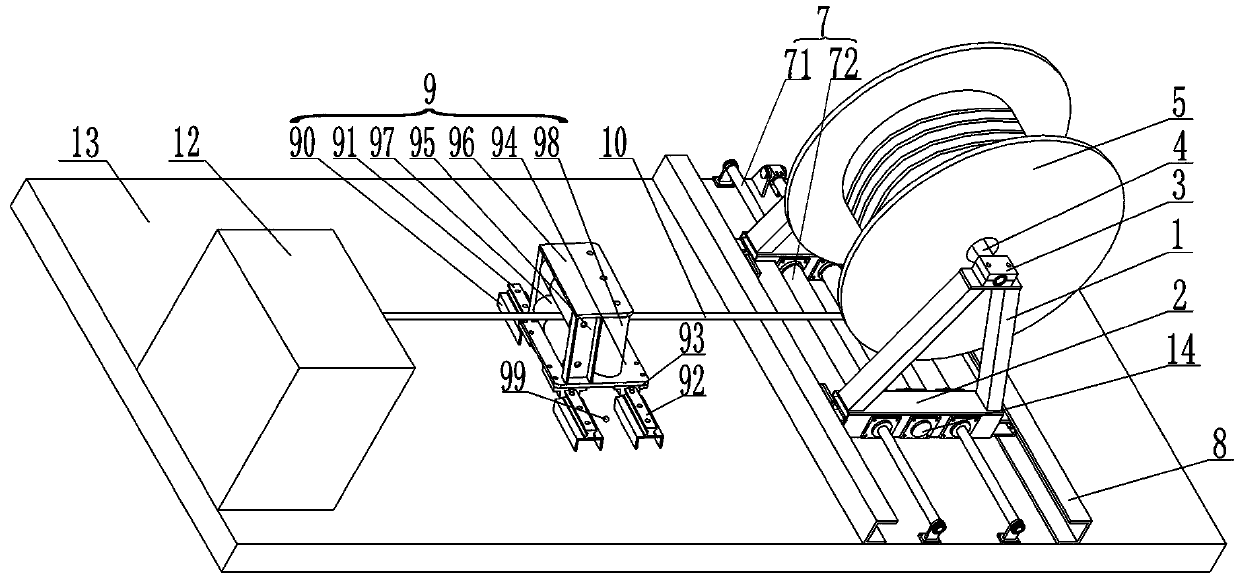

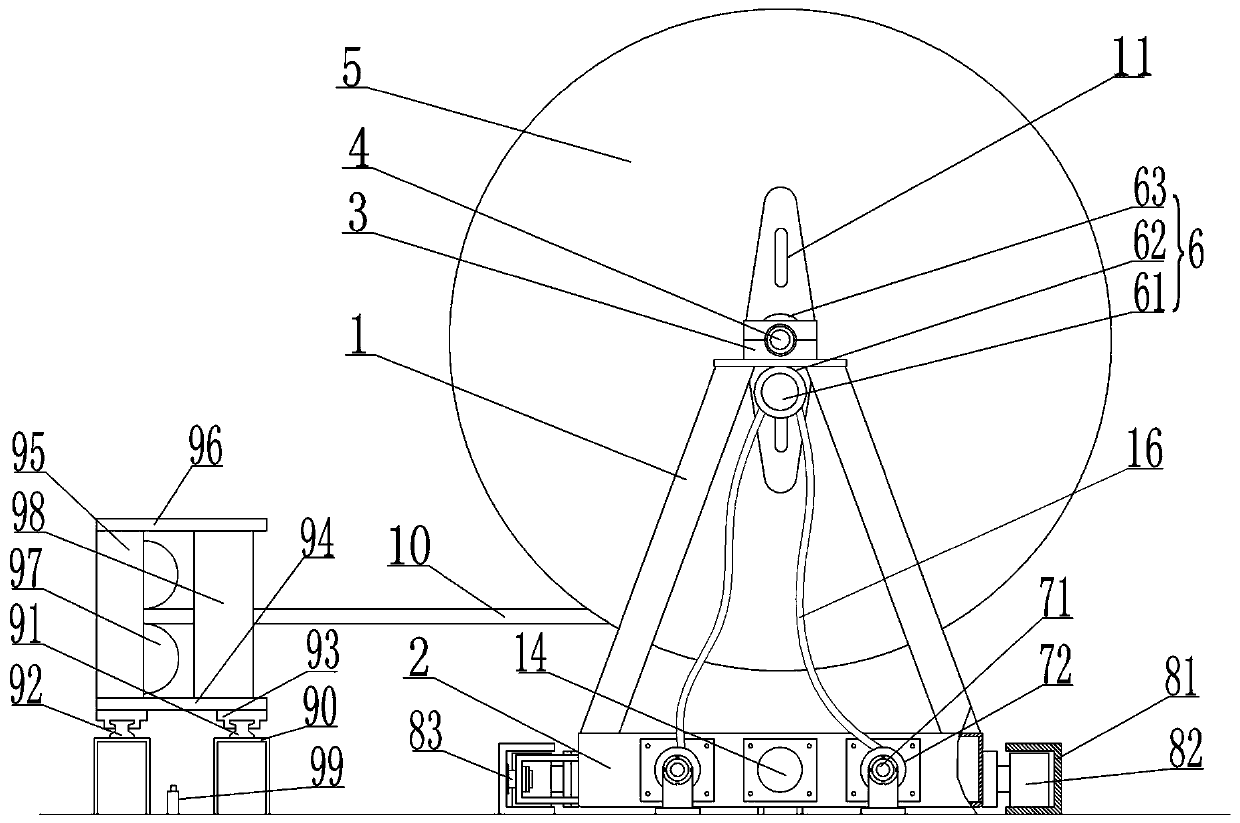

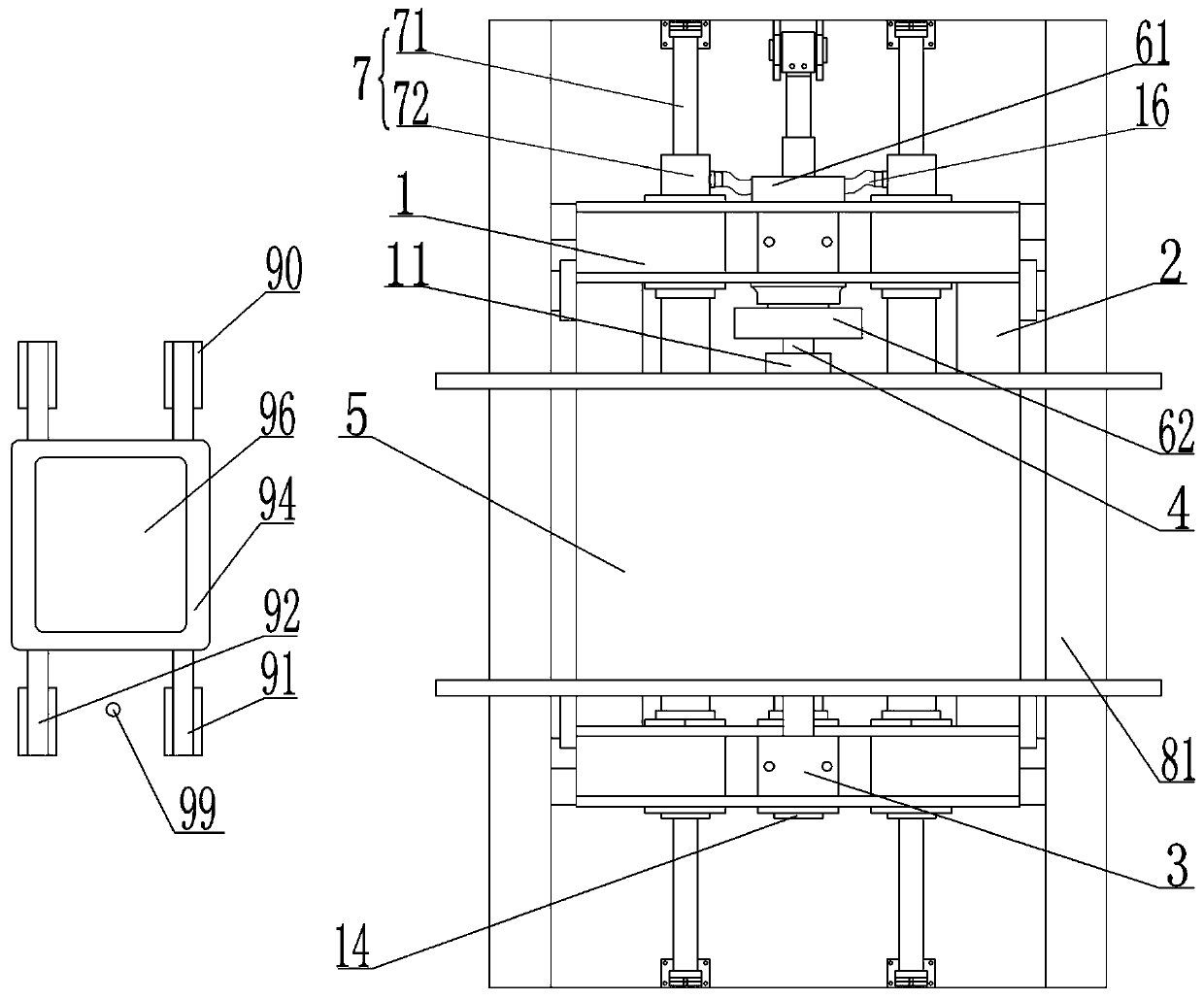

[0034] Example Constant tension pay-off device

[0035] This example Figure 1-Figure 5 As shown, a constant tension pay-off device includes a support 1, a rotating shaft 4 rotatably connected to the support 1, a winding device 5 fixed on the rotating shaft 4 for winding the bearing wire 10, and the support 1 is two The trapezoidal structures arranged in parallel are formed, the upper part is narrow and the lower part is wider, and the lower parts are connected together by the welded base 2 . The top of the bracket 1 is detachably provided with two bearing seats 3, the bearing seats 3 are respectively arranged on two parallel trapezoidal structures of the bracket 1, and the rotating shaft 4 is connected to the bearing seats 3 through bearing rotation, The two ends of the rotating shaft 4 are respectively arranged on the two bearing seats 3 . The bearing seat 3 is composed of upper and lower parts, which are fastened to each other on the rotating shaft 4, and the two parts ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com